Rotary steerable drilling system and its control method

A technology of rotary steerable drilling and directional well, which is applied in the automatic control system of drilling, directional drilling, rotary drilling and other directions, can solve the problems of inconvenient use and maintenance, reduce installation and use costs, and reduce directional support pressure. , the effect of increasing drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

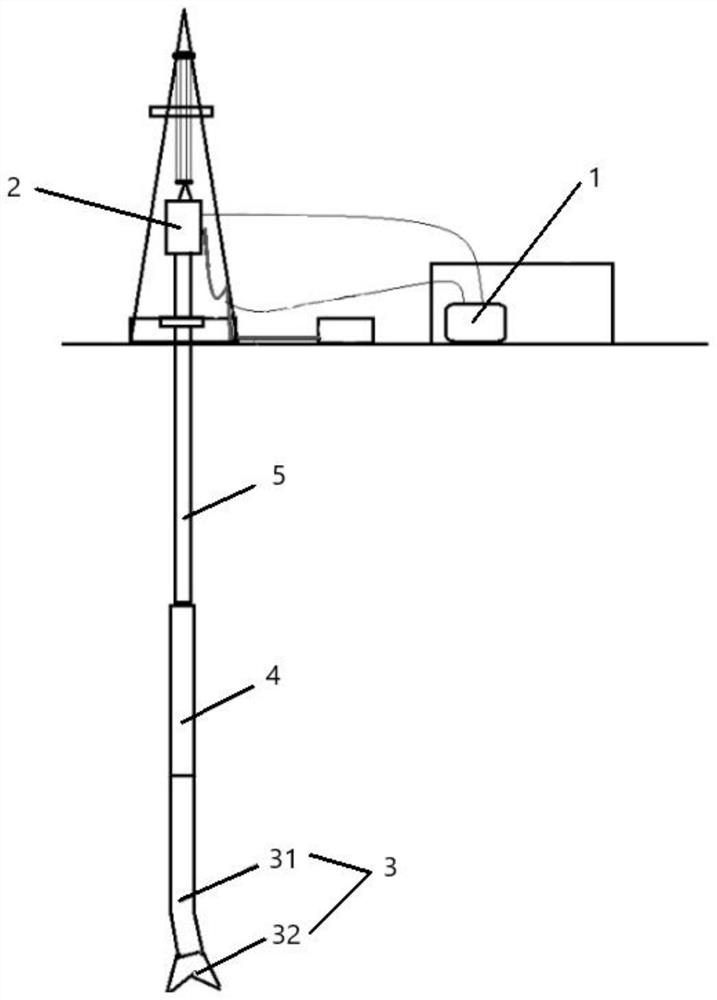

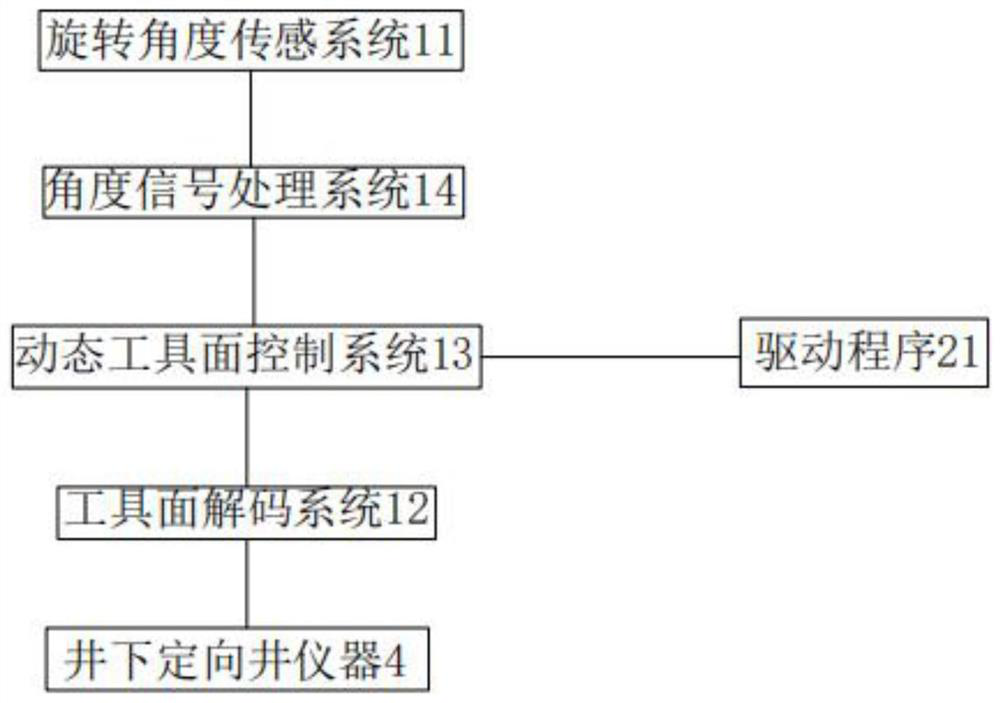

[0038] A rotary steerable drilling system incorporating figure 1 and figure 2 , including an industrial computer 1 , a rotating device 2 , a bottom directional drilling tool 3 , a downhole directional well tool 4 and a drill string 5 .

[0039] The rotating device 2 includes a driver 21, a motor and a rotating machine; the driver 21 receives instructions from the industrial computer 1 to control the motor, the rotating machine is connected to the drill string 5, and the motor drives the rotating machine to drive the drill string 5 to rotate, and the motor is Any one of DC motor, AC motor, variable frequency motor, stepping motor or servo motor, the rotating machine is a turntable or top drive, and the specific structure of the rotating device 2 is the prior art, and will not be described here.

[0040] The upper end of the drill string 5 is connected to the rotary device 2, and the lower end is connected to the bottom directional drilling tool 3. The drill string 5 is the hu...

Embodiment 2

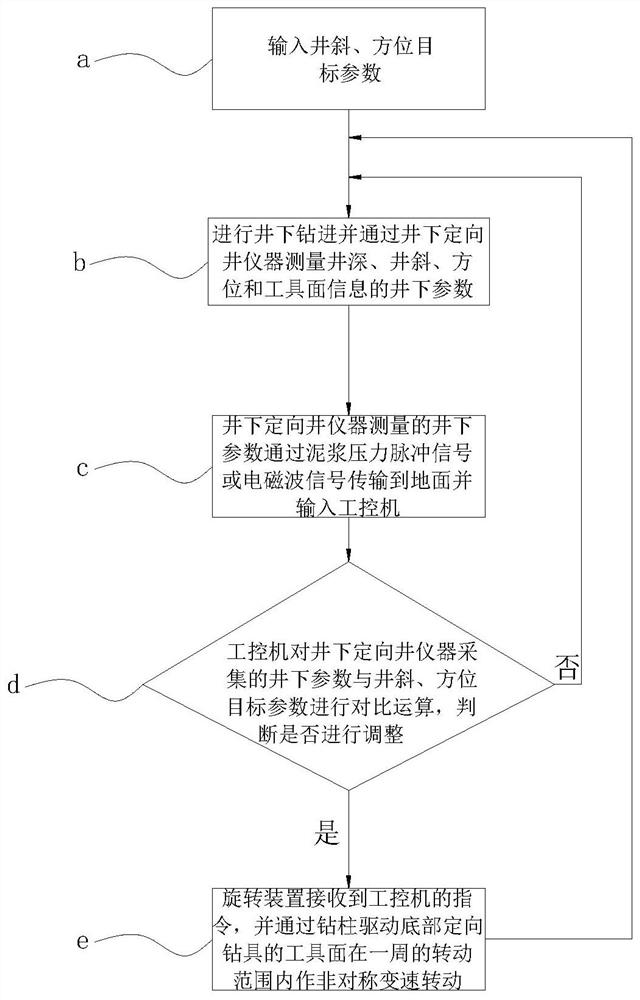

[0051] A control method of the rotary steerable drilling system in Embodiment 1, such as image 3 shown, including the following steps:

[0052] Step a, input well deviation and azimuth target parameters in industrial computer 1;

[0053] Step b, carry out downhole drilling and measure downhole parameters such as well depth, well deviation, azimuth and tool face information through downhole directional well instrument 4;

[0054] Step c, the downhole parameters measured by the downhole directional well tool 4 are transmitted to the ground through the mud pressure pulse signal or electromagnetic wave signal and input into the industrial computer 1;

[0055] Step d, the industrial computer 1 compares the downhole parameters collected by the downhole directional well instrument 4 with the well deviation and azimuth target parameter data, and the specific calculation method of the industrial computer 1 is:

[0056] The high side of the wellbore is the initial phase θ1, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com