Sunken spiral inductor structure and fabrication method thereof

A technology of spiral inductors and manufacturing methods, which is applied in the manufacture of inductors/transformers/magnets, inductors, printed inductors, etc., and can solve problems such as high cost, small inductance value, and power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

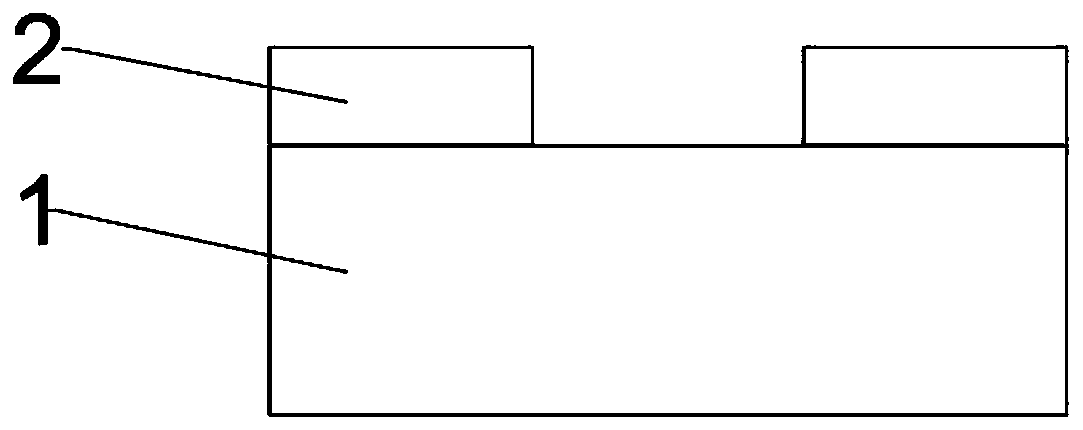

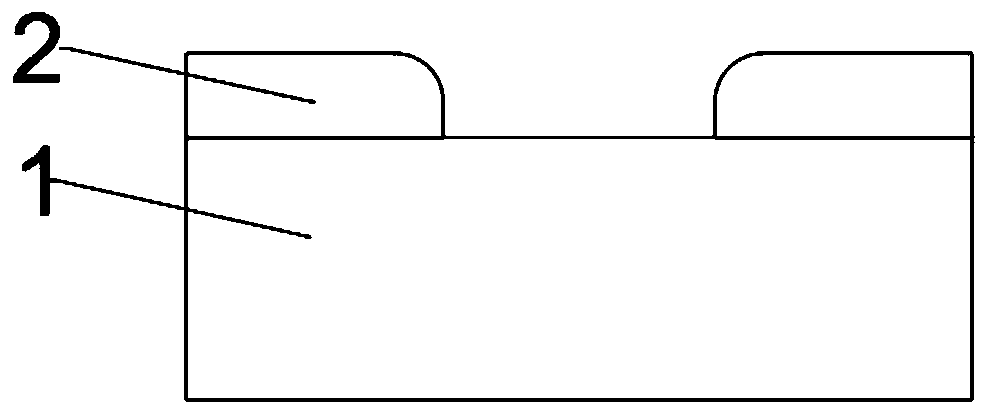

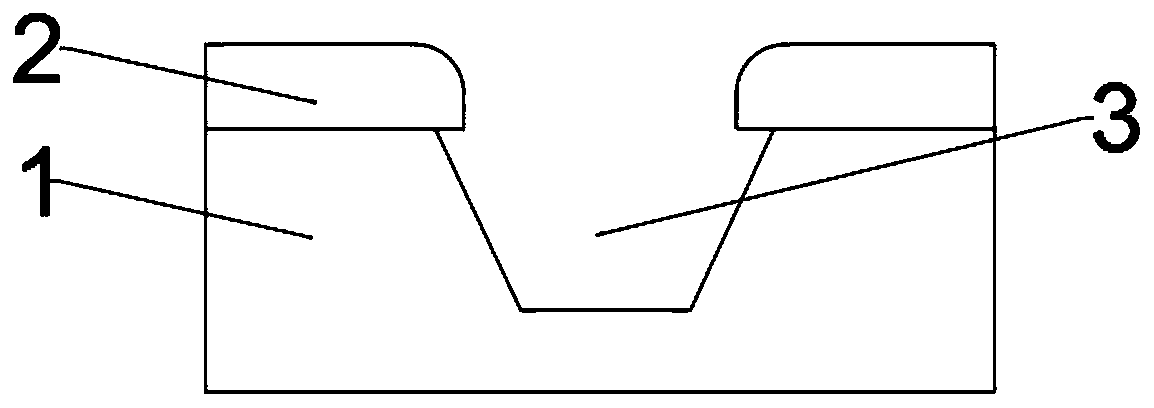

[0050] see Figure 1 to Figure 14, this embodiment provides a method for manufacturing a recessed spiral inductor structure, which can be manufactured on a semiconductor substrate 1 . The method includes the following steps: coating the first photoresist 2, exposing and developing at the groove 3 to be formed, and making an opening above the groove 3 to be formed. A groove 3 is etched on the semiconductor substrate 1, and the redundant first photoresist 2 on the semiconductor substrate 1 is removed. Coating the second photoresist 4 , exposing and developing at the groove 3 to make a window larger than the diameter of the groove 3 . Metal coating is then performed, and metal is sputtered in the groove 3 to form a bottom metal coil 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com