Method for determining amino value by automatic potentiometric titration

A potentiometric titration, amino value technology, applied in the field of analytical chemistry, can solve the problems of slow diazotization rate, low reaction temperature, poor end-point indication sensitivity, etc., to reduce human error, accurate test data, and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

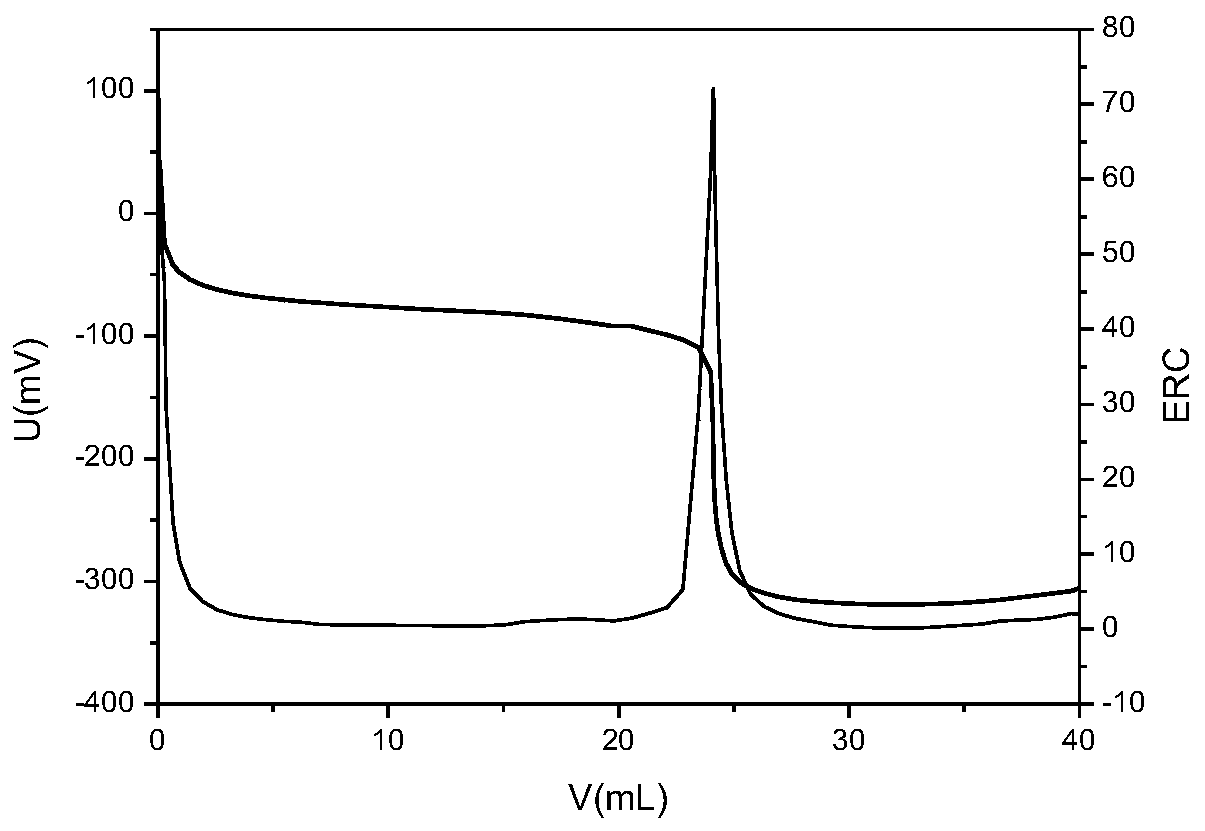

[0029] Embodiment 1. p-nitroaniline amino value determination

[0030] (1) Instrument

[0031] Wantong 888 automatic titrator, Wantong Pt electrode;

[0032] (2) Reagents

[0033] Electrolyte: 100g / L KBr solution; bottom liquid: 20% hydrochloric acid; 40% hydrobromic acid; sodium nitrite standard titration solution: 0.1000mol / L;

[0034] (3) Instrument test parameters

[0035] Titration mode: DET U; Pre-addition volume: 0mL; Pause: 15s; Signal drift: 20Mv / min; Minimum waiting time: 10s; Maximum waiting time: 120s; Minimum increment: 20μL; 50mL; stop equivalence point: 3; liquid volume after equivalence point: 2mL; suction speed: maximum; equivalence point identification standard: 40mV; equivalence point identification: maximum.

[0036] (4) Operation

[0037] Determination of solid samples: Accurately weigh 0.2-0.3g of solid samples (accurate to 0.0001g), add 20mL of 20% hydrochloric acid to ultrasonically dissolve the solids completely, add 10mL of water, then add 10-20m...

Embodiment 2

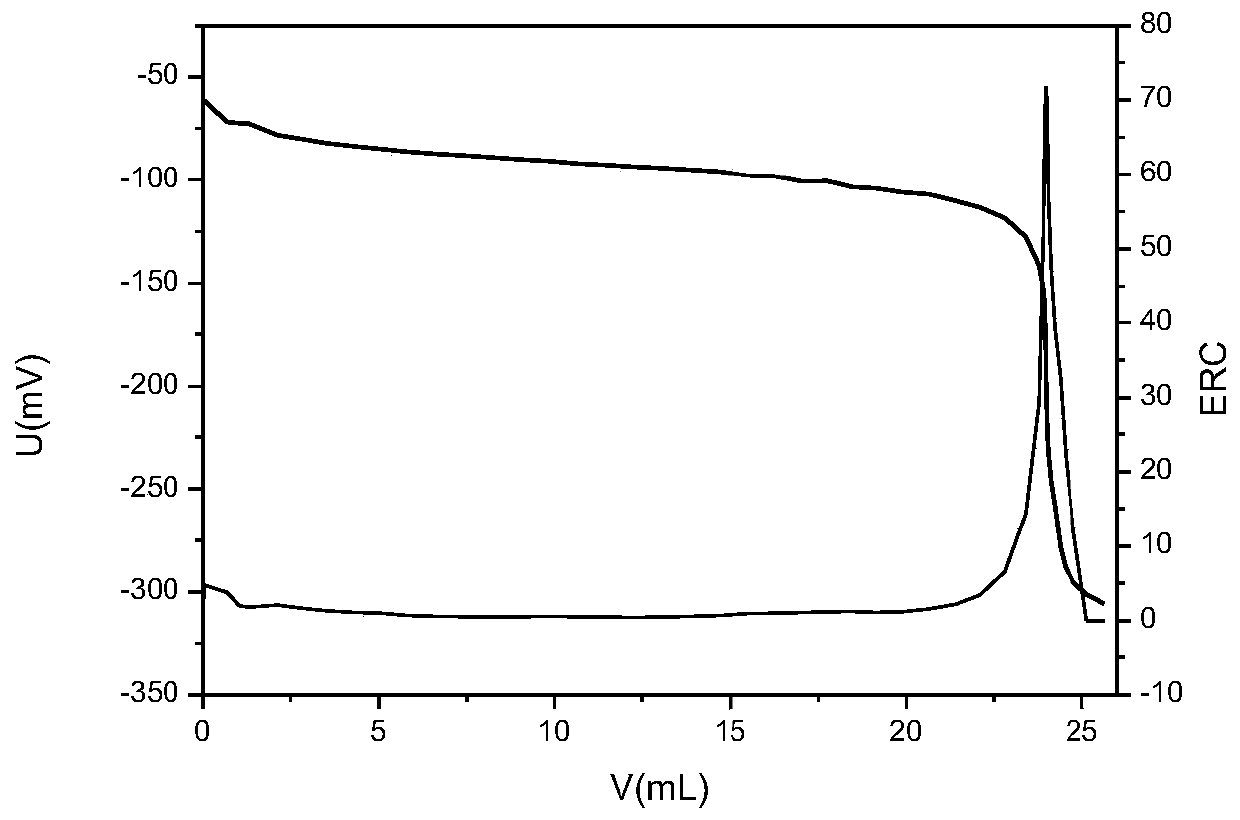

[0047] Embodiment 2.2,5-dichloroaniline amino value determination

[0048] (1) Instrument

[0049] Wantong 888 automatic titrator, Wantong Pt electrode;

[0050] (2) Reagents

[0051] Electrolyte: 100g / L KBr solution; bottom liquid: 20% hydrochloric acid; 40% hydrobromic acid; sodium nitrite standard titration solution: 0.1000mol / L

[0052] (3) Instrument test parameters

[0053] Titration mode: DET U; Pre-addition volume: 0mL; Pause: 15s; Signal drift: 20Mv / min; Minimum waiting time: 10s; Maximum waiting time: 120s; Minimum increment: 20μL; 50mL; stop equivalence point: 3; liquid volume after equivalence point: 2mL; suction speed: maximum; equivalence point identification standard: 40mV; equivalence point identification: maximum.

[0054] (4) Operation

[0055] Solid sample determination: Accurately weigh 0.2-0.3g of solid sample (accurate to 0.0001g), add 50mL 20% hydrochloric acid ultrasonically to dissolve the solid completely, then add 5-10mL hydrobromic acid, 10mL KBr...

Embodiment 3

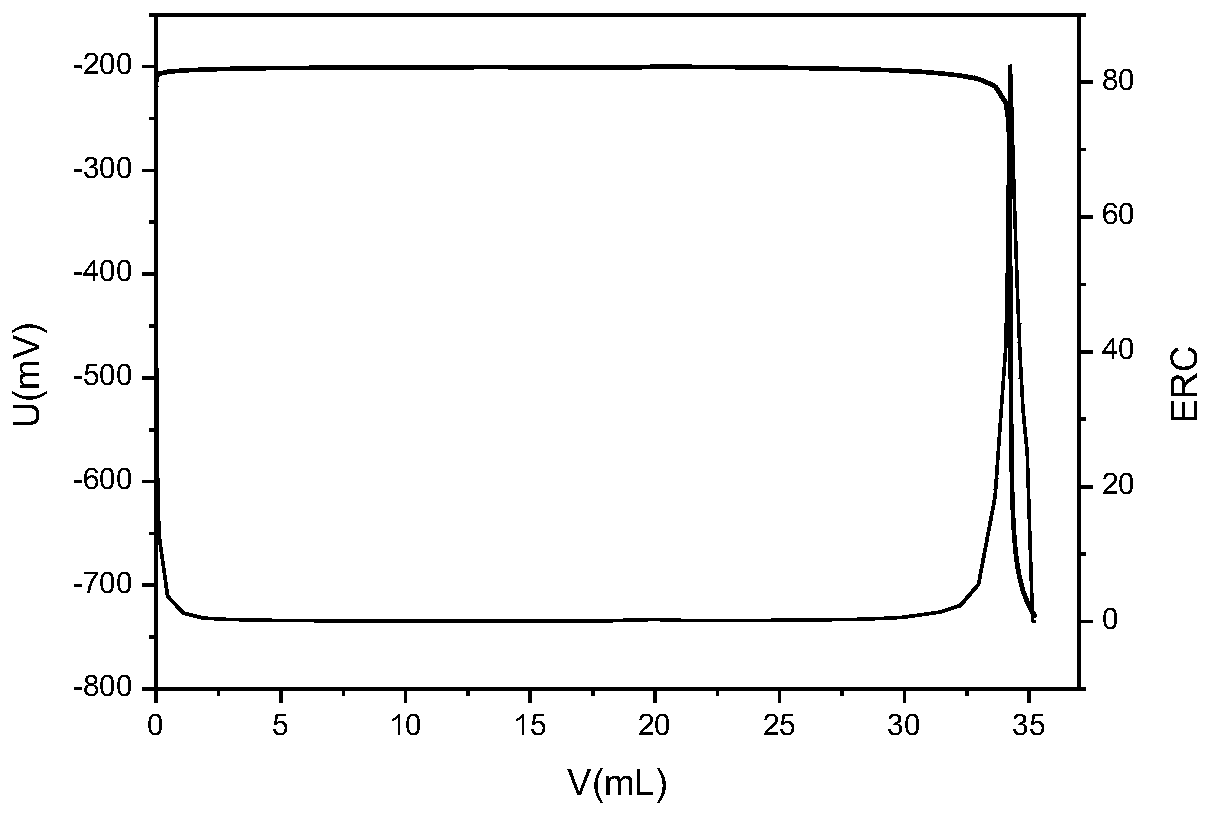

[0065] Example 3 Determination of the amino value of 3,3'-dichloro-4,4'-diaminodiphenylmethane

[0066] (1) Instrument

[0067] Wantong 888 automatic titrator, Wantong Pt electrode;

[0068] (2) Reagents

[0069] Electrolyte: 100g / L KBr solution; bottom liquid: 20% hydrochloric acid; 40% hydrobromic acid; sodium nitrite standard titration solution: 0.1000mol / L

[0070] (3) Instrument test parameters

[0071] Titration mode: DET U; Pre-addition volume: 0mL; Pause: 15s; Signal drift: 20Mv / min; Minimum waiting time: 10s; Maximum waiting time: 120s; Minimum increment: 20μL; 50mL; stop equivalence point: 3; liquid volume after equivalence point: 2mL; suction speed: maximum; equivalence point identification standard: 40mV; equivalence point identification: maximum.

[0072] (4) Operation

[0073] Solid sample determination: Accurately weigh 0.2-0.3g of solid sample (accurate to 0.0001g), add 30mL of 20% hydrochloric acid and ultrasonically dissolve the solid completely, then ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com