Wastewater treatment system and method

A waste water treatment system and waste water technology, applied in textile industry waste water treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as poor resource utilization, achieve significant economic and environmental benefits, and improve treatment Efficiency, the effect of reducing the amount of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

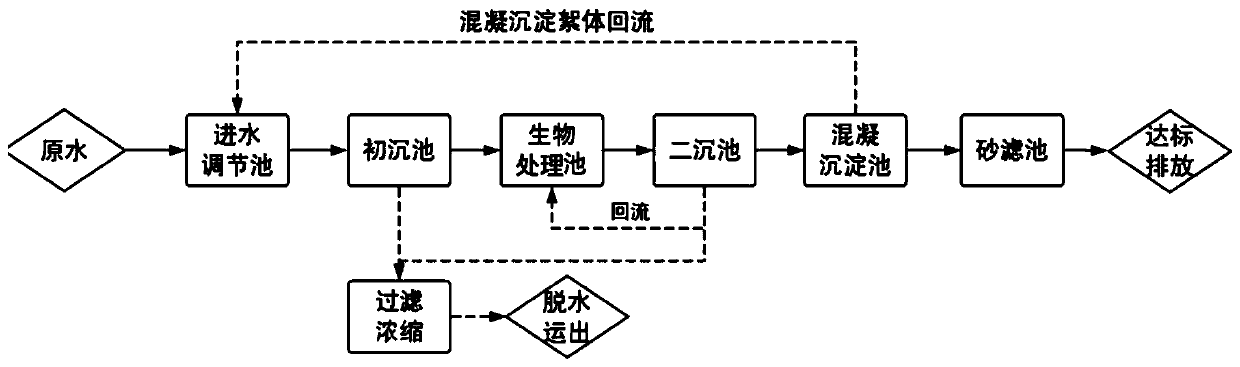

[0048] At room temperature, the contents of antimony and COD in the influent water samples of printing and dyeing wastewater from waterworks were determined. The coagulation and sedimentation flocs in the third settling tank are directly returned to the influent adjustment tank at a reflux ratio of 3%, and the influent water is subjected to adsorption pretreatment. The treatment process adopted is as follows figure 1 shown. Among them, the rate ratio of flocs and printing and dyeing wastewater input into the water adjustment tank is set to 1:6, and the flocs are adsorbed for 120 minutes and then precipitated. The removal rate of COD reached 22.5%, and the removal rate of antimony reached 24.6%, indicating that the coagulation and sedimentation flocs were returned to the influent adjustment tank to pretreat the influent to a certain extent, but the degradation efficiency of antimony and COD limited.

Embodiment 2

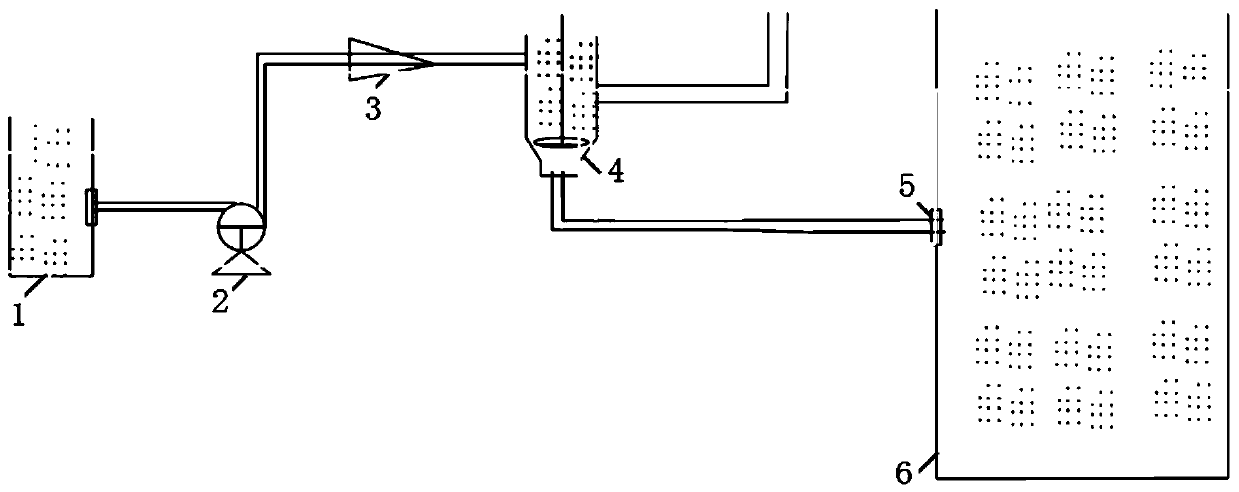

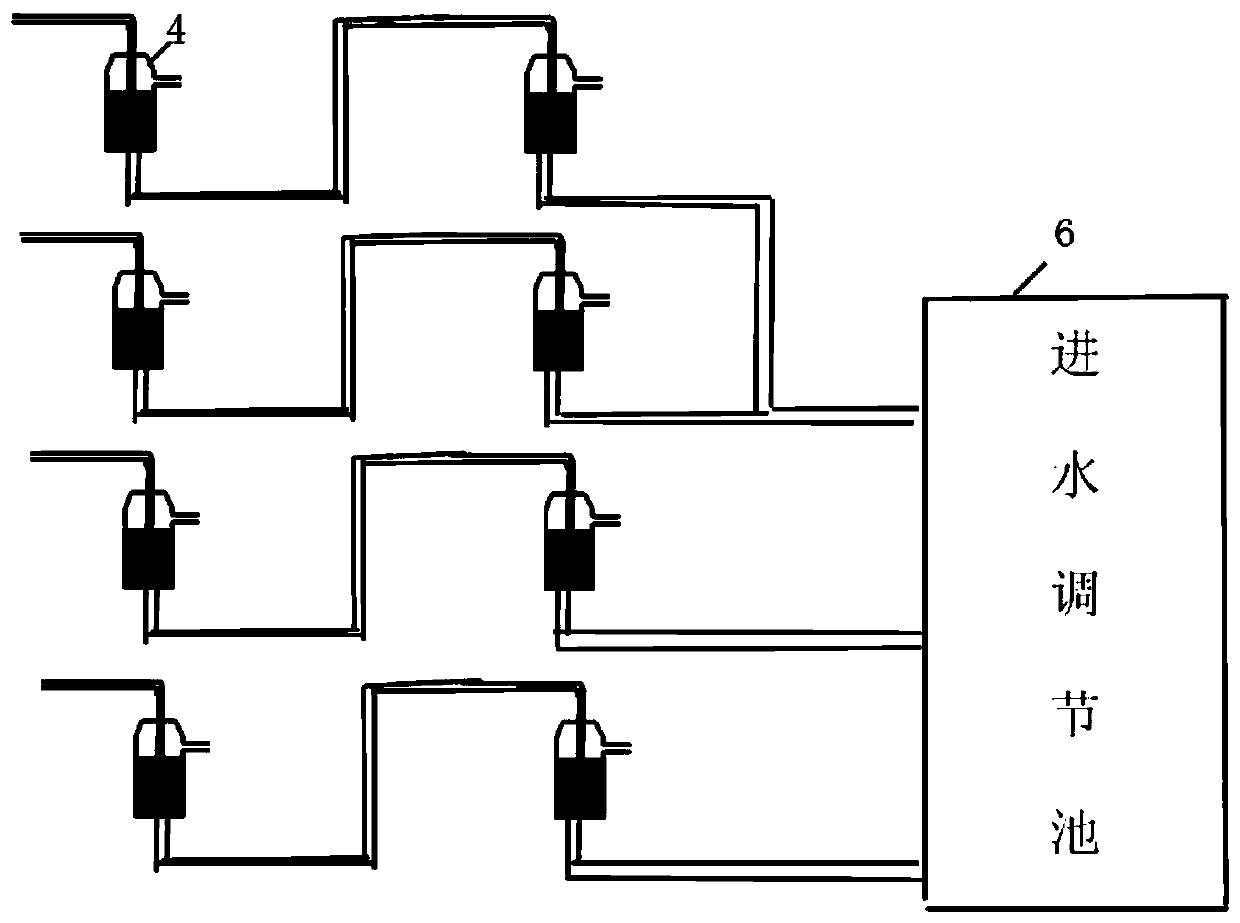

[0050] At room temperature, the contents of antimony and COD in the influent water samples of printing and dyeing wastewater from waterworks were determined. The coagulation and sedimentation flocs in the third settling tank are returned to the pipeline of the water inlet tank at a reflux ratio of 3%. After the flocs pass through the primary separation device, they are directly returned to the water inlet adjustment tank to perform adsorption pretreatment on the water inlet. The primary separation device can be a magnetic floc separator. After the flocs and water are separated, the effluent flows into the triple sedimentation tank through the pipeline, and the flocs enter the inflow adjustment tank. Among them, the rate ratio of flocs and printing and dyeing wastewater input into the water adjustment tank is set to 1:6, and the flocs are adsorbed for 120 minutes and then precipitated, and then the water samples in the water tank are tested. The removal rates of antimony reach...

Embodiment 3

[0052] At room temperature, the contents of antimony and COD in the influent water samples of printing and dyeing wastewater from waterworks were determined. The coagulation and sedimentation flocs in the third settling tank are returned to the pipeline of the water inlet tank at a reflux ratio of 3%, and the flocs pass through the floc magnetization separator as the primary separation device and the floc air flotation separation device as the secondary separation device After that, it is directly returned to the influent adjustment tank, and the influent is subjected to adsorption pretreatment. After the flocs and water are separated, the effluent flows into the triple sedimentation tank through the pipeline, and the flocs enter the inflow adjustment tank. Among them, the rate ratio of flocs and printing and dyeing wastewater input into the water adjustment tank is set to 1:6, and the flocs are adsorbed for 120 minutes and then precipitated, and then the water samples in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com