Full closed-loop control system and method based on servo press without sensor

A servo press and control system technology, applied in presses, manufacturing tools, etc., can solve the problems of being easily affected by electromagnetic interference and noise, affecting the speed and efficiency of stamping strokes, and the workpiece is easy to wrinkle, so as to achieve reliability and anti-interference Improve performance, overcome fuselage deformation, and solve overshoot effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention are given below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all belong to the protection scope of the present invention.

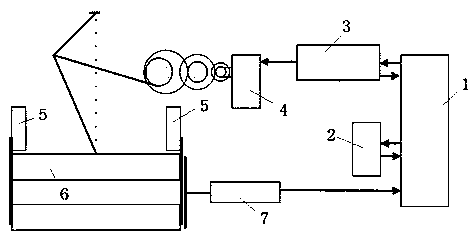

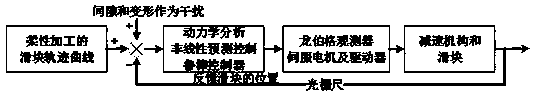

[0031] The brand-new control method adopted by the present invention is a fully closed-loop position control method of the servo press based on the sensorless method. The system hardware architecture diagram of the servo press used in this method is as attached figure 1 As shown, the position sensor of the servo motor 4 is no longer used, but the model is reconstructed according to the detected current and voltage signals, and the current motor position, speed and torque values can be estimated.

[0032] The sensorless servo press full-closed-loop servo control system of the present invention includes a servo press, the servo press h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com