Waste gas purification device for sewage treatment station of sterile bulk drug production line

A waste gas purification device and sewage treatment station technology, which is applied in the direction of gas treatment, air quality improvement, chemical instruments and methods, etc., can solve the problems of large discharge, complex and changeable pollution components, and cannot be removed well, so as to achieve effective purification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

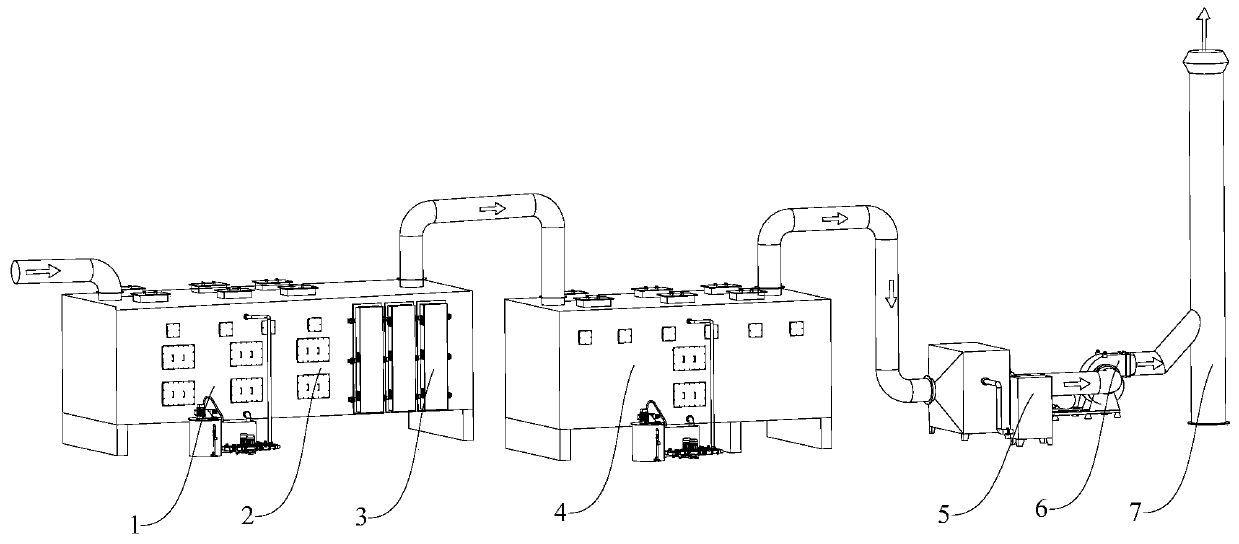

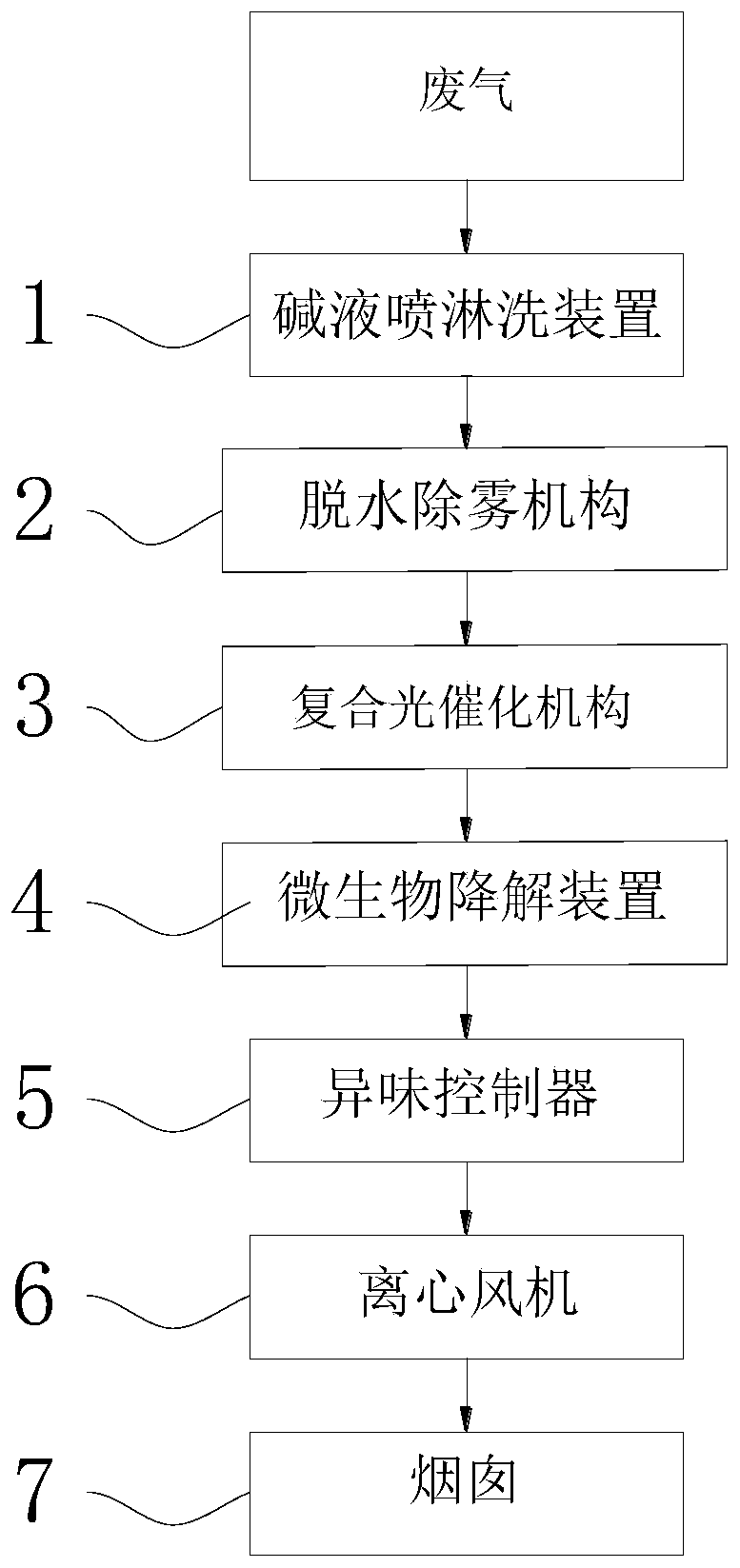

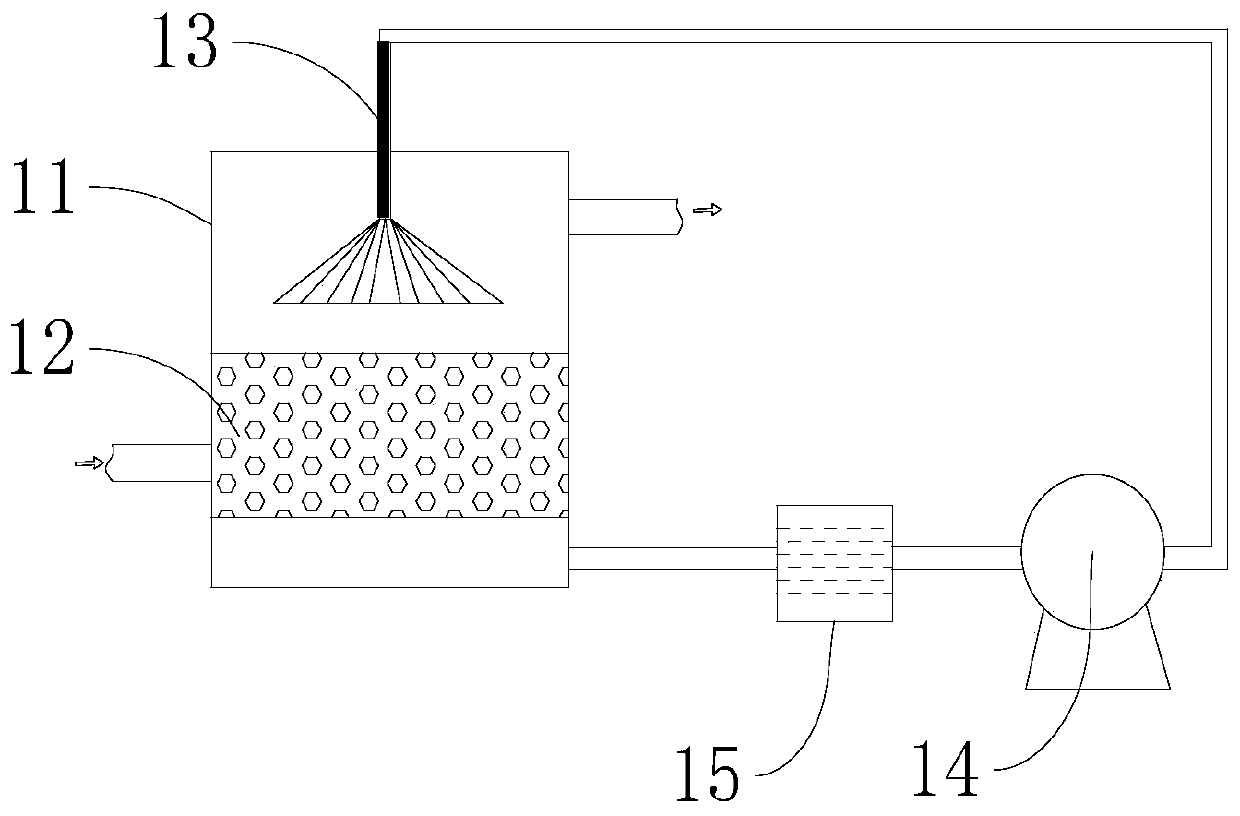

[0018] Such as Figure 1-3 Shown is a waste gas purification device of a sewage treatment station for a sterile raw material drug production line, including a lye spray washing device 1, a dehydration and demisting device 2, a composite photocatalytic device 3, a microbial degradation device 4, and odor The controller 5 and the chimney 7, the lye spray washing device 1 is used to spray alkaline liquid, the dehydration and defogging device 2 is used to dry the exhaust gas, the composite photocatalytic device 3 is used to remove volatile organic compounds in the exhaust gas, and the microbial degradation device 4 is used to degrade the exhaust gas, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com