Stainless steel motor potting process

A stainless steel and potting technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of motor winding burnout, poor electrical performance, and low motor protection level, and achieves easy operation, simple tooling design, and easy Effects of demolition and secondary use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

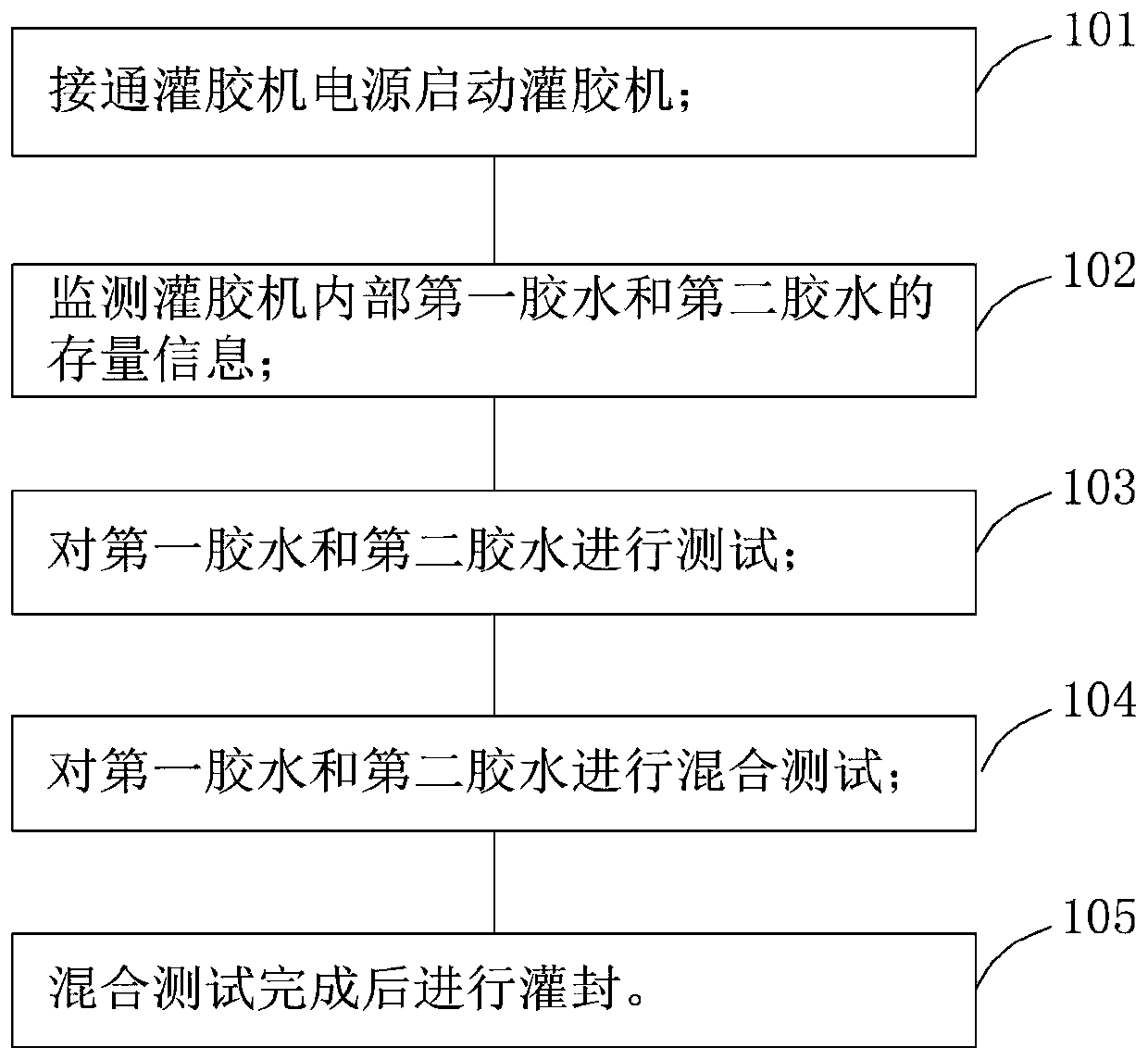

[0031] refer to figure 1 , is a flow chart of the stainless steel motor potting process proposed by the present invention.

[0032] like figure 1 As shown, the stainless steel motor potting process is characterized in that a potting device is used for potting, wherein a capillary stainless steel pipe is arranged inside the shell of the potting device, and a first glue and a second glue are arranged inside the capillary stainless steel pipe, and capillary stainless steel The inside of the steel pipe is provided with a POM material mandrel, and the POM material mandrel is fixed with the shell by a nail-piercing fixing tool, including the following steps:

[0033] Step 101, turn on the power of the glue filling machine and start the glue filling machine;

[0034] Step 102, monitoring the inventory information of the first glue and the second glue inside the glue filling machine;

[0035] Step 103, testing the first glue and the second glue;

[0036] Step 104, performing a mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com