High-toughness carbon nanotube reinforced aluminum-based composite material with non-uniform structure and preparation method thereof

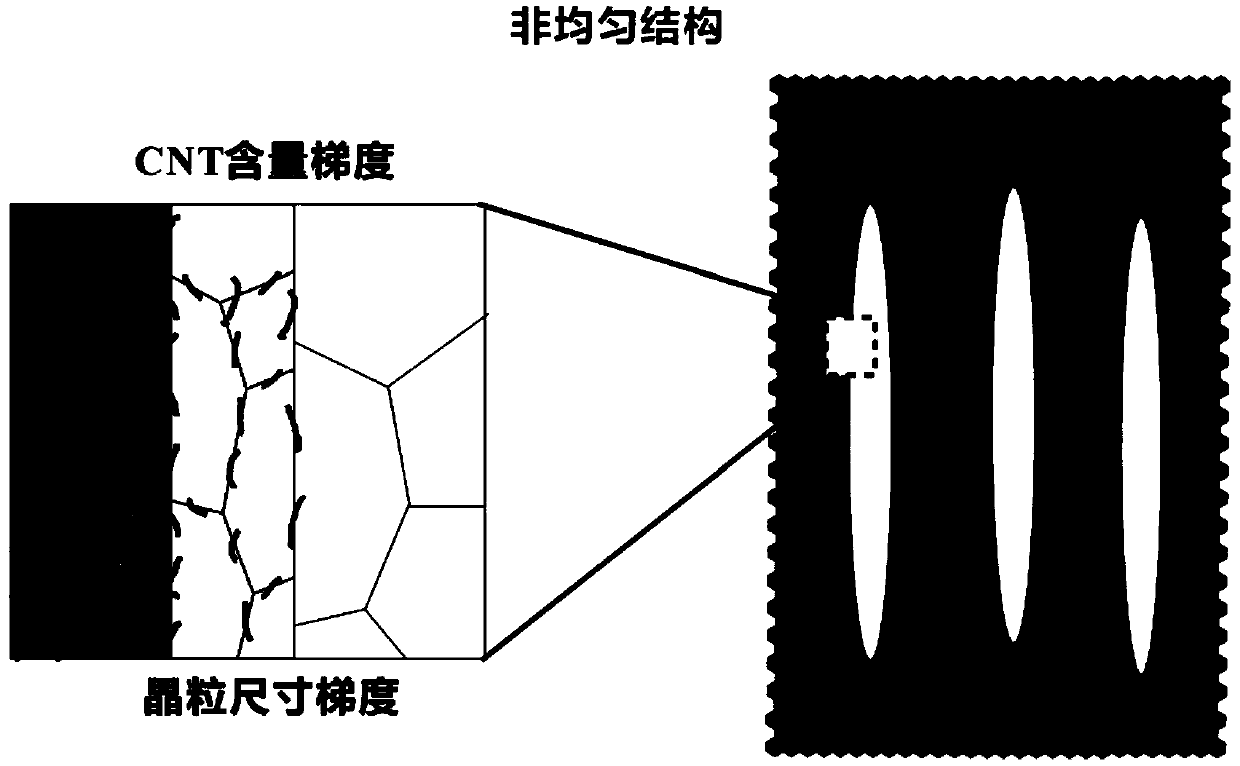

An aluminum composite material and carbon nanotube technology, which is applied in the field of high-strength and tough carbon nanotube-reinforced aluminum composite materials and their preparation, can solve the problems of insignificant improvement in toughness, inability to effectively relax due to stress concentration in brittle regions, and decrease in yield strength, etc. , to achieve the effect of suppressing local strain concentration, good toughness, and compensating for the decrease in yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

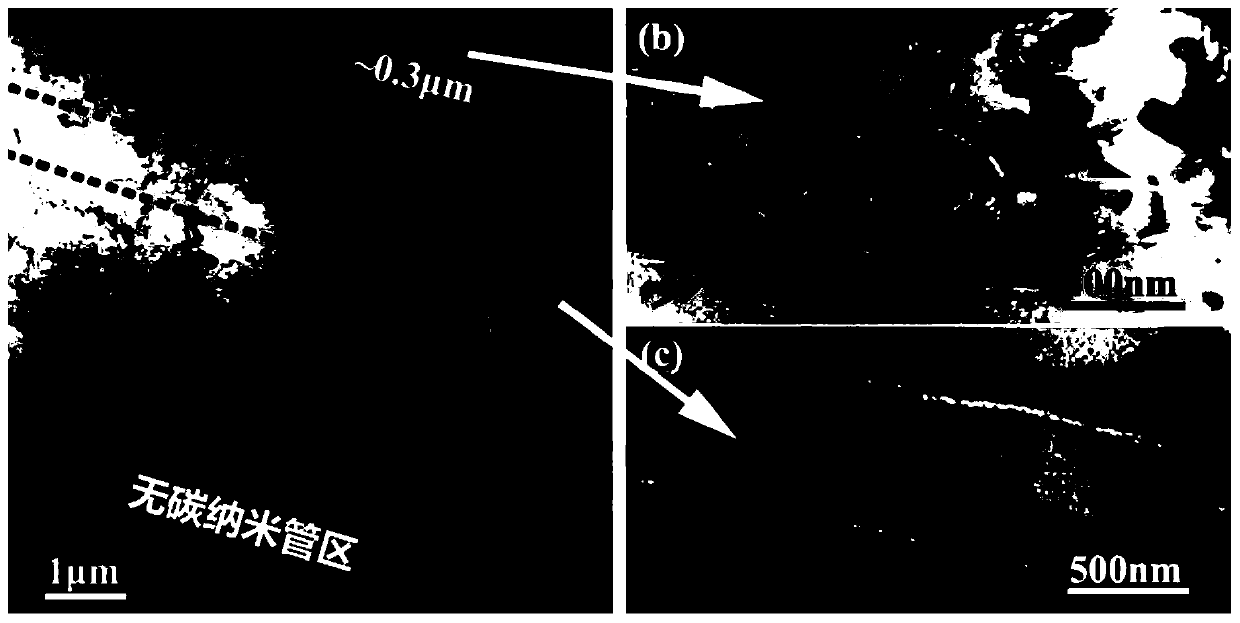

[0032]450g of pre-alloyed 2009Al powder (composed of Al powder, Mg powder, Cu copper element powder) with an average size of 10μm and multi-walled CNT with a content of 4vol.% were evenly mixed and added to the ball mill, and 2wt.% of hard Fatty acid is used as a process control agent, feed argon and cooling water, and ball mill at 350r / min for 2 hours; add 400g of 3vol.%CNT / 2009Al composite powder to the composite material powder, and run at 300r / min for 2 hours ; Add 150 g of pre-alloyed 2009Al powder with an average size of 10 μm to the composite material powder, and ball mill for 0.5 h at a rotational speed of 200 r / min to obtain the final composite material powder. Subsequently, the composite ingot was obtained by cold pressing at 50MPa and vacuum hot pressing at 540°C and 80MPa; the ingot was subjected to hot extrusion with an extrusion ratio of 16:1, and finally a 3vol.%CNT / 2009Al composite with a heterogeneous structure was obtained. Material( figure 2 ).

[0033] T...

Embodiment 2

[0038] 300g of 5083Al alloy powder with an average size of 10 μm and multi-walled CNT with a content of 4vol.% were uniformly mixed and then added to the stirring ball mill, 2wt.% of stearic acid was added as a process control agent, and argon and cooling water were introduced. Ball milling at 400r / min for 2 hours; add 600g of 3vol.%CNT / 5083Al composite powder to the composite powder, and run at 400r / min for 2 hours; add 100g of the average size of 10μm pre-alloy to the composite powder The melted 5083Al powder was ball milled for 0.5h at a rotational speed of 200r / min to obtain the final composite material powder. Subsequently, the composite ingot was obtained by cold pressing at 40MPa and vacuum hot pressing at 500°C and 80MPa; the ingot was subjected to hot extrusion with an extrusion ratio of 16:1, and finally a 3vol.%CNT / 5083Al composite with a heterogeneous structure was obtained. Material. The yield strength of the composite material reaches 500MPa, the tensile strengt...

Embodiment 3

[0042] 363g of 6061Al alloy powder with an average size of 10 μm and multi-walled CNT with a content of 4vol.% were uniformly mixed and added to the stirring ball mill, 2wt.% of stearic acid was added as a process control agent, and argon and cooling water were introduced. Ball milling under 300r / min for 2 hours; Add 91g 3vol.%CNT / 6061Al composite material powder in this composite material powder, move 1.5 hours under 300r / min; Add 182g 1.5vol.%CNT / 6061Al composite material powder in this composite material powder 6061Al composite material powder, run at 300r / min for 1.5 hours; then add 364g of pre-alloyed 6061Al powder with an average size of 10μm to the composite material powder, and ball mill at a speed of 150r / min for 0.5h to obtain the final composite material powder . Subsequently, the composite material ingot was obtained by cold pressing at 40MPa and vacuum hot pressing at 580°C and 100MPa; the ingot was subjected to hot extrusion with an extrusion ratio of 16:1 to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com