Radio frequency interconnection method for TR assembly and antenna array plane

An antenna array and component technology, applied in the microwave field, can solve problems such as inconvenient disassembly, testing and maintenance, large radio frequency interconnection size, and difficult KK positioning, etc., to achieve the effect of ensuring long-term reliability, good air tightness, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

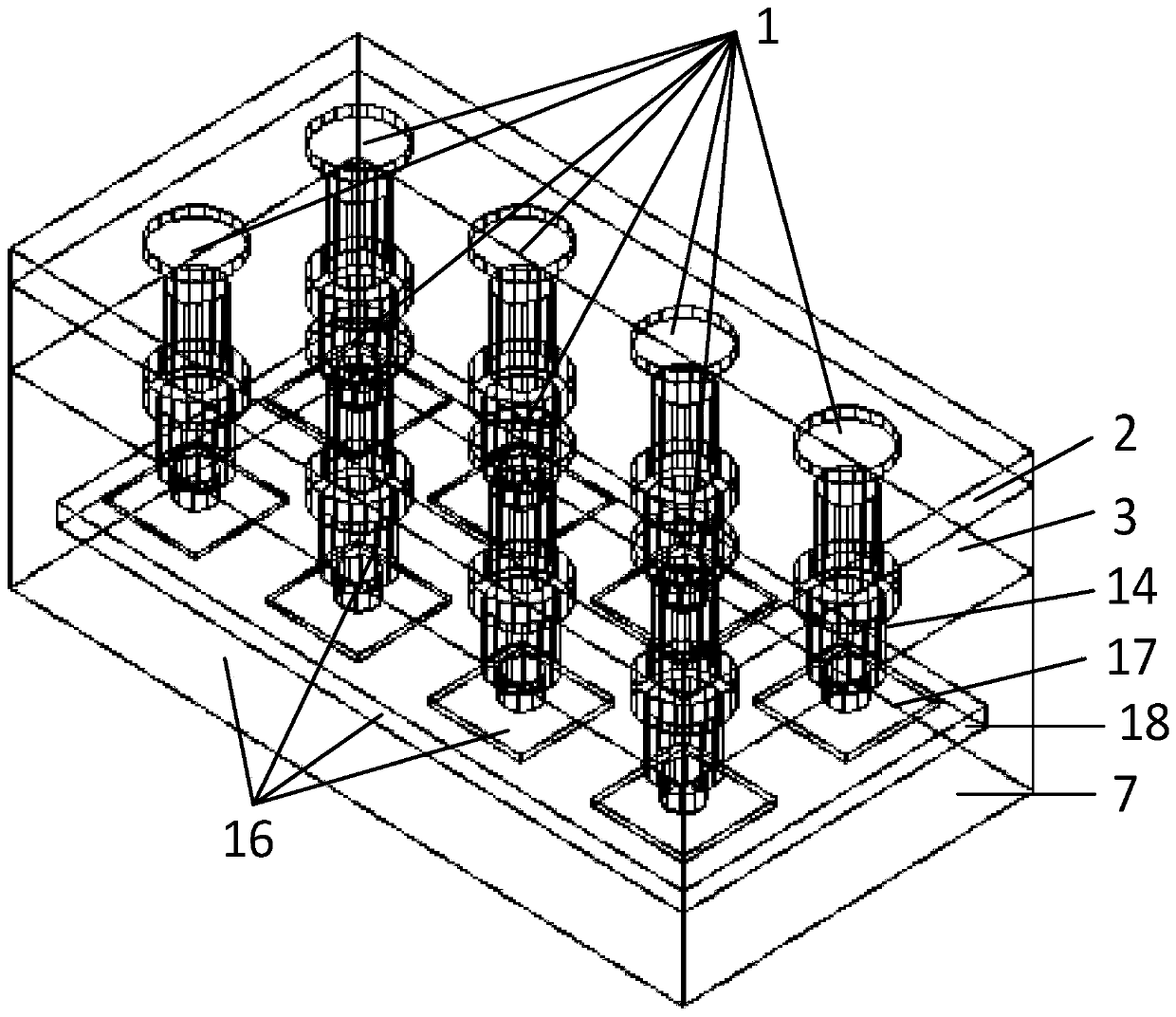

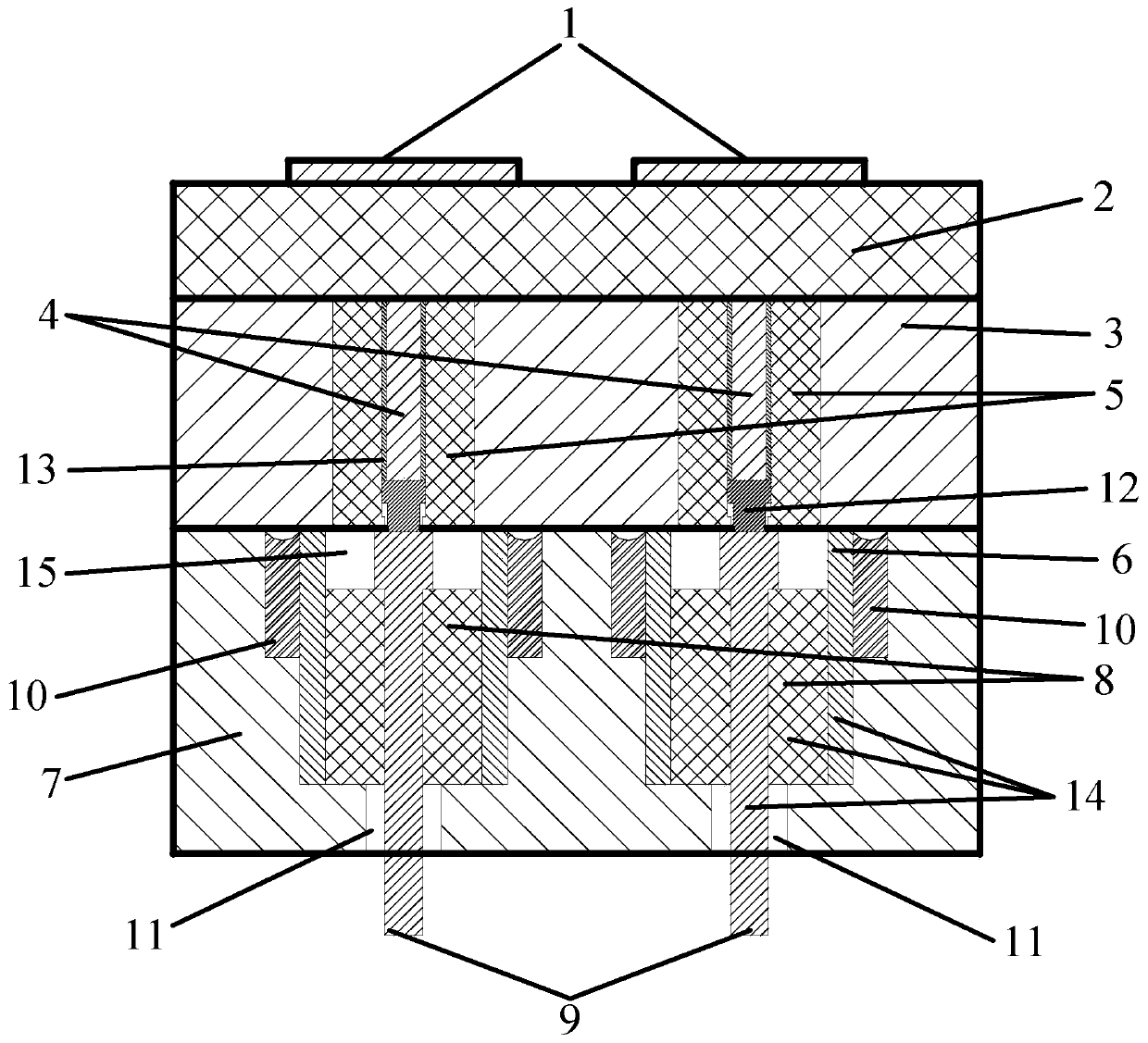

[0014] refer to figure 1 , figure 2 . According to the present invention, the patch antenna 1 arranged and distributed in a linear array is fixed on the antenna-carrying medium substrate 2, and the antenna-carrying medium substrate 2 presses the outer conductor 7 of the TR component structural member tightly through the button metal substrate 3; vertically corresponds to the patch antenna 1 The polymer-based composite dielectric tube 5 on the lower front passes through the button metal substrate 3, and is closely attached to the end face of the radio frequency connection insulator 14; the insulator solder 10 is used to integrally sinter the outer conductor 7 of the structural part of the TR assembly The radio frequency connection insulator 14, corresponding to the polymer-based composite dielectric tube 5, is assembled in the stepped hole of the outer conductor 7 of the TR component structure; the button inner core 4 passes through the button inner core sleeve 13, and is tig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com