Vinyl chloride polymerization terminator with good low-temperature fluidity, and preparation method and application thereof

A technology of vinyl chloride polymerization and low temperature fluidity, which is applied in the field of vinyl chloride polymerization terminators with good low temperature fluidity, can solve the problems of reducing the polymerization reaction rate, consumption of polymerization initiators, etc., and achieves improved thermal stability performance and good low temperature fluidity. , the effect of excellent low temperature fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

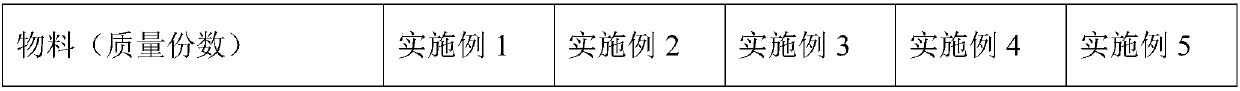

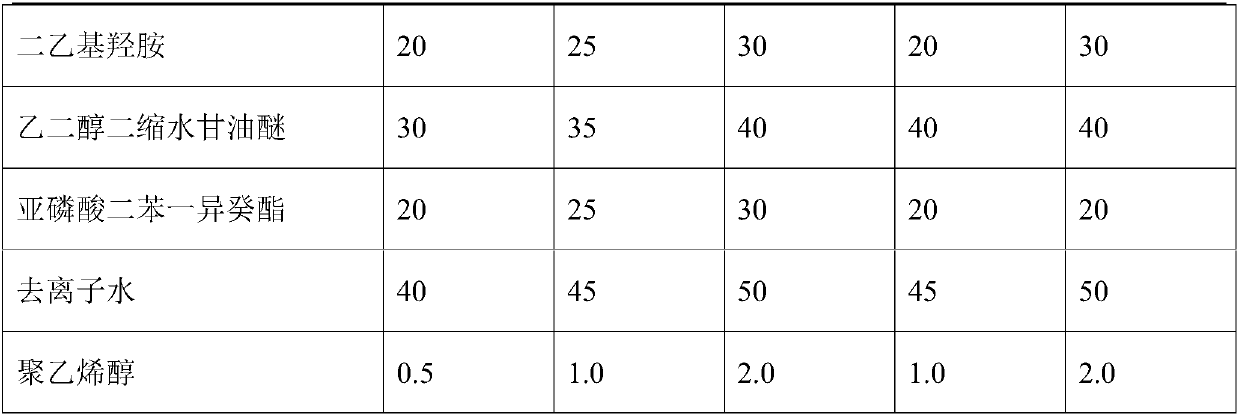

[0024] A vinyl chloride polymerization terminator with good low-temperature fluidity, the components and contents of Examples 1-5 are shown in Table 1.

[0025] Each material component was weighed according to the proportioning in Table 1. Mix 20-30g diethylhydroxylamine, 30-40g ethylene glycol diglycidyl ether, 20-30g diphenyl-isodecyl phosphite, 40-50g deionized water, 0.5-2g polymerization degree 350, alcoholysis degree 55% polyvinyl alcohol aqueous solution with a concentration of 5% was put into a glass beaker and stirred for 10 minutes, then added to a high-speed shear emulsifier and emulsified at a speed of 2000r / min for 30 minutes to obtain a uniform and stable low-temperature flow of each component. Good vinyl chloride polymerization terminator.

[0026] Table 1

[0027]

[0028]

[0029] The vinyl chloride polymerization terminator with good low-temperature fluidity prepared in Examples 1-5 was used to terminate the vinyl chloride polymerization reaction.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com