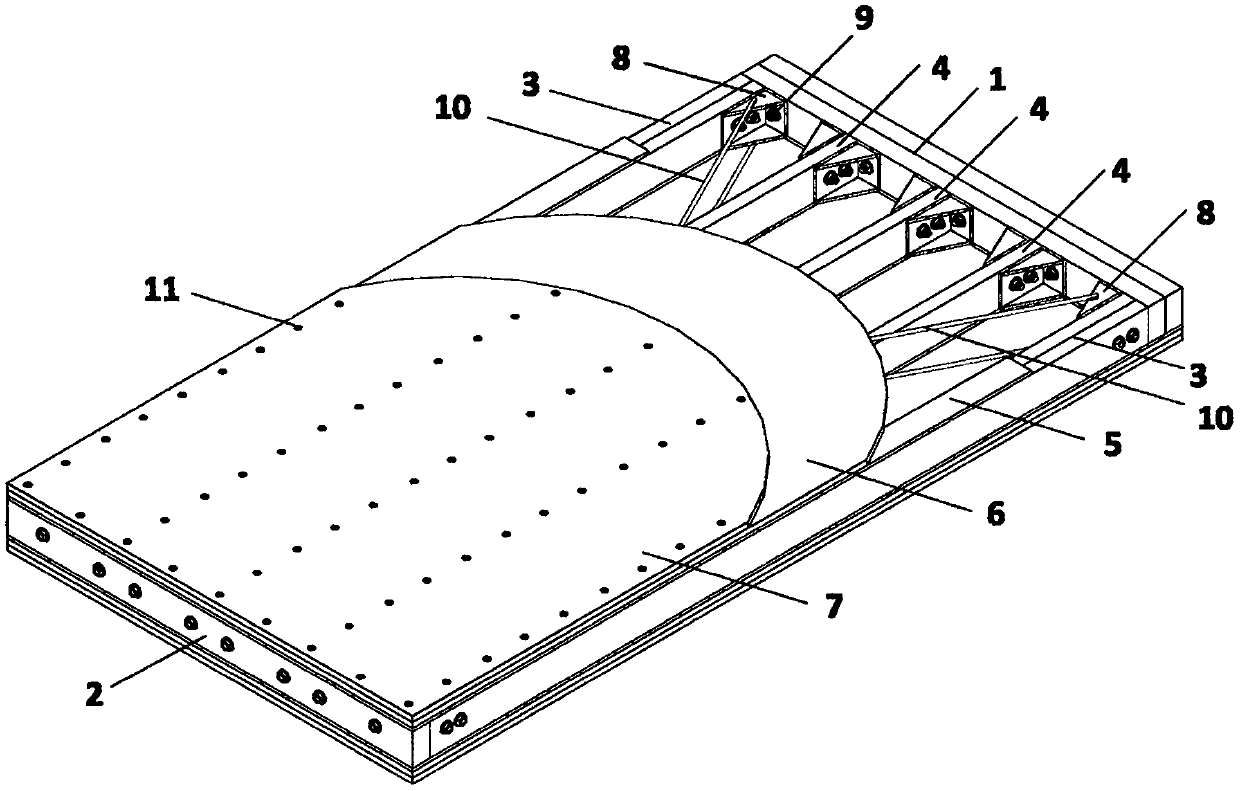

Assembly-type bamboo shearing wall

A prefabricated and shear wall technology, applied in the direction of walls, protective buildings/shelters, building components, etc., can solve the problems of uneconomical and environmentally friendly materials, heavy board materials, single use, etc., and achieve long construction period and low production cost. Low efficiency and good shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

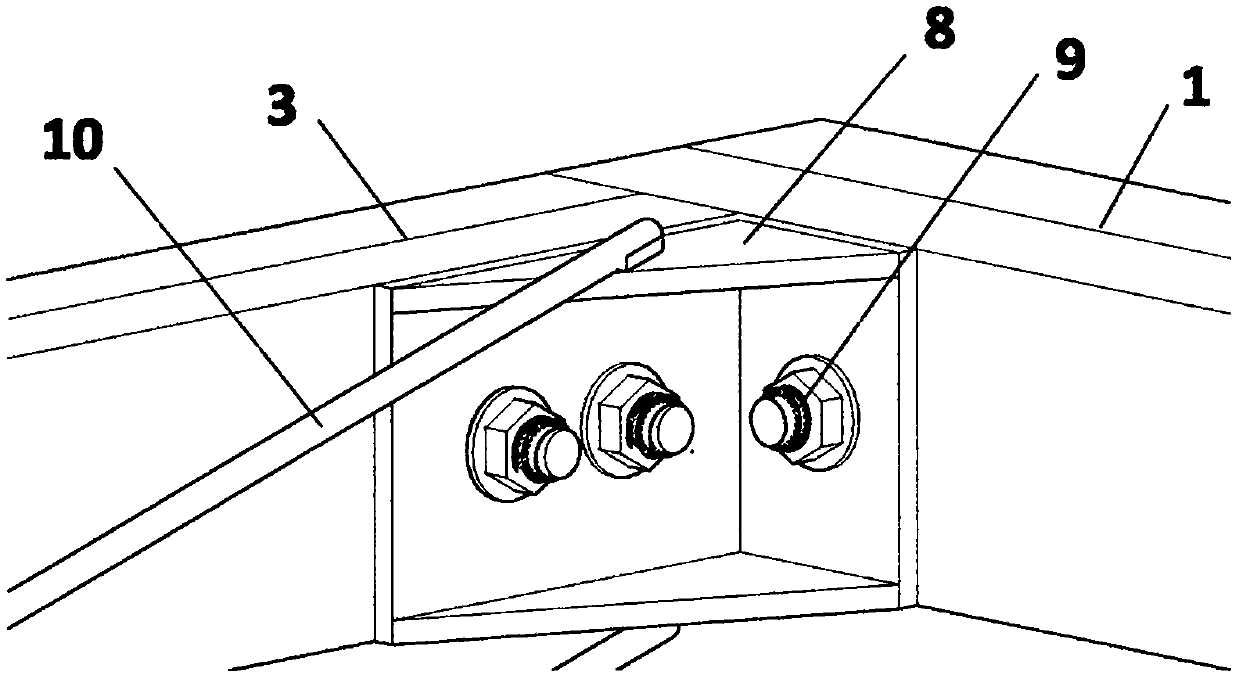

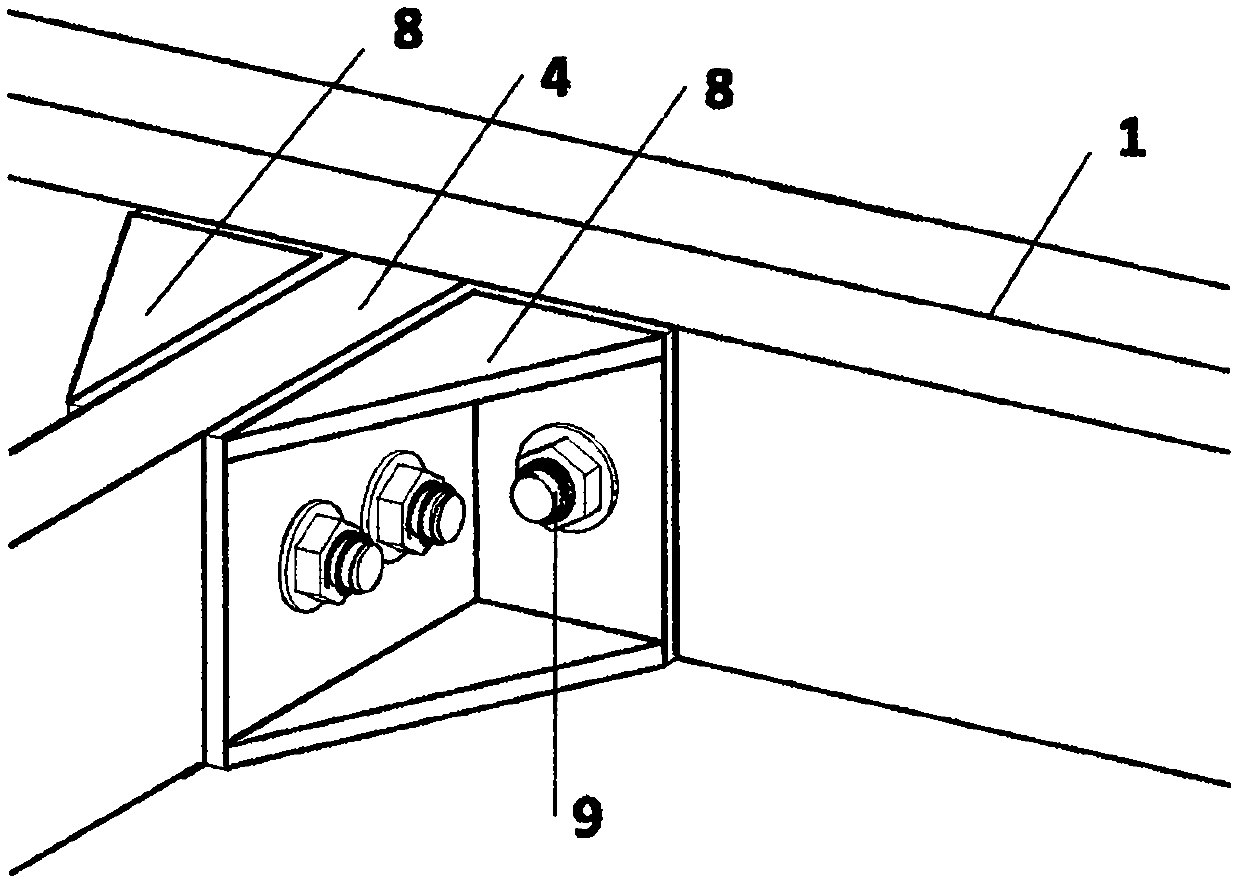

[0032] Embodiment 1: the bamboo material that selection width is 40mm, thickness is 90mm, height is 1000mm is top beam plate, bottom beam plate, and selection width is 30mm, thickness is 90mm, height is that the bamboo material of 1800mm is end column, middle column, steel fill The thickness of the board is 5mm, the thickness of the bamboo plywood is 15mm, the thickness of the gypsum board is 15mm, the material grade of the steel anchor is Q345, the length of the bolt is 60mm, the diameter is 3.2mm, the length of the self-tapping screw is 60mm, the diameter is 2.5mm and the pitch is 150mm. The length, width and thickness of the finished prefabricated bamboo shear wall are 1920mm, 1000mm and 160mm respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com