Method for continuously producing ethylene sulfide

A continuous technology for ethylene sulfide, which is applied in the field of continuous production of ethylene sulfide, can solve the problems of quality fluctuation, intractable by-product cyanate, and high labor cost, so as to avoid production fluctuation, improve production environment, reduce The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment adopts the method of the present invention to prepare sulfide.

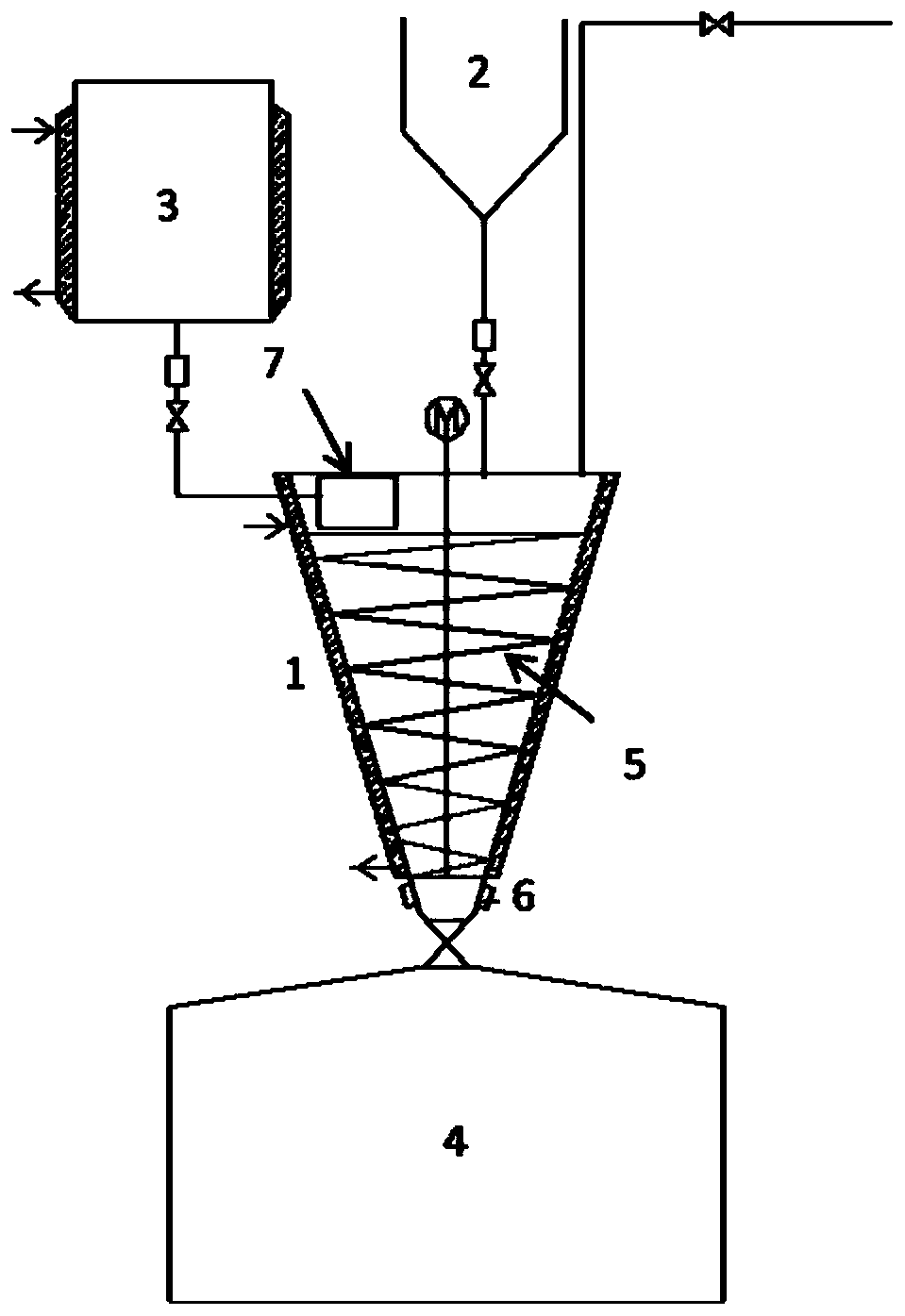

[0030] refer to figure 1 In the equipment for continuous production of sulfide shown, the continuous reactor 1 adopts the shape of an inverted cone (the ratio of the radius to the height of the upper top is 1:8). The ethylene sulfide continuous production equipment comprises: a continuous reactor 1, a feeding tank 2 connected to the upper end of the continuous reactor 1 and an insulated storage tank 3, a solid waste collector 4 connected to the lower end of the continuous reactor 1, and a solid waste collector 4 connected to the continuous reactor 1. 1. A condenser connected to the air outlet at the upper end, and a gas-liquid separator connected to the condenser.

[0031] Preheat the continuous reactor 1 to 130°C, turn on the spiral scraper 5 for stirring, and at the same time turn on the oscillator 6, sodium thiocyanate enters the continuous reactor 1 from the feeding tank 2, and ...

Embodiment 2

[0037] The present embodiment adopts the method of the present invention to prepare sulfide. Referring to Example 1 and figure 1 In the shown equipment for continuous production of sulfide, the continuous reactor adopts an inverted frustum shape with a ratio of upper top radius to height of 1:8.5.

[0038] Preheat the continuous reactor 1 to 110°C, turn on the spiral scraper 5 for stirring, and at the same time turn on the oscillator 6, sodium thiocyanate enters the continuous reactor 1 from the feeding tank 2, and ethylene carbonate is misted through the liquid atomizer 7 Add continuous reactor 1 after melting, adjust meter, make sodium thiocyanate and ethylene carbonate enter continuous reactor 1 according to molar ratio 1:1. The generated ethylene sulfide is condensed and collected in a liquid collector through a gas-liquid separator for further preparation of diethylaminoethanethiol.

[0039] After the reaction entered a steady state, the continuous 8-hour production data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com