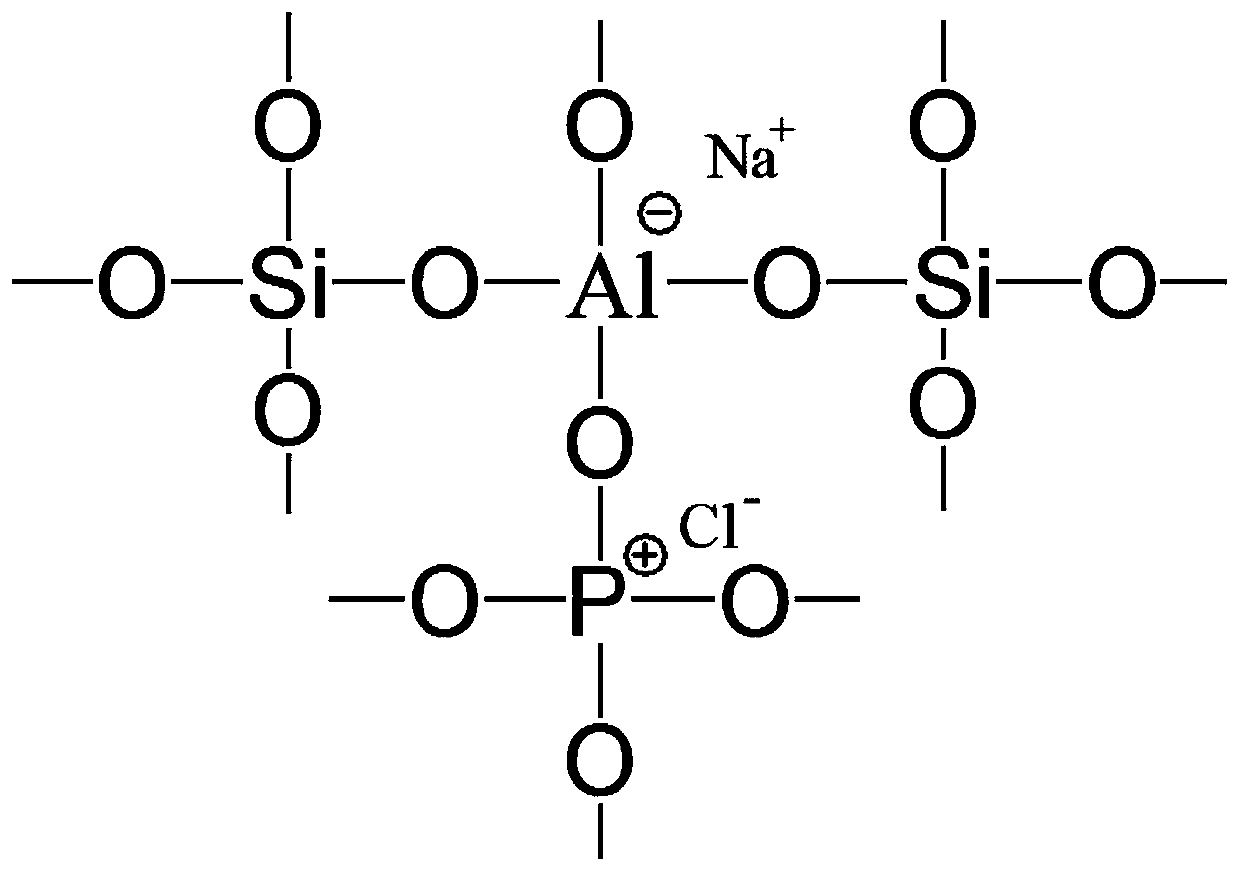

Polychlorinated sodium aluminosilicate phosphate flocculant and preparation method thereof

A polychlorinated sodium silicoaluminophosphate and flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc., can solve problems such as performance defects and poor stability of PASC series flocculants , to achieve the effect of easy storage, good flocculation effect and short flocculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Take 3 parts of aluminum sulfate and 55 parts of aluminum chloride, put them into a container, add 150ml of pure water, stir and mix for 30 minutes to get 150ml of solution A, and keep it for later use;

[0021] 2. Take 20 parts of sodium carbonate, 10 parts of sodium silicate, and 20 parts of sodium phosphate, add them into 150ml of pure water, stir and mix for 30 minutes to obtain 150ml of solution B, and keep it for later use;

[0022] 3. Add the prepared 150ml solution B to the prepared 150ml solution A, and stir while adding it. The stirring speed is maintained at 350-500 rpm, and the stirring can be stopped when the pH value reaches 3.5-4.5;

[0023] 4. Send the mixed solution of solution B and solution A into the aging tank and let it age for 8 hours.

Embodiment 2

[0025] 1. Take 1 part of aluminum sulfate and 40 parts of aluminum chloride, put them into a container, add 150ml of pure water, stir and mix for 30 minutes to get 150ml of solution A, and keep it for later use;

[0026] 2. Take 10 parts of sodium carbonate, 5 parts of sodium silicate, and 10 parts of sodium phosphate, add them into 150ml of pure water, stir and mix for 30 minutes to obtain 150ml of solution B, and keep it for later use;

[0027] 3. Add the prepared 150ml solution B to the prepared 150ml solution A, and stir while adding it. The stirring speed is maintained at 350-500 rpm, and the stirring can be stopped when the pH value reaches 3.5-4.5;

[0028] 4. Send the mixed solution of solution B and solution A into the aging tank and let it age for 8 hours.

Embodiment 3

[0030] 1. Take 5 parts of aluminum sulfate and 60 parts of aluminum chloride, put them into a vessel, add 150ml of pure water, stir and mix for 30 minutes to obtain 150ml of solution A, and keep it for later use;

[0031] 2. Take 5 parts of sodium carbonate, 10 parts of sodium silicate, and 15 parts of sodium phosphate, add them into 150ml of pure water, stir and mix for 30 minutes to obtain 150ml of solution B, and keep it for later use;

[0032] 3. Add the prepared 150ml solution B to the prepared 150ml solution A, and stir while adding it. The stirring speed is maintained at 350-500 rpm, and the stirring can be stopped when the pH value reaches 3.5-4.5;

[0033] 4. Send the mixed solution of solution B and solution A into the aging tank and let it age for 8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com