A device for measuring the ignition temperature of micro-scale pyrotechnic products

A temperature measurement and pyrotechnic technology, which is applied in the field of micro-scale pyrotechnic ignition temperature measurement devices, can solve the problem that cannot meet the needs of micro-small pyrotechnic measurement, cannot measure the combustion and detonation temperature of pharmaceuticals, and cannot directly contact pyrotechnics. and other problems, to achieve the effect of small size, solving measurement difficulties and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

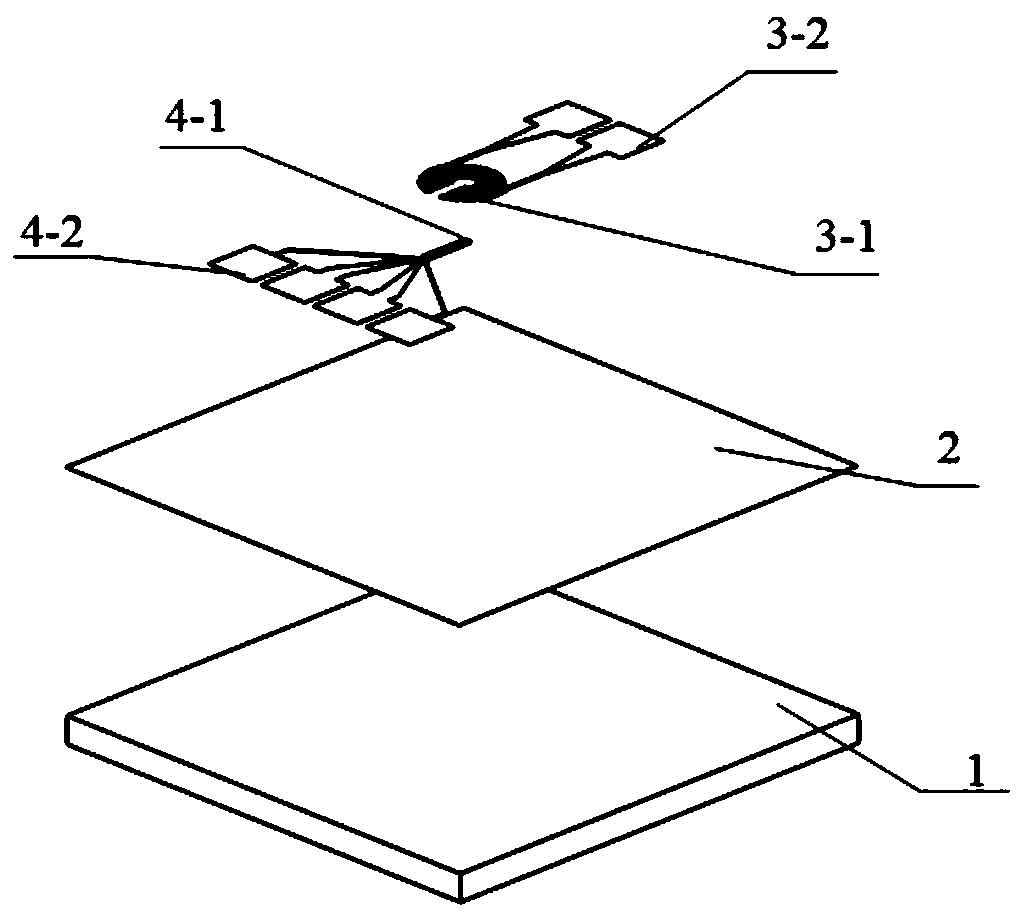

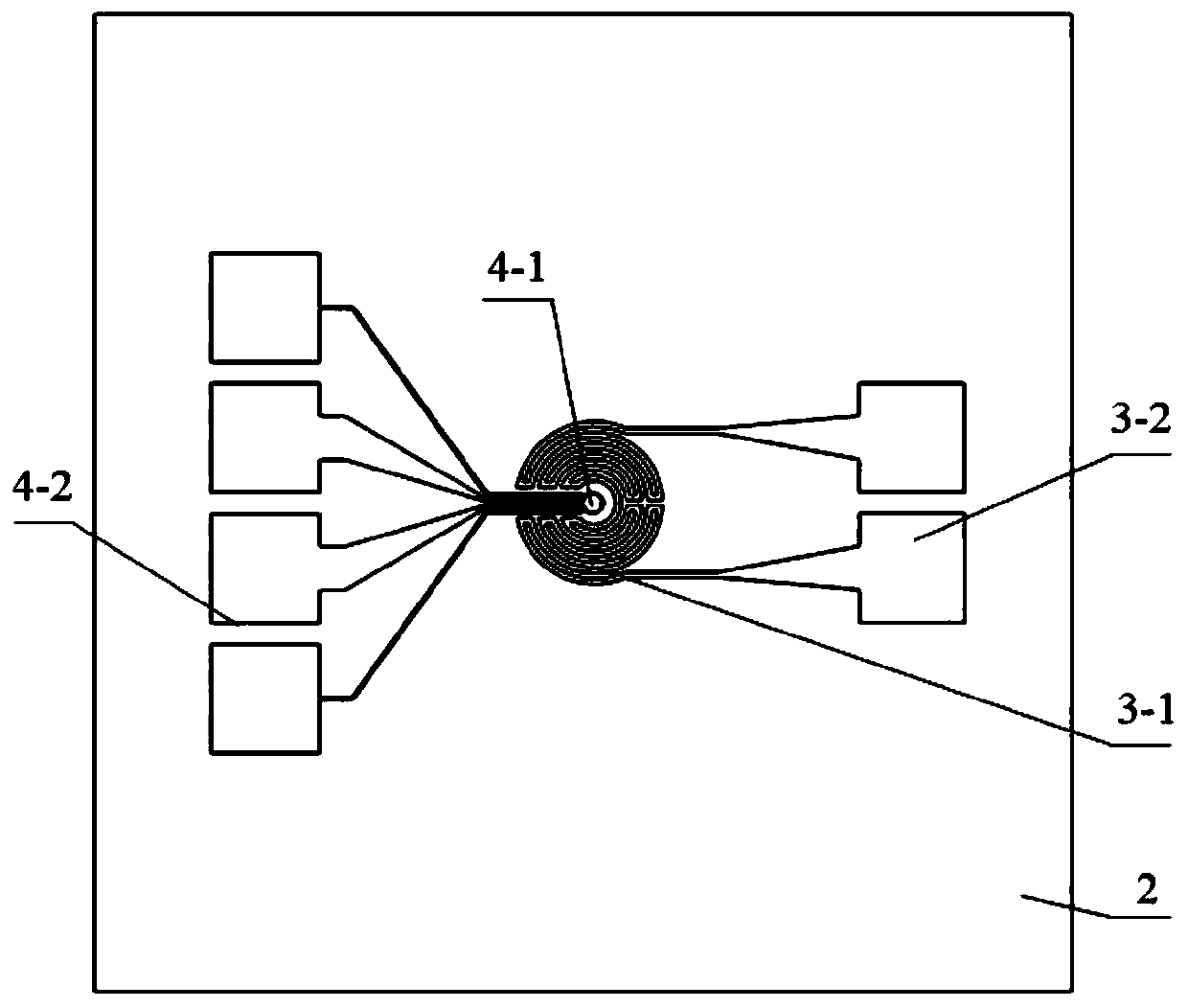

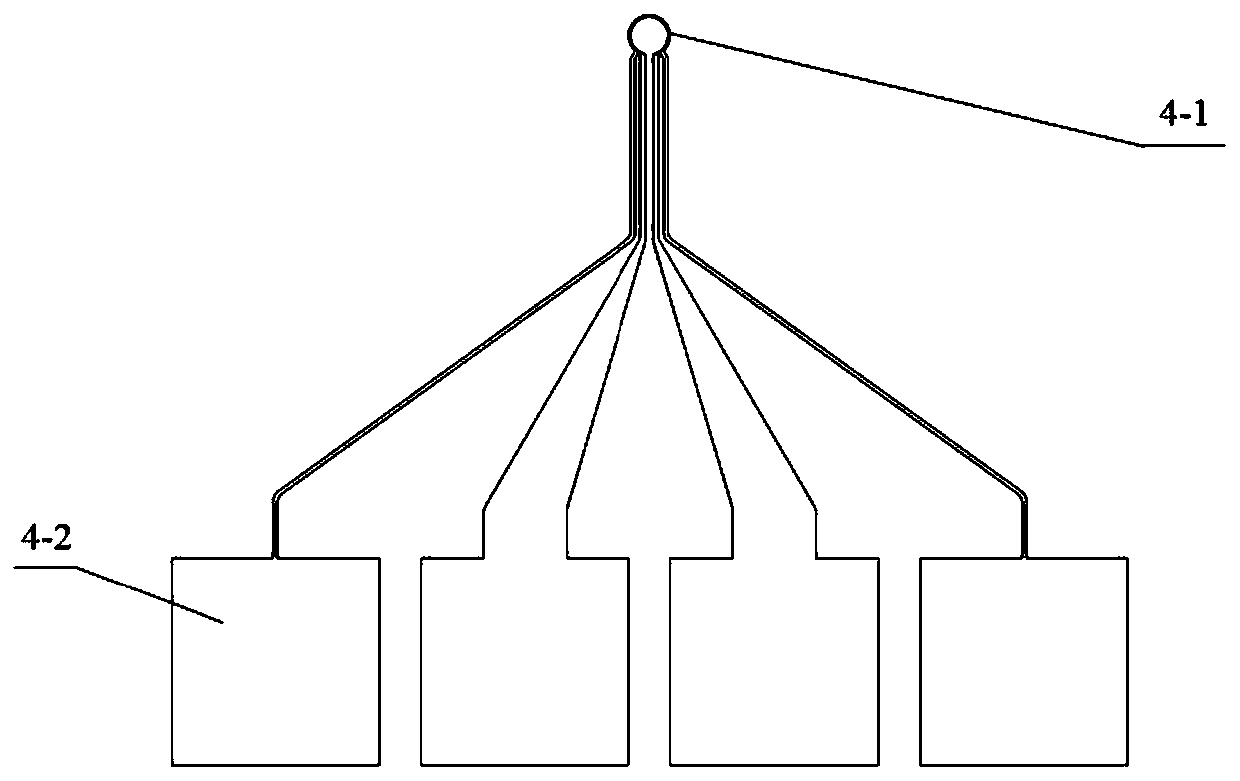

[0019] see figure 1 , figure 2 and image 3 , a micro-scale pyrotechnic ignition temperature sensor, comprising a single crystal silicon substrate 1, a silicon dioxide insulating layer 2 is grown on the single crystal silicon substrate 1, and a platinum microstructure is sputtered on the silicon dioxide insulating layer 2 by MEMS process The transducer 3-1 and the first electrode 3-2 connected to the platinum microstructure transducer 3-1, the first electrode 3-2 serves as the voltage input end of the platinum microstructure transducer 3-1; The MEMS process is used to sputter the platinum temperature sensitive element 4-1 in the middle of the microstructure transducer 3-1, and the platinum temperature sensitive element 4-1 is connected to the second electrode 4-2; the input end and the output of the platinum temperature sensitive element 4-1 Two terminals are respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com