Red optical color-changing sheet and preparation method thereof

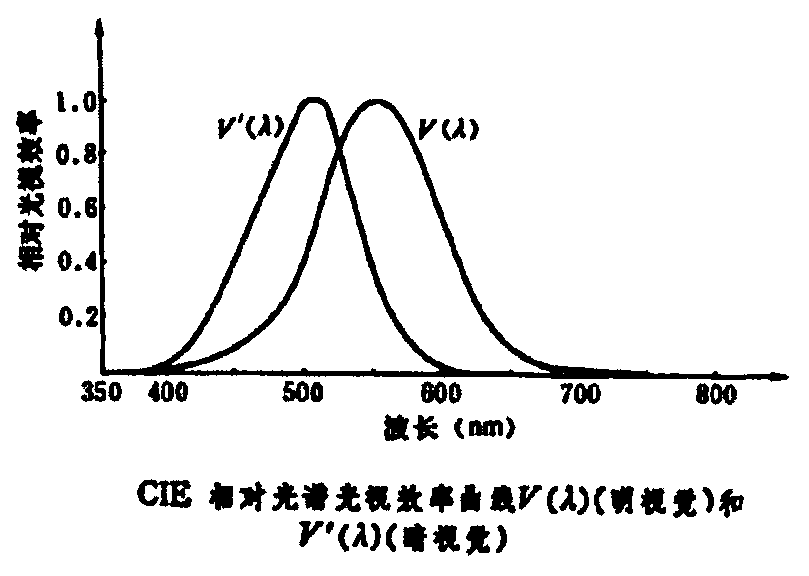

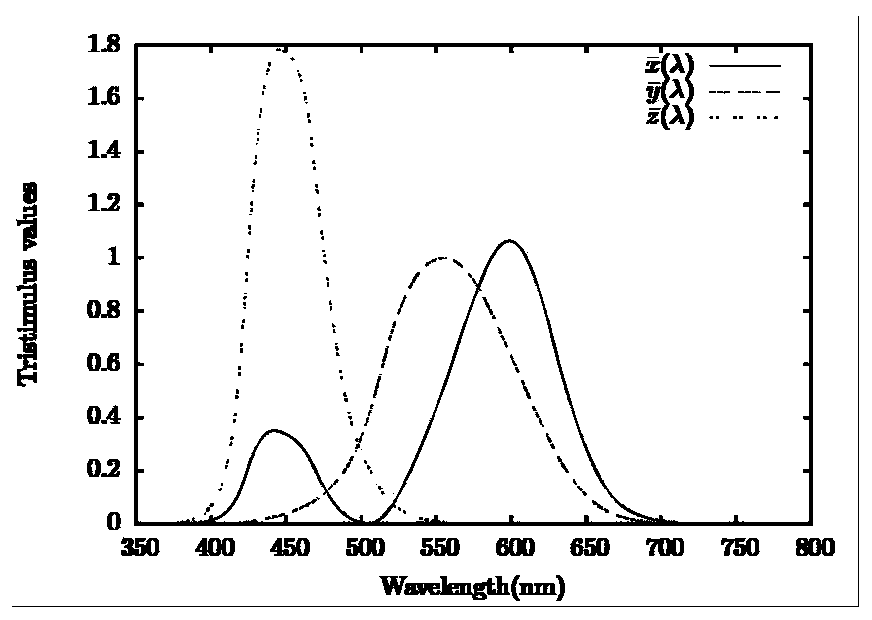

A thin-film, optical technology, applied in optics, optical components, instruments, etc., can solve the problems of low visual efficiency, affecting the number of cycles, large stress in the film, etc., to ensure color purity and discoloration performance, increase color saturation, The effect of reducing the half-wave width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A red optical color-changing sheet, the sheet has a central reflective layer, and a first dielectric layer, a first metal light-splitting layer, and a second dielectric layer are arranged symmetrically outward from the central reflective layer, and the specific film structure is as follows:

[0054] The second dielectric layer D2: Fe 2 o 3 -50nm

[0055] The first metal light splitting layer M1:Ti-19nm

[0056] The first dielectric layer D1:MgF 2 -170nm

[0057] Central reflection layer MR: Cu-100nm

[0058] The first dielectric layer D1:MgF 2 -170nm

[0059] The first metal light splitting layer M1:Ti-19nm

[0060] The second dielectric layer D2: Fe 2 o 3 -50nm.

[0061] Among them, the central reflective layer provides reflection, the dielectric layer determines the position of the main peak, the first metal light splitting layer, the second dielectric layer and the subsequent layers all play the role of reducing the half-wave width, improving color purity, ...

Embodiment 2

[0077] A red optical color-changing sheet, the sheet has a central reflective layer, and a first dielectric layer, a first metal light-splitting layer, and a second dielectric layer are arranged symmetrically outward from the central reflective layer, and the specific film structure is as follows:

[0078] The second dielectric layer D2: Fe 2 o 3 -52nm

[0079] Metal splitting layer M1:Ti-25nm

[0080] The first dielectric layer D1:TiO 2 -100nm

[0081] Central reflection layer MR: Ni-100nm

[0082] The first dielectric layer D1:TiO 2 -100nm

[0083] Metal splitting layer M1:Ti-25nm

[0084] The second dielectric layer D2: Fe 2 o 3 -52nm.

[0085] Among them, the central reflective layer MR in this embodiment can also adopt a layered or alloy structure of Cr, Ti, Ni, Fe, Mn, Co, Zr, Mo, W, Sm, and the first dielectric layer can also use SiO, SiO 2 、Al 2 o 3 、TiO X , LiTiO x 、 Ta 2 o 5 , ZrO 2 , Nb 2 o 5 , HfO 2 , Sb 2 o 3 , Fe 2 o 3 , CuO, NiO, Sm 2 o...

Embodiment 3

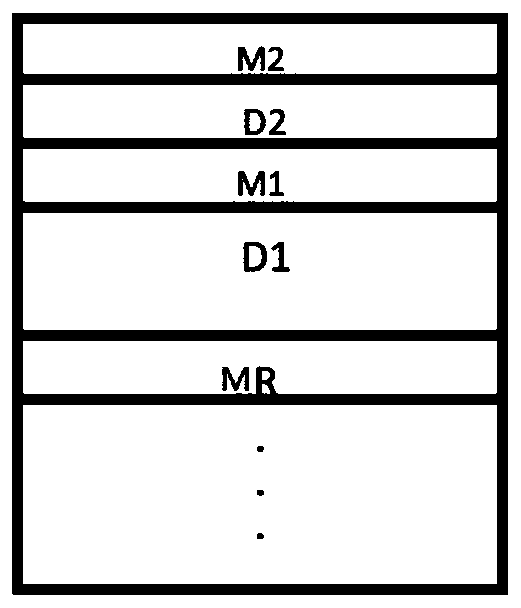

[0089] A red optically-chromic flake, such as image 3 As shown, the sheet has a central reflection layer, and the first dielectric layer, the first metal light-splitting layer, the second medium layer, and the second metal light-splitting layer are arranged symmetrically outward from the central reflection layer. The specific film structure is as follows:

[0090] The second metal light splitting layer M2: Cr-4nm

[0091] The second dielectric layer D2: Fe 2 o 3 -60nm

[0092] The first metal light splitting layer M1: Cu-38nm

[0093] The first dielectric layer D1:MgF 2 -195nm

[0094] Central reflection layer MR: Cu-150nm

[0095] The first dielectric layer D1:MgF 2 -195nm

[0096] The first metal light splitting layer M1: Cu-38nm

[0097] The second dielectric layer D2: Fe 2 o 3 -60nm

[0098] The second metal light splitting layer M2: Cr-4nm.

[0099] Figure 11 It is the reflectance spectrum of the 9-layer red optically variable sheet structure of this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com