Special material for heatproof polyethylene steel skeleton reinforced composite pipeline, and preparation method thereof

A technology of heat-resistant polyethylene and special materials for pipes, applied in the field of materials, can solve the problems of poor appearance gloss, low tensile strength, and high viscosity of HDPE materials, and achieve good surface gloss, small thermal shrinkage coefficient, and good resistance The effect of cracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Formula composition in parts by weight:

[0031] Polyethylene 80 kg

[0032] Filling 12 kg

[0033] Chain extender 3 kg

[0034] Flow modifier 2.5 kg

[0035] Antioxidant 0.3 kg

[0036] UV absorber 0.2 kg

[0037] Crosslinker 2 kg

[0038] 2) The preparation method is carried out according to the following steps:

[0039] (1) Add 12kg of alumina and 1 wt% silane coupling agent KH560 into the high mixer, keep the rotation speed at 2000 rpm, and stir at high speed for 30min to obtain the filler according to the present invention;

[0040] (2) Put 80 kg of polyethylene dried to remove moisture and 15 kg of filler obtained in step (1) into a high-speed mixer to mix, keep the rotating speed at 2000 rpm, and stir at high speed for 30 min;

[0041] (3) 3 kg of chain extender, 2.5 kg of fluoropolymer auxiliary agent PPA (CHY-F5000), 0.3 kg of antioxidant (by antioxidant 1010 0.15 kg, 0.15 kg of phosphite), 0.2 kg of UV531, and 2 kg of crosslinking agent were added t...

Embodiment 2

[0045] 1) Formula composition in parts by weight:

[0046] Polyethylene 80 kg

[0047] Filling 10 kg

[0048] Chain extender 3 kg

[0049] Flow modifier 3 kg

[0050] Antioxidant 0.6 kg

[0051] UV absorber 0.4 kg

[0052] Crosslinker 3 kg

[0053] 2) preparation method, carry out according to the following steps:

[0054] (1) Add 5kg of alumina, 5kg of magnesium oxide and 1 wt% of silane coupling agent KH560 into the high mixer, keep the rotation speed at 2000 rpm, and stir at high speed for 30min to obtain the filler according to the present invention;

[0055] (2) Put 80 kg of polyethylene dried to remove moisture and 8 kg of filler obtained in step (1) into a high-speed mixer to mix, keep the rotating speed at 2000 rpm, and stir at high speed for 30 min;

[0056] (3) 3 kg of chain extender obtained in step (2) after drying, 3 kg of flow modifier (2 kg of fluoropolymer additive PPA (CHY-F5000), 1 kg of silicone powder), antioxidant Add 0.6 kg (consisting of 0.4 kg of ...

Embodiment 3

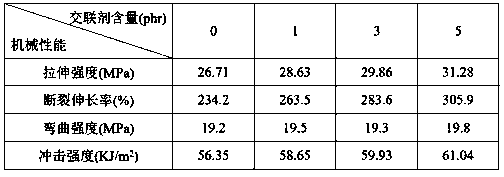

[0060] Add 8.5 kg of polyethylene, 0.8 kg of alumina, 0.2 kg of magnesium oxide, 0.3 kg of chain extender, 0.1 kg of flow modifier, 0.06 kg of antioxidant, 0.04 kg of ultraviolet absorber, and crosslinking agent in an amount of 1 phr , 3 phr, and 5phr were mixed evenly, and melted and granulated in a twin-screw extruder. ℃, 170 ℃, screw speed 200 r / min, feeding speed 20 r / min, injection molding machine temperature 200 ℃, 210 ℃, 198 ℃, respectively. The samples obtained by injection molding were subjected to tensile (GB / T1040.2-2006) and impact (GB / T1943-2008) performance tests, and the results are shown in Table 2.

[0061] With the increase of the number of cross-linking agents, the impact strength of polyethylene is significantly improved, and the tensile strength is also significantly improved, which is the formation of a cross-linked network structure in the polymer material.

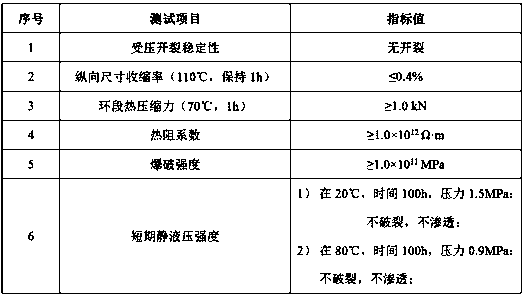

[0062] Table 1 is the performance index value of the heat-resistant polyethylene pipe prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com