Kitchen waste stirring kettle reactor

A technology of kitchen waste and stirred tank, which is applied in the field of stirred tank reactors, can solve the problems of complex secondary processing of kitchen waste oil, unsuitable for installation and use in residential areas, long collection and storage time, etc., and achieves a small footprint , reduce emissions and waste of resources, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

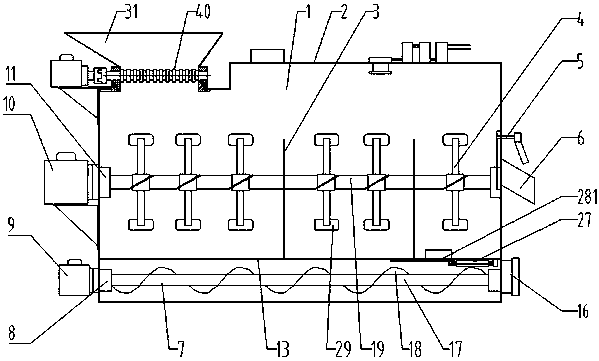

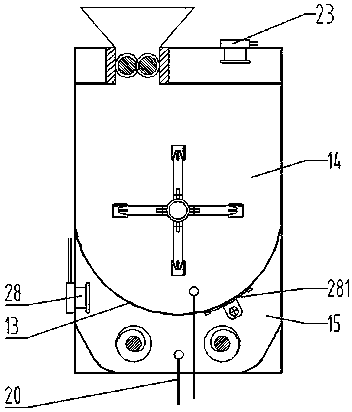

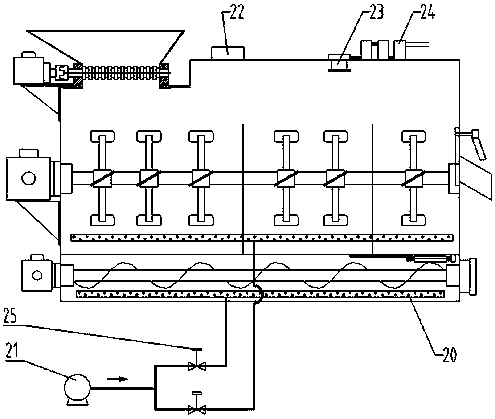

[0026] figure 1 , 2 , 3, 4, the present invention includes kettle body 1, kettle cover 2, compartment plate 3, first agitator 4, discharge valve 5, first discharge port 6, second agitator 7, second shaft seal Device 8 , first motor reducer 10 , first shaft seal device 11 , tank bottom filter plate 13 , first reaction chamber 14 , second reaction chamber 15 . The first reaction chamber 14 is provided with a feed port directly connected to the discharge port of the above crusher for feeding the crushed food waste and microbial strains. The first reaction chamber 14 is provided with a first discharge port. 6. It is used to discharge the decomposed material of the biochemical reaction of food waste. The first reaction chamber 14 is provided with a filter plate 13 at the bottom of the tank, and the filter plate 13 at the bottom of the tank is provided with holes, grooves or gaps for the leachate of the material to leak to the second Reaction chamber 15. The compartment plate 3 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com