A kind of low-frequency p-band wave-absorbing material and preparation method thereof

A wave absorbing material, P-band technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of few types and poor performance, and achieve the effects of low cost, excellent wave absorbing performance, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

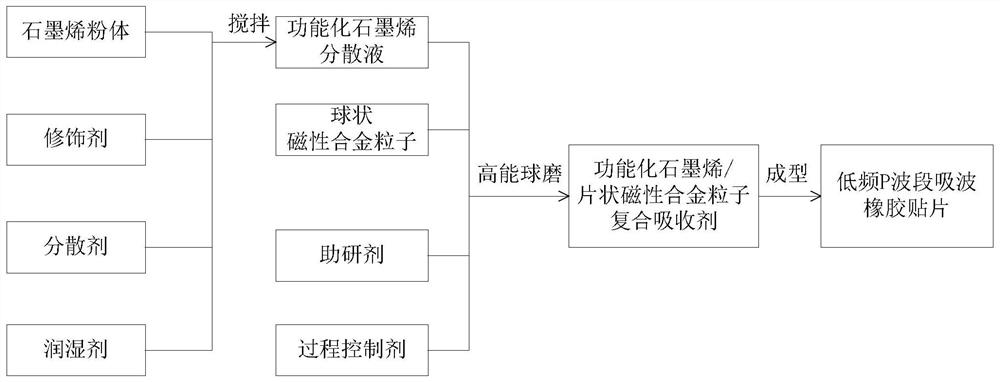

[0031] The invention provides a method for preparing a low-frequency P-band wave-absorbing material, the method comprising the following steps:

[0032] (1) Using the first surfactant to modify the graphene powder (functionalization treatment) to prepare a functionalized graphene dispersion.

[0033] (2) make described functionalized graphene dispersion liquid and spherical magnetic alloy particle to carry out composite by high-energy ball milling method, make functionalized graphene / flaky magnetic alloy particle composite absorbent; In the present invention, high-energy ball milling can provide grinding The collision force between the ball and the powder changes the shape of the magnetic alloy particles from spherical to flake.

[0034] (3) The second surfactant is used to coat the functionalized graphene / flaky magnetic alloy particle composite absorbent to obtain a low-frequency P-band absorbent; in the present invention, the time of the coating treatment For example, it is...

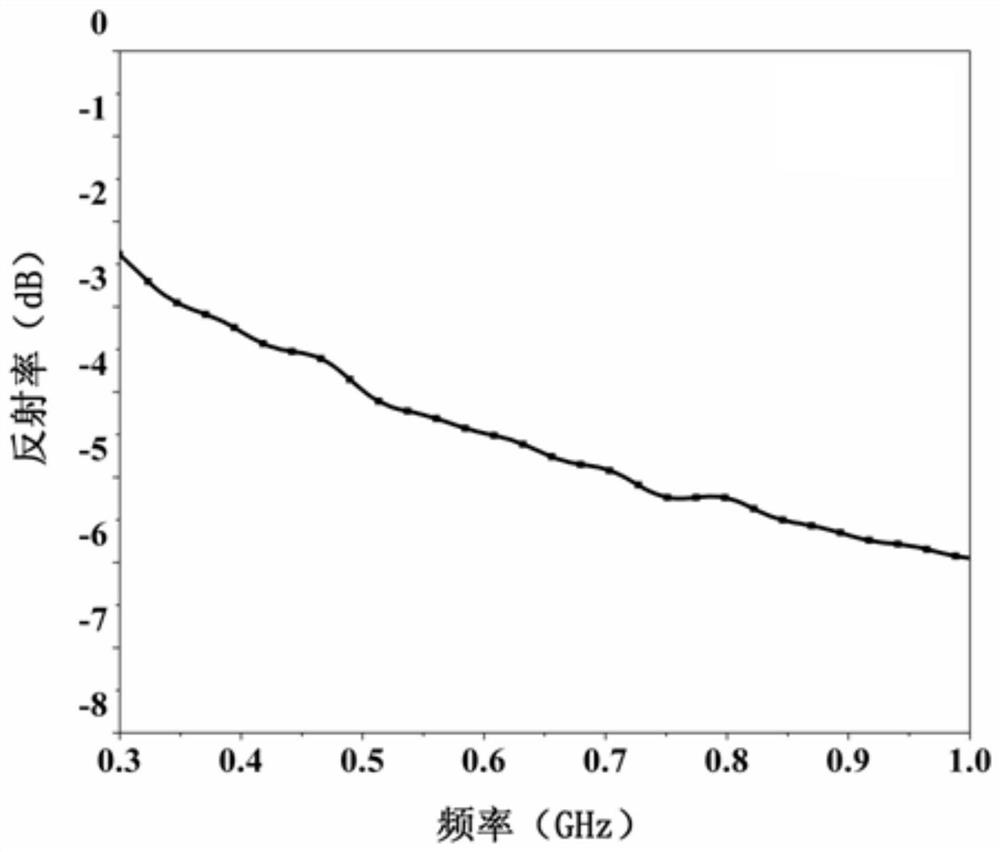

Embodiment 1

[0059] Prepare a low-frequency P-band wave-absorbing material, the preparation method is as follows:

[0060] ① Functionalized graphene dispersion: weigh 85 parts by weight of graphene powder, 7 parts by weight of KH-550 modifier, 1.7 parts by weight of ANTI-TERRA-204 dispersant, 1.3 parts by weight of BYK-181 wetting agent, and place In the absolute ethanol solvent, the homogenizer is stirred and dispersed at a high speed to obtain a uniformly mixed functionalized graphene dispersion.

[0061] ②Functionalized graphene / flaky magnetic alloy particle composite absorbent: Weigh 25 parts by weight of functionalized graphene dispersion; 65 parts by weight of spherical iron-cobalt alloy particles, 1.5 parts by weight of calcium carbonate research aid, n-butanol process 60 parts by weight of the control agent are added to the functionalized graphene dispersion, the ball-to-material ratio is 16:3, and high-energy ball milling is carried out for 10h to obtain a mixed solution containin...

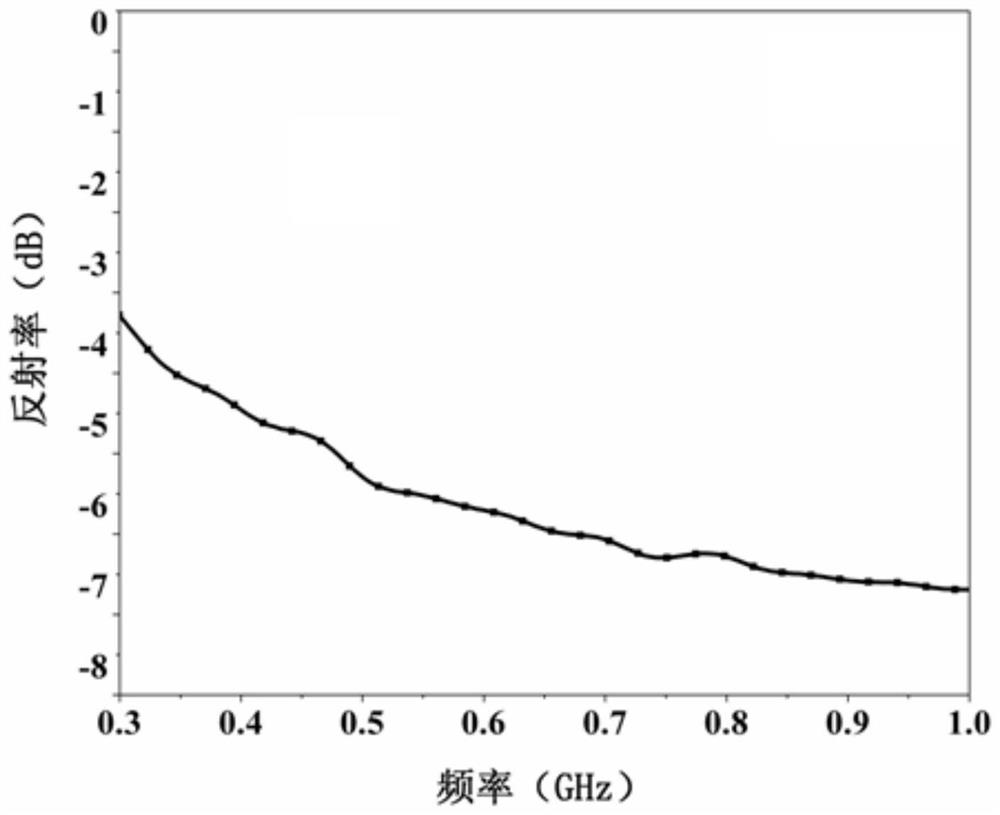

Embodiment 2

[0066] Prepare a low-frequency P-band wave-absorbing material, the preparation method is as follows:

[0067] ① Functionalized graphene dispersion: weigh 90 parts by weight of graphene powder, 6 parts by weight of KH-550 modifier, 1.5 parts by weight of ANTI-TERRA-204 dispersant, and 1.5 parts by weight of BYK-181 wetting agent, and place In the absolute ethanol solvent, the homogenizer is stirred and dispersed at a high speed to obtain a uniformly mixed functionalized graphene dispersion.

[0068] ②Functionalized graphene / flaky magnetic alloy particle composite absorbent: Weigh 25 parts by weight of functionalized graphene dispersion; 80 parts by weight of spherical iron-nickel alloy particles, 1.5 parts by weight of calcium carbonate research aid, n-butanol process 60 parts by weight of the control agent are added to the functionalized graphene dispersion, the ball-to-material ratio is 16:3, and high-energy ball milling is carried out for 10h to obtain a mixed solution conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com