Low-cost method for cleanly extracting vanadium from vanadium slag

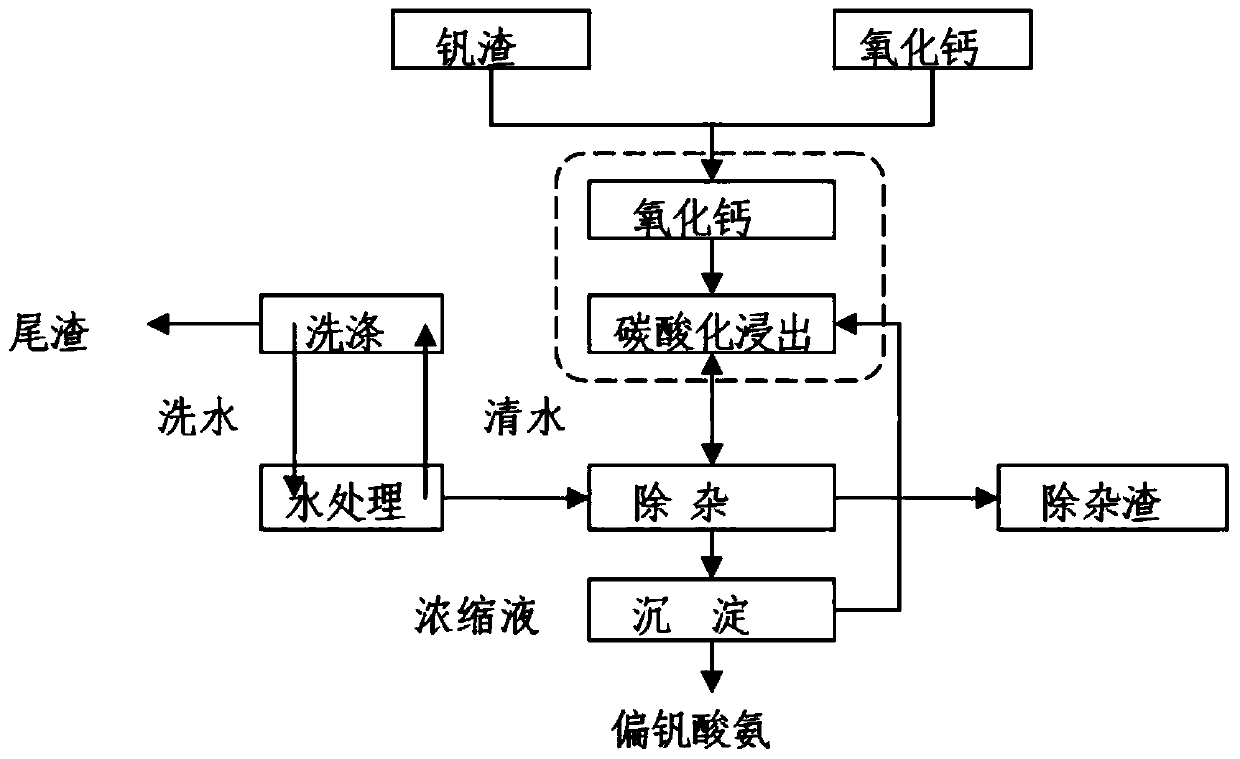

A low-cost, vanadium slag technology, applied in the field of vanadium slag cleaning and vanadium extraction at low cost, can solve the problems of wastewater and solid waste, achieve the effects of small washing water, lower production costs, and easy washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The composition of the following vanadium slag is (%):

[0029] TV TFe CaO TiO 2

SiO 2

P MgO MnO Al 2 O 3

9.55 29.3 2.48 13.3 14.65 0.052 2.4 8.6 2.55

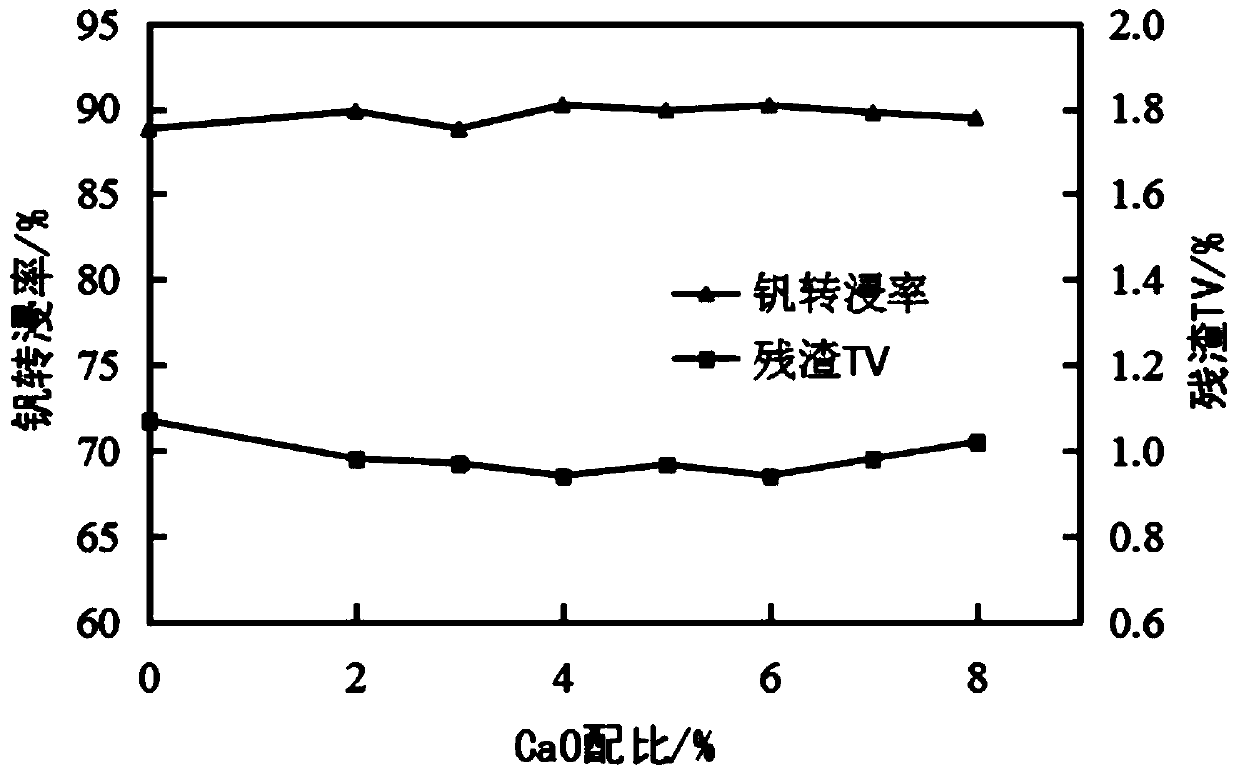

[0030] Mix the vanadium slag and calcium oxide with different ratios and then roast to obtain roasted clinker. The roasting temperature is 850°C and the roasting time is 90min. and vanadium-containing leaching solution to detect the vanadium content (TV) in the residue and the vanadium transfer rate. For the specific results, see figure 2 shown.

[0031] from figure 2 It can be seen that the method of the present invention adopts alkali leaching, and the allowable range of calcium oxide ratio fluctuation is large. When the amount of calcium oxide added is 0-8%, the content of vanadium in the residue is about 1%, and the conversion rate of vanadium basically reaches 1%. 90%.

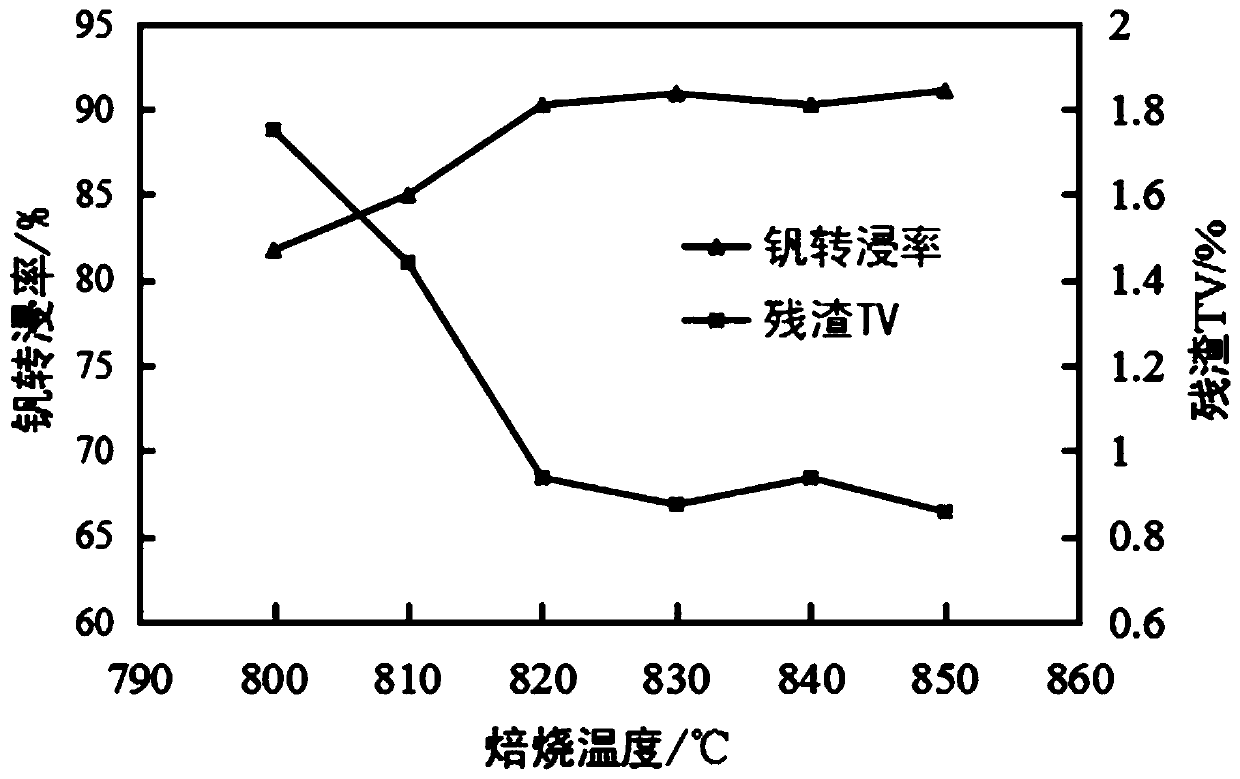

[0032] Add 5% calcium oxide to the vanadium slag and mix it for 90min to obtain calci...

Embodiment 2

[0036] A method for cleaning vanadium extraction from low-cost vanadium slag, comprising the following steps:

[0037] (1) vanadium slag roasting: 10g vanadium slag and 0.4g calcium oxide are mixed, then gained mixed material is roasted to obtain roasting clinker;

[0038] It was calcined in a muffle furnace at 800 °C for 90 min.

[0039] The composition of vanadium slag used in this example is the same as in Example 1.

[0040] (2) Alkaline leaching: the roasted clinker obtained in step (1) is put into a sodium carbonate solution for alkali leaching, and after solid-liquid separation, residue and vanadium-containing leaching solution are obtained. The leaching time is 0.5h, and the ratio of leaching liquid to solid is 4:1. After testing, the leaching rate of vanadium is 94.2%.

[0041] (3) purification: the residue is washed with clear water, the washing solution is concentrated and mixed with the vanadium-containing leachate to obtain a vanadium-containing mixed solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com