Semiconductor device and forming method thereof

A semiconductor and device technology, applied in the field of semiconductor devices and their formation, can solve the problems of semiconductor device performance degradation, etc., and achieve the effects of improving uniformity, improving performance, and controlling fin size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

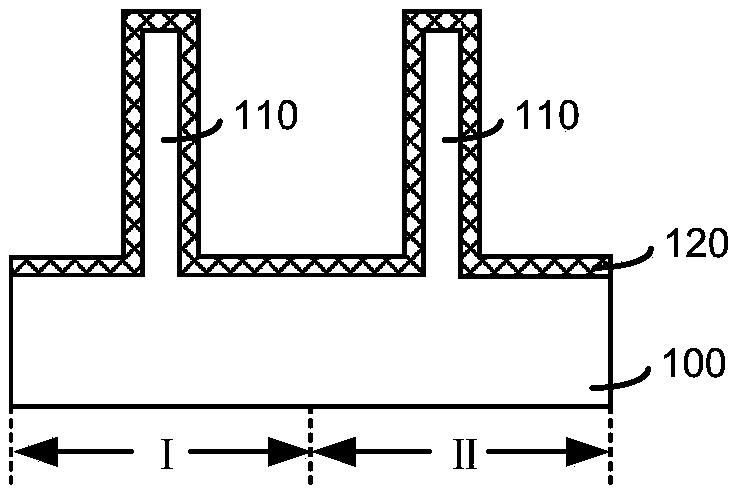

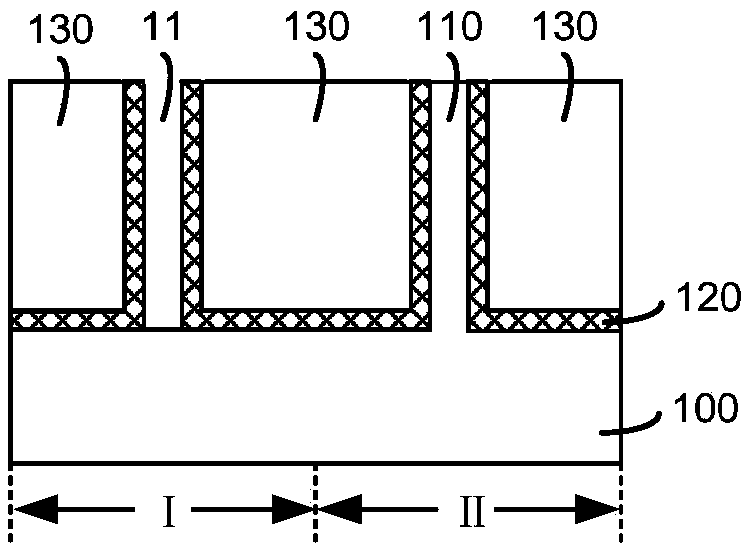

[0045] Please refer to figure 1 , a fin portion 110 is formed on the semiconductor substrate 100 , and a first source doped film 120 is formed on the surface of the semiconductor substrate 100 and the fin portion 110 .

[0046] The semiconductor substrate 100 serves as a process basis for forming semiconductor devices. The material of the semiconductor substrate 100 is polysilicon. In the embodiment of the present invention, the semiconductor substrate 100 also contains other structures, such as: metal plugs, metal connection layers, dielectric layers and other structures, or other semiconductor devices composed of these structures, which are not described here. Specific restrictions.

[0047] In the embodiment of the present invention, the semiconductor substrate 100 includes a first region I and a second region II. The two regions are doped with different types of ions. In the embodiment of the present invention, the first region I and the second region II are respectiv...

no. 2 example

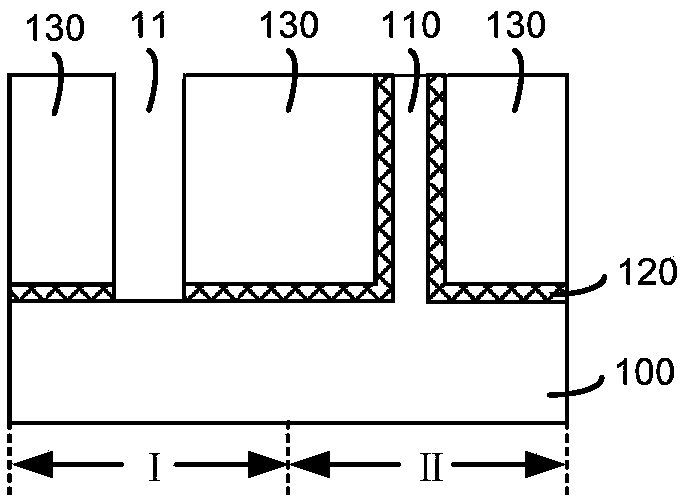

[0099] Please refer to Figure 6-Figure 9 Compared with the first embodiment, the method for forming a semiconductor device according to the second embodiment of the present invention differs in that when the fin above the first region I is removed to form the first groove, the second region is also removed at the same time Ⅱ above the fin to form the second groove. Subsequently, a second replacement fin also needs to be formed in the second groove. Other processes are consistent with the first embodiment.

[0100] Please refer to Figure 6 , the fins above the first region I and the second region II are removed, and the first groove 21 and the second groove 22 are correspondingly formed respectively.

[0101] The formation steps, functions and material selection of the semiconductor substrate 200, the first source-doped thin film 220 and the interlayer dielectric layer 230, as well as the process method for forming the first groove 21 are all consistent with the first embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com