Polishing solution for stainless steel showcase and polishing method

A technology for stainless steel and polishing liquid, applied in the field of polishing liquid and polishing for stainless steel showcases, can solve the problems of inability to obtain satisfactory polishing effect, inability to carry out mass production, complicated appearance, etc., achieve the degradable and usable range, and improve the polishing effect. , the effect of large use meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

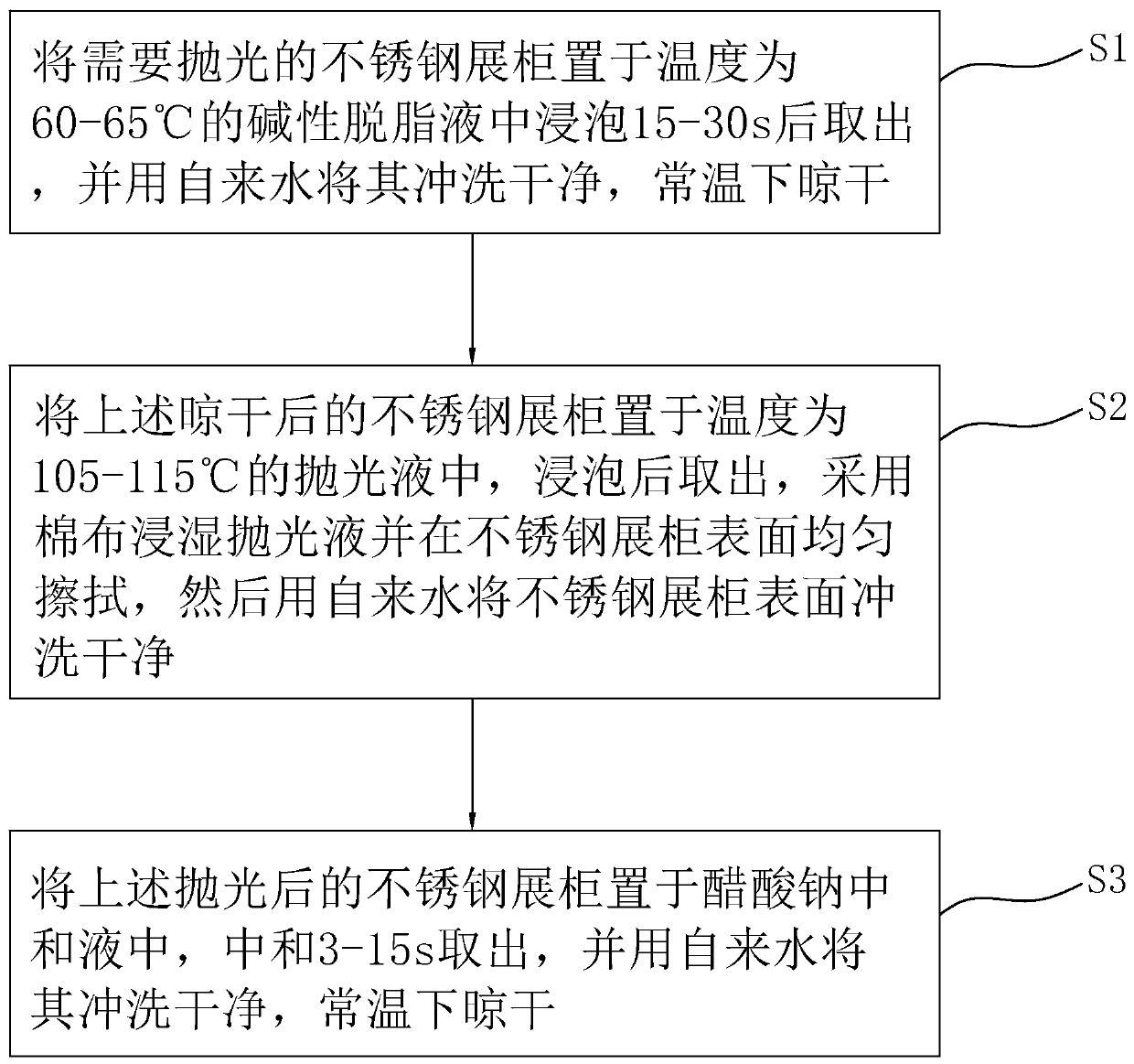

Method used

Image

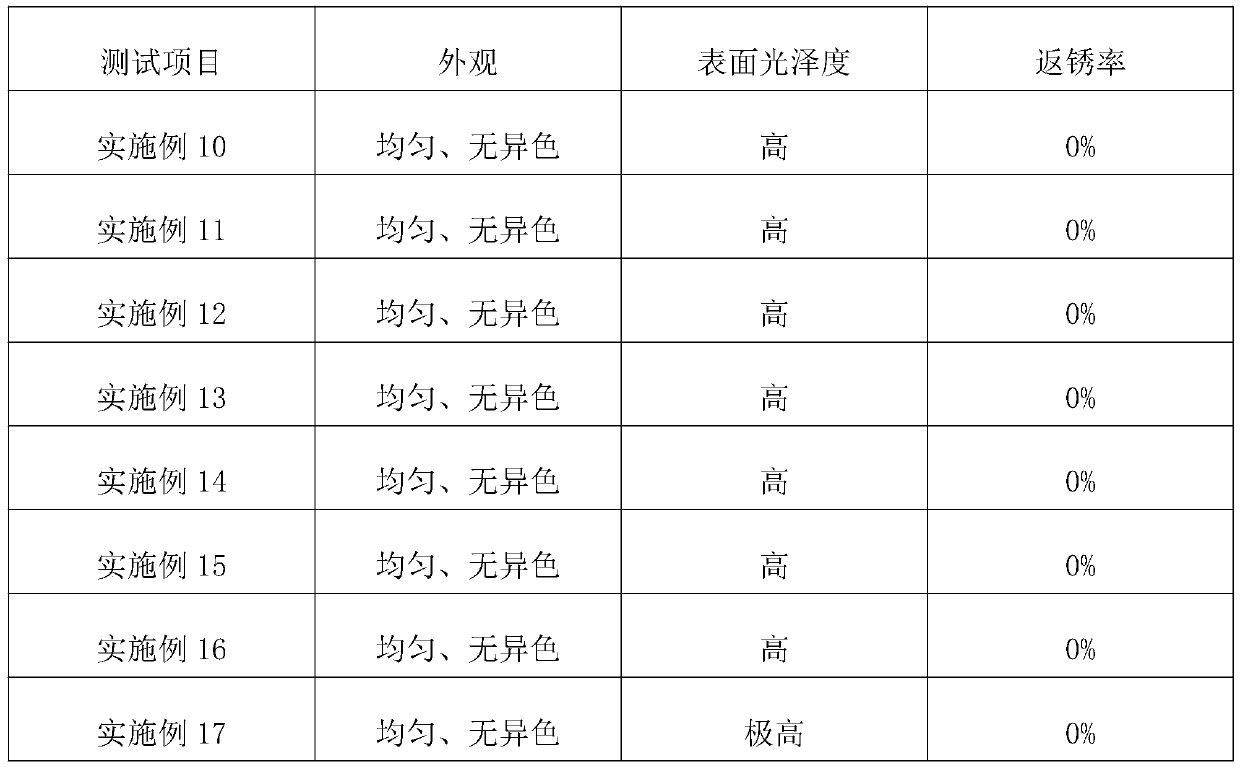

Examples

Embodiment 1-6

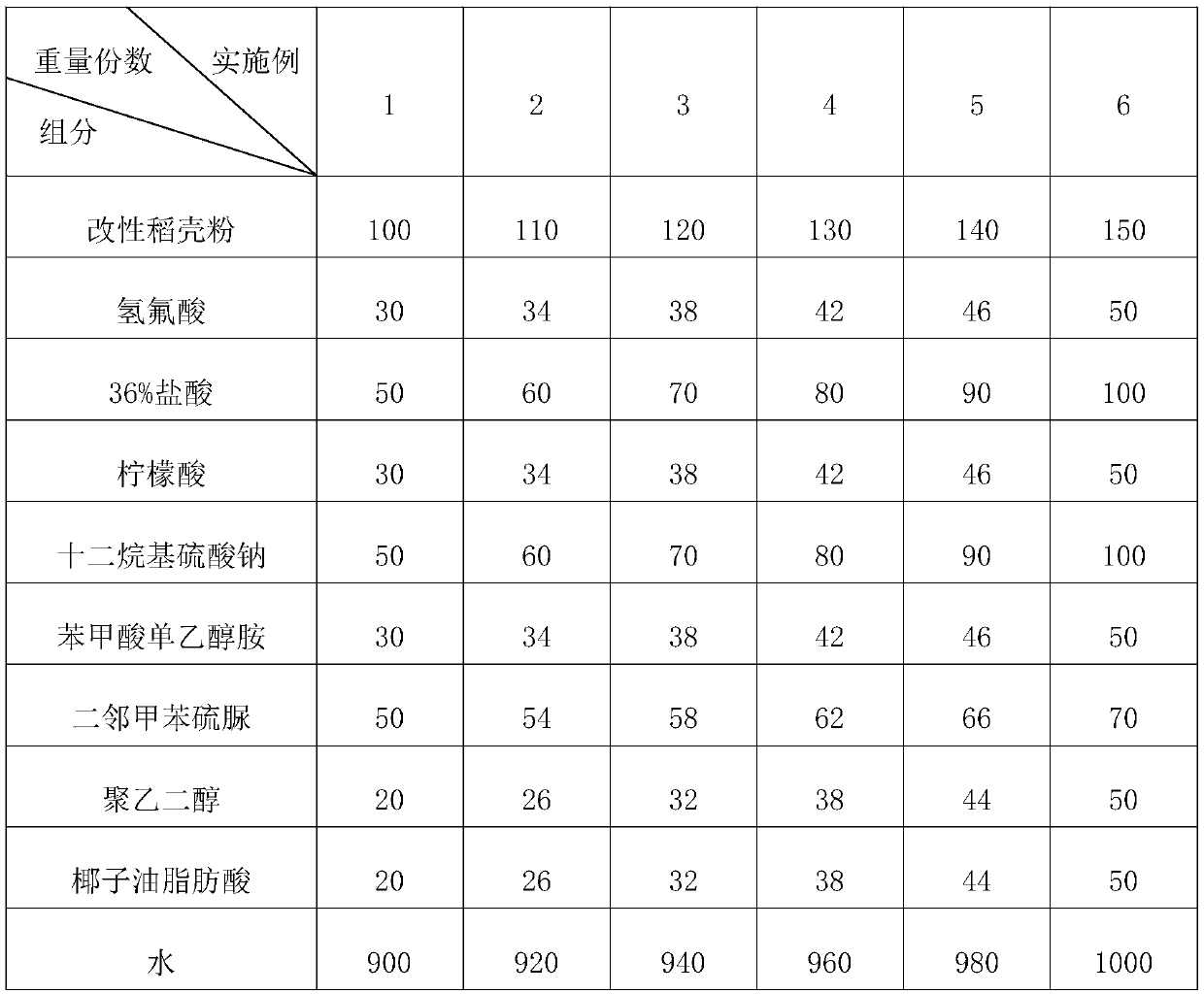

[0041] Embodiment 1-6: A kind of polishing liquid for stainless steel showcase, each component and its corresponding parts by weight are shown in Table 1, wherein the modified bamboo charcoal powder is obtained by the following preparation steps:

[0042] Boil the rice husk in dilute hydrochloric acid with a volume concentration of 10% for 1 hour, wash and dry it, then place it in a high-temperature furnace and carbonize it at 550°C for 1 hour, then raise the temperature to 610°C, and incinerate for 1 hour. Then add ethylene glycol for grinding, and add 0.025% mL of ethylene glycol per 1 g of ashed rice husk powder, and pass through a 300-mesh sieve to obtain modified rice husk powder.

[0043] Each component and parts by weight thereof in table 1 embodiment 1-6

[0044]

Embodiment 7

[0045] Embodiment 7: A polishing solution for stainless steel display cabinets. The difference from Embodiment 1 is that rice husks are ground and passed through a 350-mesh sieve to obtain modified rice husk powder.

Embodiment 8

[0046] Embodiment 8: A kind of polishing solution for stainless steel display cabinets. The difference from Example 1 is that 50 parts of bamboo fibers are also added to the polishing solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com