Preparation method of starch gel food additive

A technology of gel food and additives, which is applied in the direction of food ingredients as gelling agent, food freezing, food ingredients, etc. It can solve the problems of poor quality of finished products, low water solubility, difficulty in raw starch, etc., and achieve good gel properties, water solubility Good properties, enhanced gel and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

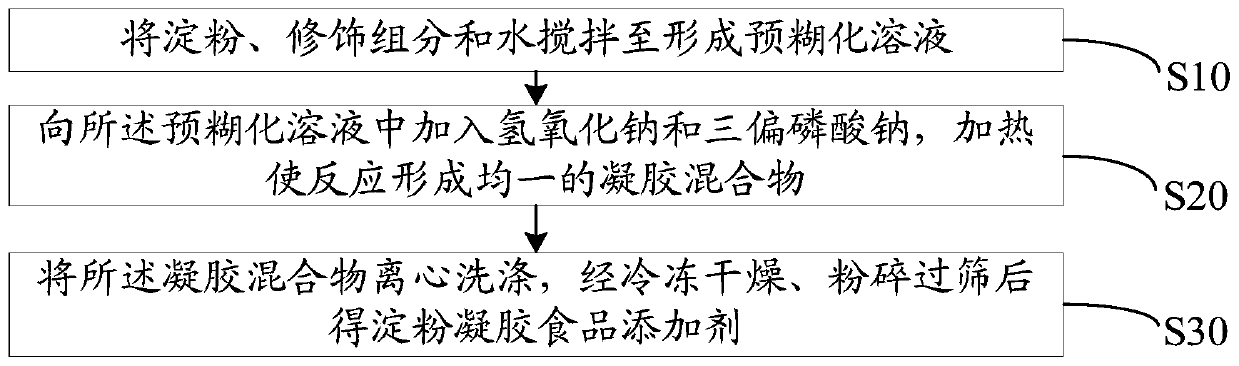

[0029] refer to figure 1 , the preparation method of described starch gel food additive comprises the following steps:

[0030] Step S10, stirring the starch, modification components and water until a pregelatinization solution is formed. Wherein, the modification component is zein or chitosan.

[0031] In this embodiment, starch and modified components are added to water, and stirred continuously to form a pregelatinized solution. The water is deionized water, and the starch is cornstarch. In specific implementation, there are two options for the modification component, that is, it can be zein or chitosan, both of which are edible food-grade raw materials, safe and non-toxic, and can Interact with starch molecules to improve the performance of starch microgels. When choosing to add zein, the mass ratio of starch and zein can be 10: (0.25~1), preferably 10:0.25; when choosing to add chitosan, the mass ratio of starch and chitosan can be It is 10:(1-5), preferably 10:3.

...

Embodiment 1

[0041] Weigh 10g of cornstarch and 0.25g of zein in 100ml of deionized water, heat and stir at 40°C for 30min to obtain a starch pregelatinization solution containing zein, then add 1g of sodium hydroxide and 1g of sodium trimetaphosphate, heated to 40°C, and reacted for 2 hours to obtain a uniform starch gel mixture. The prepared starch gel mixture is centrifuged, washed with deionized water and ethanol, freeze-dried, pulverized, and passed through a 100-mesh sieve to obtain the starch gel food additive.

Embodiment 2

[0043] Weigh 10g of cornstarch and 0.5g of zein in 100ml of deionized water, heat and stir at 40°C for 30min to obtain a starch pregelatinization solution containing zein, then add 1g of sodium hydroxide and 1g of Sodium trimetaphosphate, heated to 40°C, reacted for 2 hours to obtain a uniform starch gel mixture. The prepared starch gel mixture is centrifuged, washed with deionized water and ethanol, freeze-dried, pulverized, and passed through a 100-mesh sieve to obtain the starch gel food additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com