Preparation method and application of conductive adhesive based on reinforced polysulfide ion adsorption

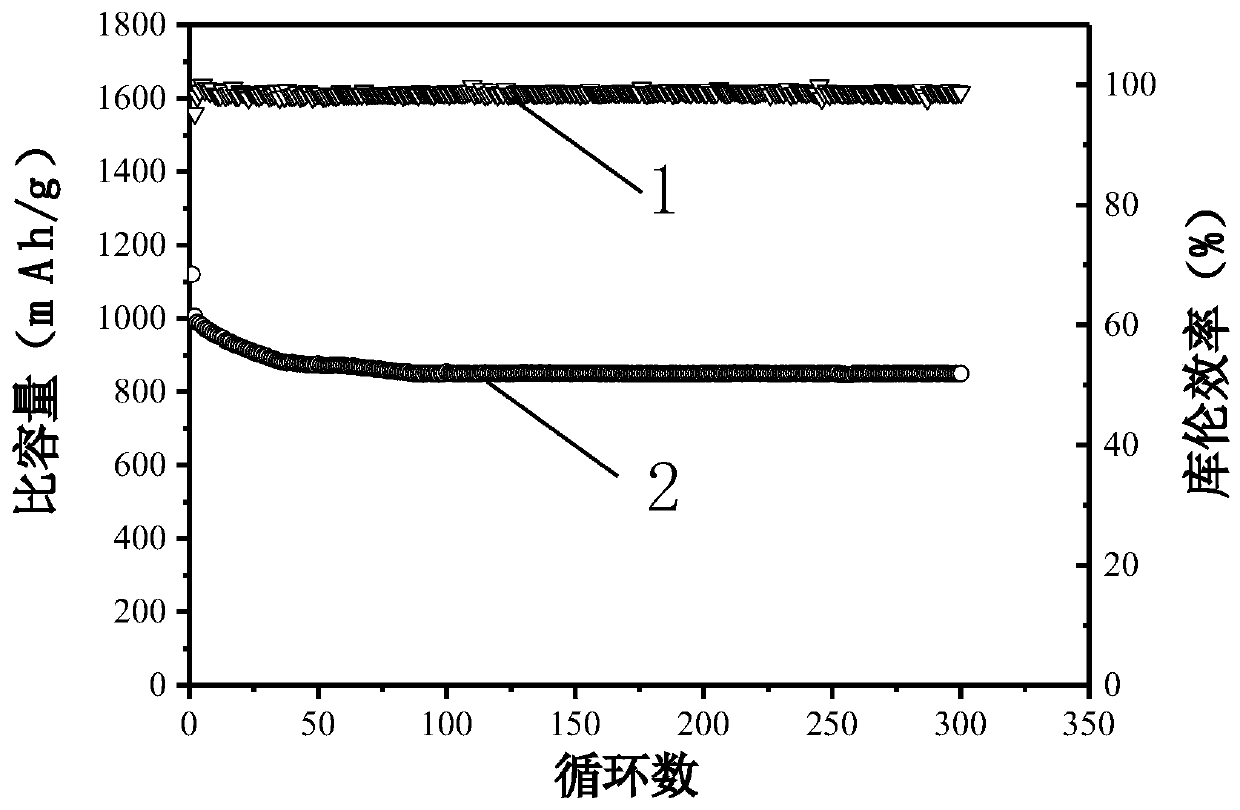

A conductive binder and ion adsorption technology, which is applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems that active materials are difficult to be fully utilized, battery charging efficiency is reduced, etc., to achieve inhibition of polysulfide ion shuttle, excellent conductivity , the effect of improving life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the preparation of aniline solution

[0031] 2 g of aniline was dissolved in 98 mL of deionized water, and dispersed by ultrasonic vibration (ultrasonic frequency 40 kHz) for 5 minutes to obtain an aniline solution with a concentration of 2 wt%.

Embodiment 2

[0032] Example 2: Preparation of cyclodextrin inclusion compound of aniline

[0033] 3.5 g of aniline was dissolved in 96.5 mL of deionized water, and dispersed by ultrasonic vibration (ultrasonic frequency 40 kHz) for 5 minutes to obtain an aniline solution with a concentration of 3.5 wt%.

[0034] Take 40mL of deionized water to dissolve 2gβ-cyclodextrin, add aniline solution, and disperse for 30 minutes with ultrasonic vibration (ultrasonic frequency 40kHz), the aniline molecules enter the cyclodextrin cavity to form an aniline cyclodextrin inclusion compound, and after vacuum drying, we get Aniline cyclodextrin inclusion complex.

Embodiment 3

[0035] Example 3: Cyclodextrin inclusion compound polymerization of aniline

[0036] At room temperature, 5 g of aniline was dissolved in 95 mL of deionized water, and ultrasonic vibration (ultrasonic frequency 40 kHz) was dispersed for 5 minutes to obtain an aniline solution with a concentration of 5 wt%. After dissolving 5 g of β-cyclodextrin in 40 mL of deionized water, the aniline solution was added. Ultrasonic vibration (ultrasonic frequency 40kHz) disperses for 30 minutes, aniline molecules enter the cyclodextrin cavity to form an aniline cyclodextrin inclusion compound, and after vacuum drying, the aniline cyclodextrin inclusion compound is obtained;

[0037] The above-mentioned aniline-cyclodextrin inclusion compound and deionized water were prepared to prepare an aniline-cyclodextrin inclusion compound solution with a concentration of 2 wt%. Take 5mL of hydrogen peroxide (3wt%) and slowly add it dropwise to 100mL of the above-mentioned aniline-cyclodextrin inclusion c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com