Separation device for waste vehicle-mounted lithium power battery electrode slices and separation method

A power battery and separation device technology, which is applied in the field of separation devices for waste vehicle lithium power battery electrodes, can solve problems such as low application value, low recovery rate, and environmental pollution, and achieve simplified advanced treatment processes and improved recycling rates. , avoid the effect of complex ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

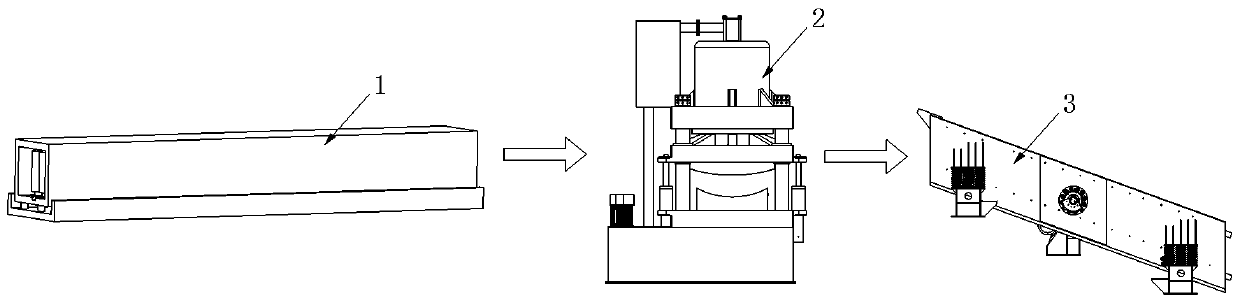

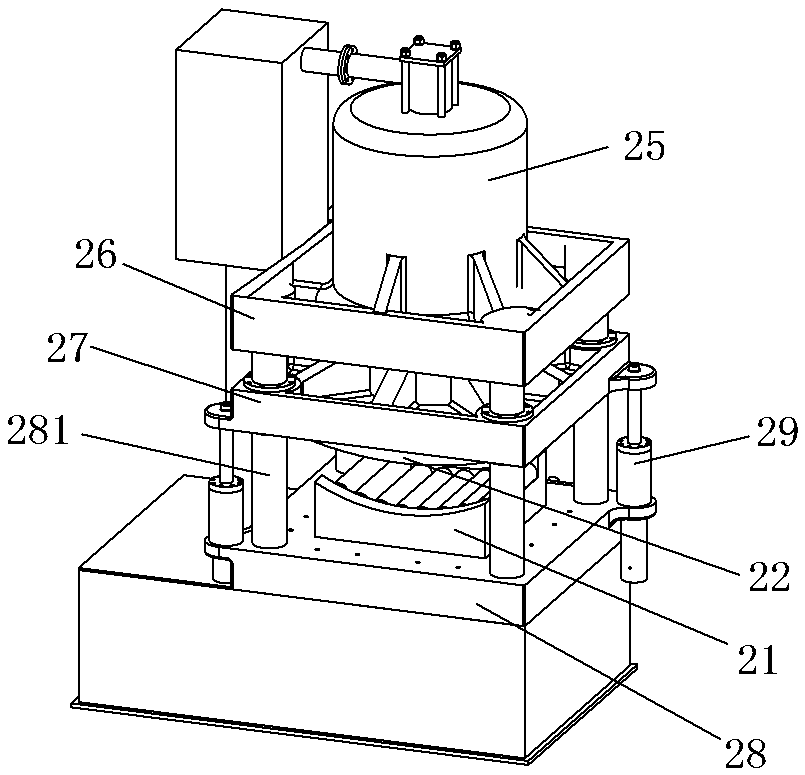

[0027] Such as figure 1 The shown separation device for the electrode sheets of waste vehicle-mounted lithium power batteries includes a thermal separation mechanism 1, a stamping friction separation mechanism 2, and a vibrating screening mechanism 3 arranged sequentially in an assembly line. The electrode sheet 4 passes through the thermal separation mechanism 1. After heating and extrusion friction, hammering and friction of the stamping friction separation mechanism 2, and vibration screening by the vibrating screening mechanism 3, the separation of the electrode material and the metal sheet of the current collector is formed.

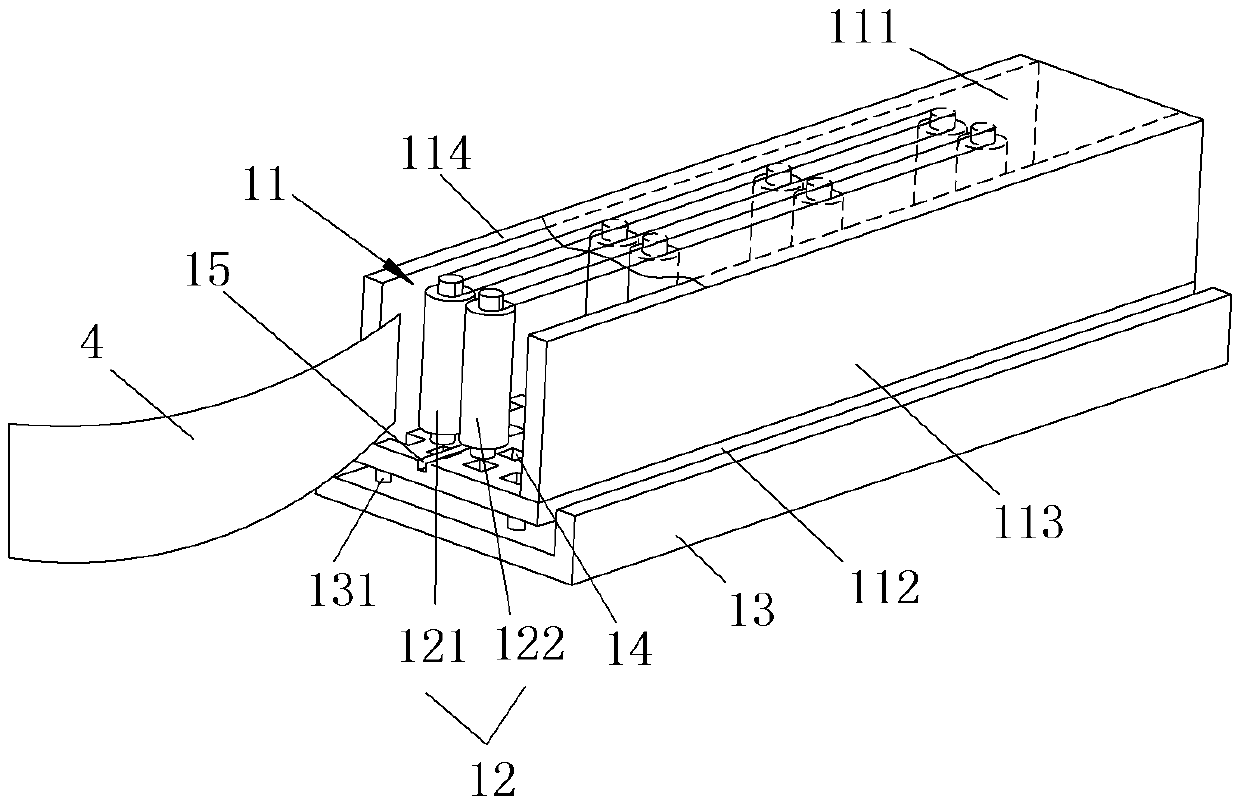

[0028] Specifically, such as figure 2 As shown, the thermal separation mechanism 1 includes a square heating chamber 11 as a whole. The heating chamber 11 is a square cavity structure formed by connecting a top plate 111, a bottom plate 112, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com