Cell microcarrier separating device

A technology of cell microcarrier and separation device, which is applied in the field of cell microcarrier separation device, which can solve the problems that antibody filtration and clarification methods cannot be used, separation filter membranes are clogged, and centrifugation methods cannot achieve ideal separation effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

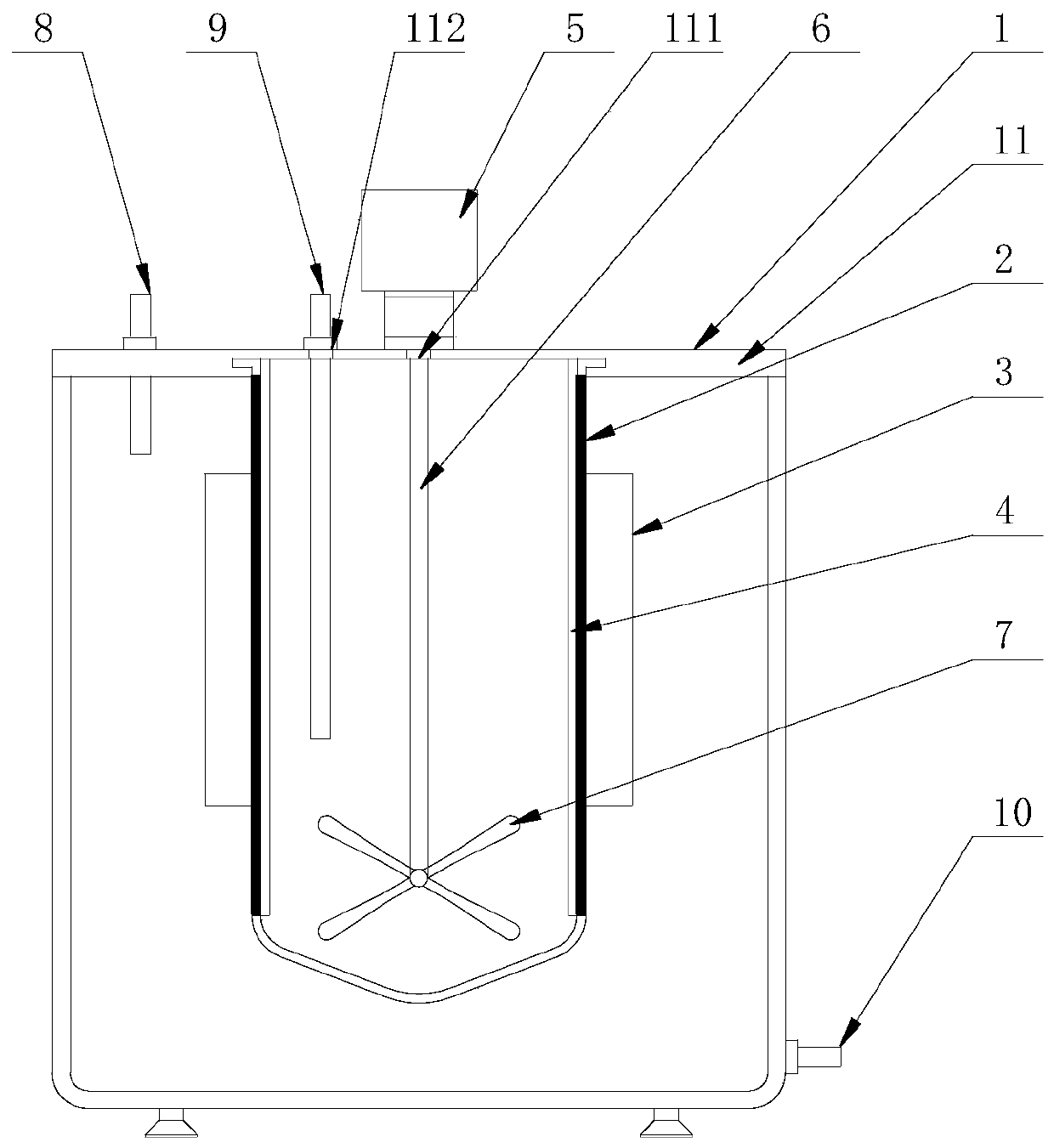

[0055] This embodiment describes a microcarrier separation device of the present invention with reference to the accompanying drawings.

[0056] Such as figure 1 As shown, the separation device includes a tank body 1, a filter 2, a stirring system and a liquid inlet and outlet. The tank body 1 can contain the microcarrier cell mixture to be separated. The tank body 1 has an end cover 11 which can seal the tank body 1 . The tank body 1 is made of stainless steel.

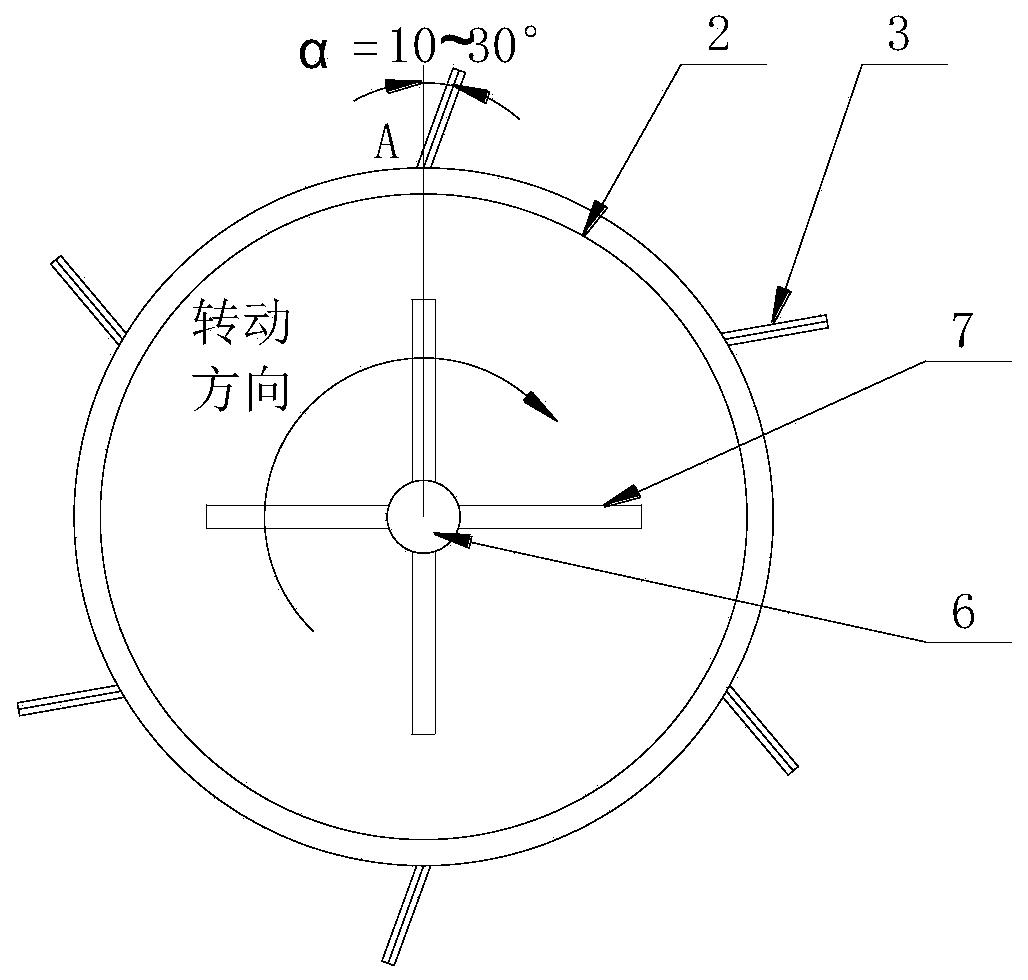

[0057]The filter 2 comprises a baffle support 3 and a vessel frame structure, optionally also comprising a first filter membrane and a second filter membrane. The container frame structure includes a structure forming the upper opening of the container, a filter membrane fixing member 4 formed around the container for fixing the filter membrane connected with the structure forming the upper opening of the container, and a bottom container connected with the fixing member. The material of the retainer supporting m...

Embodiment 2

[0062] This embodiment describes the operation process of using the microcarrier separation device in Embodiment 1 to separate microcarriers and cells with reference to the accompanying drawings.

[0063] When the separation device is working, the microcarrier cell mixture and separation enzyme liquid to be separated are firstly added through the liquid inlet 8 and mixed thoroughly. A filter membrane (with a pore size of 50-70 μm) is placed in both the filter membrane fixing part 4 and the stopper support part 3 of the filter 2, and the filter 2 is fixed on the end cap 11. Cover the end cover 11, turn on the stirring system, the motor 5 drives the stirring paddle 7 to rotate rapidly through the stirring shaft 6, and forms a vortex flow field in the liquid. At this time, the microcarriers and cells outside the filter 2 all flow towards the center of the vortex, and when they flow to the first filter membrane on the filter membrane holder 4 of the filter 2, the cells can normall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com