A Membrane Electrode with Ultralow Oxygen Mass Transfer Resistance

A mass transfer resistance, membrane electrode technology, applied in battery electrodes, circuits, fuel cells, etc., can solve the problems of battery mass transfer polarization loss, affecting the mass transfer resistance of the catalytic layer, etc., to achieve optimized Nafion distribution, reasonable Nafion distribution, The effect of reducing the density of the unit distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

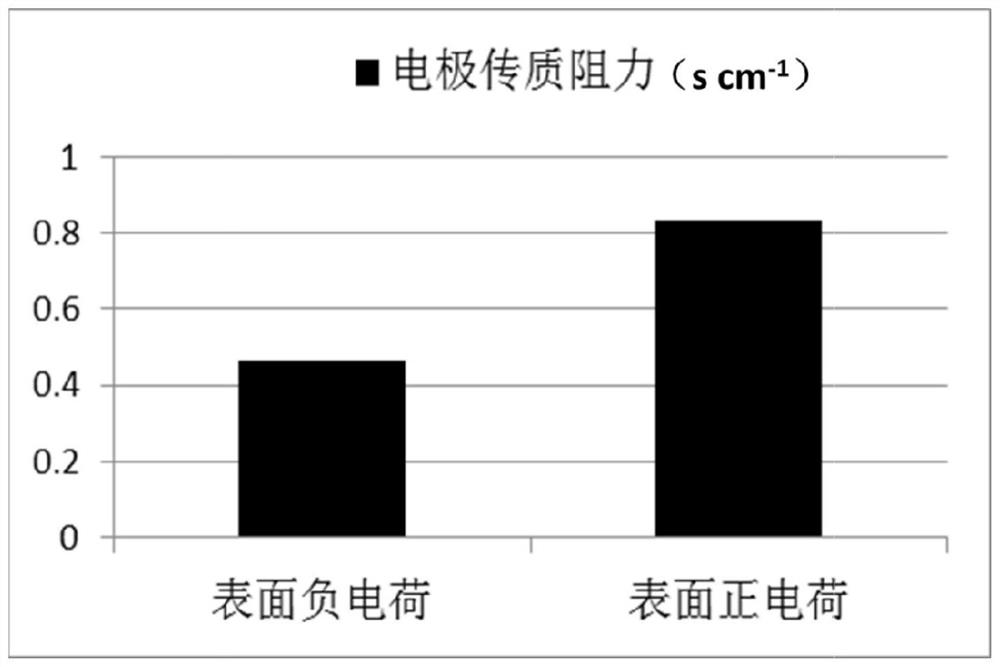

[0034] 1. Preparation of materials. Mix XC-72 carbon with concentrated sulfuric acid (mass ratio 1:3), react at 180°C for 24 hours, and load negative charges to obtain negatively charged modified carbon supports. Disperse 2g of negatively charged modified carbon carrier in 200ml of aqueous solution, and dissolve 2.5g of chloroplatinic acid hexahydrate. After sonicating for 30 minutes, add 0.5mol L dropwise -1 A total of 6ml of sodium borohydride solution was reduced to platinum nanoparticles to obtain a negatively charged platinum-carbon catalyst.

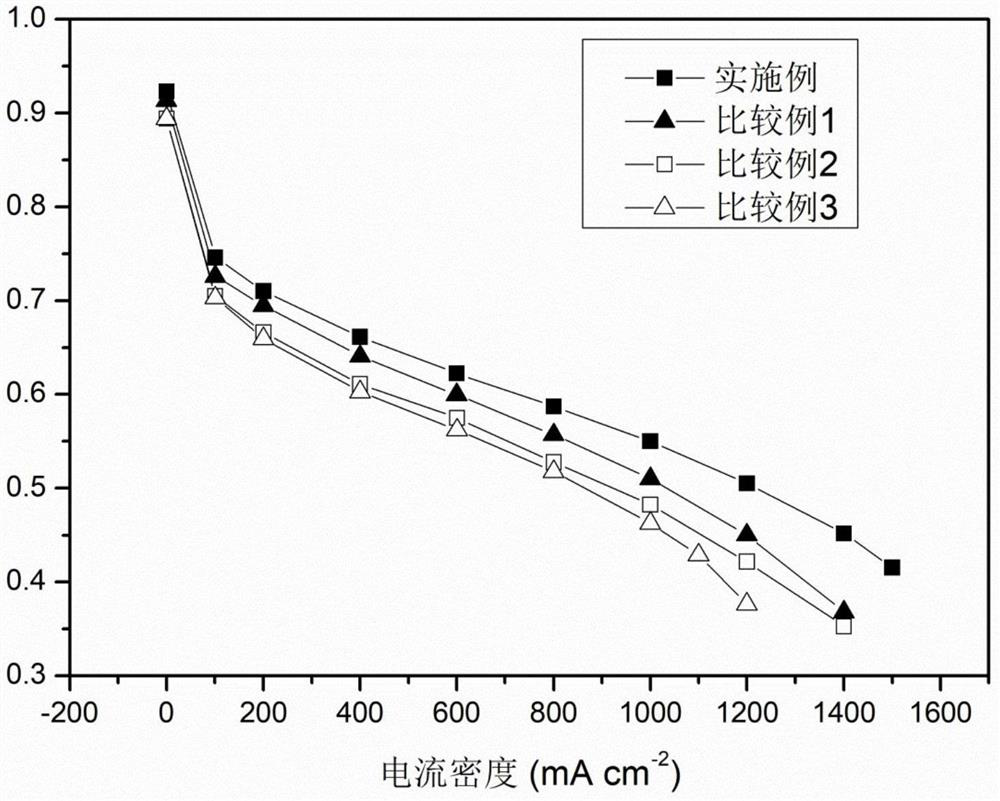

[0035] 2. Preparation of membrane electrodes. Add 0.062g negatively charged platinum-carbon catalyst and 0.15g concentration of 20% commercial ion resin Nafion solution to 15ml isopropanol and water mixed solvent (volume ratio 3:1), and further add 0.031g negatively charged modified The carbon carrier, after ball milling the mixed slurry for 24 hours, was sprayed on the proton membrane as the cathode.

Embodiment 1~3

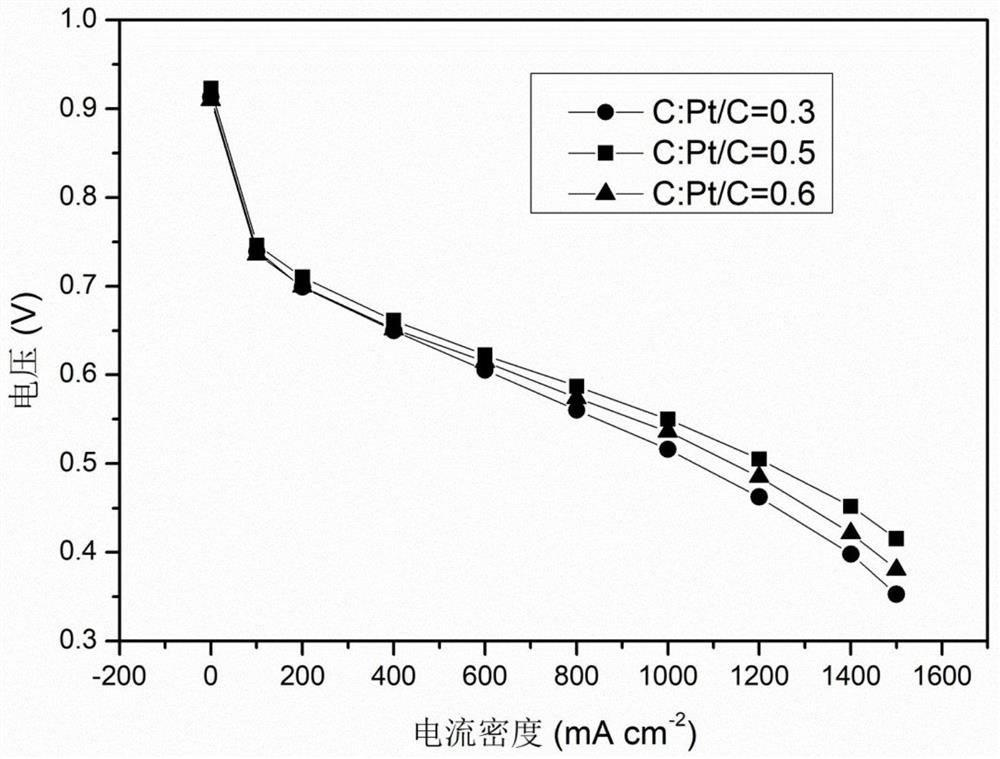

[0041] In order to optimize the consumption of the negatively charged carbon carrier, the present invention has adopted three embodiments altogether, the platinum carbon catalyst (catalyst platinum loading about 50 %) are respectively 0.3:1, 0.5:1, and 0.6:1 in mass ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com