CO2 gas protection welding wire suitable for ultra-low thermal input automatic welding and manufacturing method thereof

A gas shielded welding wire, automatic welding technology, applied in welding/cutting medium/material, welding medium, manufacturing tools, etc., can solve the problem of poor fusion ability of groove edge, narrow welding process adjustment window, uneven distribution of weld metal, etc. problems, to achieve the effect of ensuring toughness and improving the overall performance of the joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

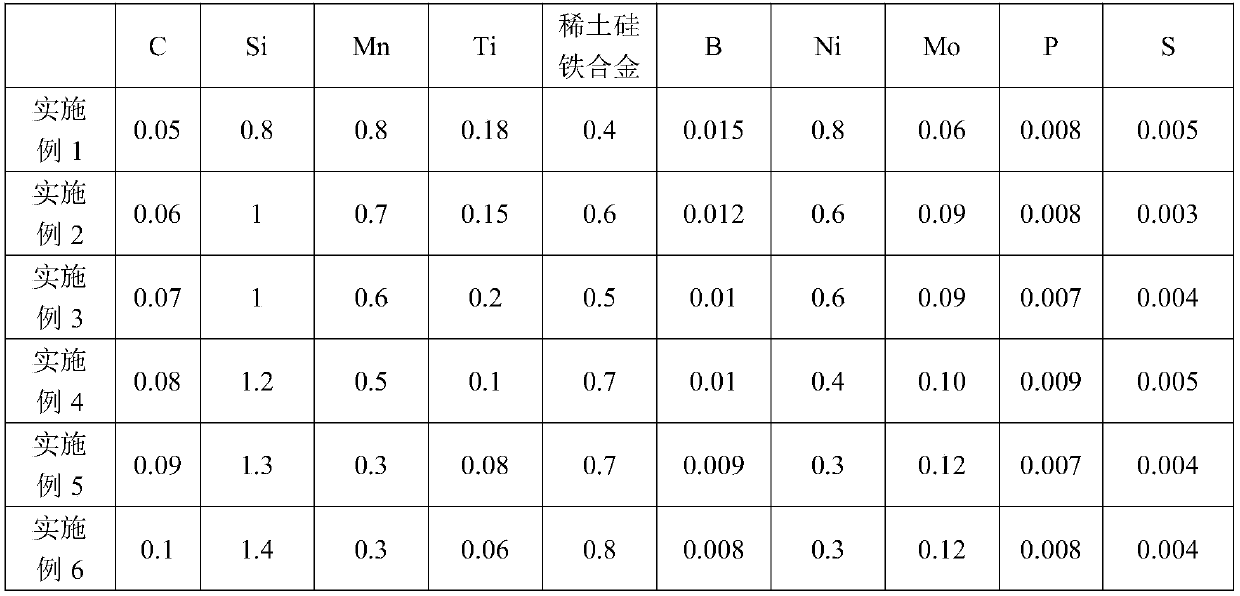

[0059] Table 1 has listed the CO that is suitable for ultra-low heat input automatic welding of embodiment 1-6 2 The mass percentage of each chemical element in the gas shielded welding wire.

[0060] Table 1. (wt%, the balance is Fe and other unavoidable impurities except P and S)

[0061]

[0062] Proportioning is carried out according to each chemical element listed in Table 1, the raw material after the proportioning is put into vacuum electric furnace smelting, the steel ingot after solidification is carried out rolling, drawing and layer winding, finally obtain the suitable ultra-thin of embodiment 1-6 CO for low heat input automatic welding 2 Gas shielded welding wire.

[0063] To verify the obtained CO 2 The welding performance of gas shielded welding wire, the CO of embodiment 1-6 2 Gas shielded welding wire is welded, the CO of embodiment 1-6 2In the all-position welding process of gas shielded welding wire, different welding process parameters are adopted ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com