Alkali zinc-manganese battery containing modified nano zinc powder and preparation method thereof

A nano-zinc powder, zinc-manganese battery technology, applied in dry batteries, battery electrodes, circuits, etc., can solve the problems of insufficient discharge performance, low overall performance, short service life, etc., achieve long service life, improve uniformity, and improve discharge Effects on performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

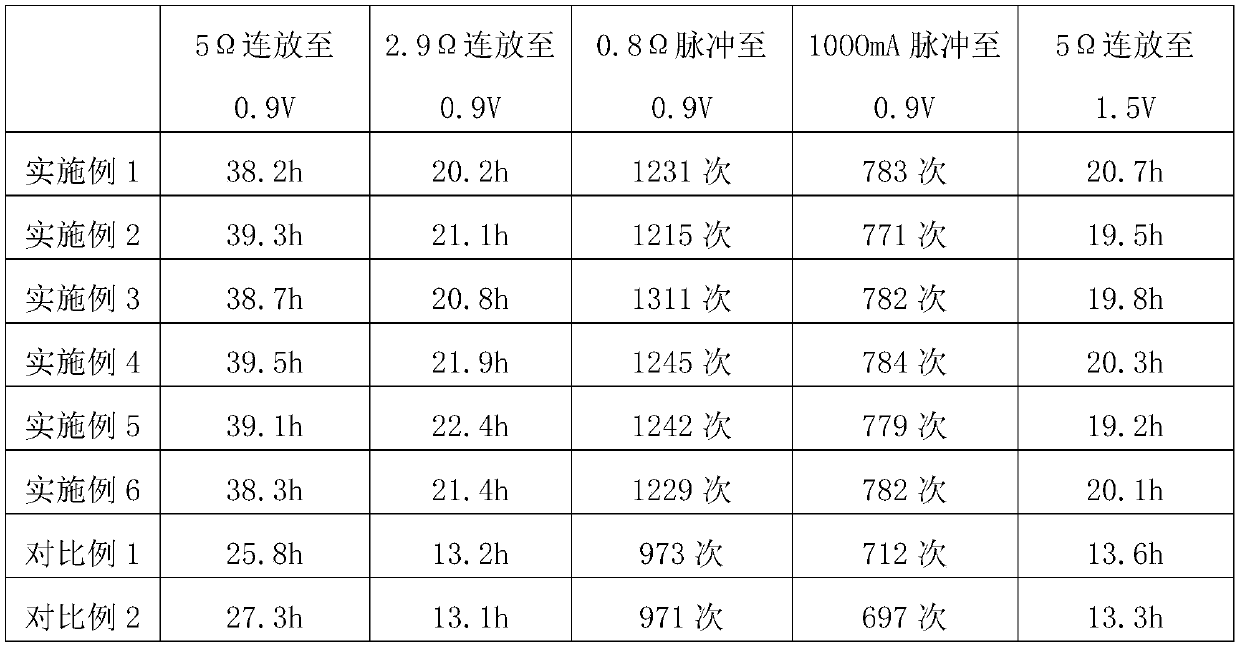

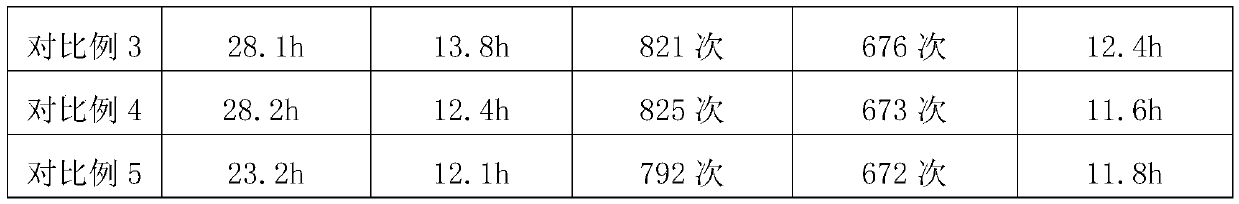

Examples

Embodiment 1

[0041] An alkaline zinc-manganese battery containing modified nano-zinc powder, the alkaline zinc-manganese battery includes a positive electrode ring, a negative electrode zinc paste, a diaphragm and an electrolyte, and the positive electrode ring is composed of electrolytic manganese dioxide, a conductive agent and an electrolyte Composition, the negative electrode zinc paste is composed of the following raw materials in mass fraction: 52wt% modified nano-zinc powder, 2wt% binder, 45wt% electrolyte and 1wt% composite additive.

[0042] The modified nano-zinc powder is a cage-type silsesquioxane modified nano-zinc powder, wherein the particle diameter of the nano-zinc powder is 500nm, and the modification method of the cage-type silsesquioxane-modified nano-zinc powder is as follows: : Add the mixed solution of 60ml methanol and 120ml ethyl acetate in the reactor, add 30mlN-(hydroxyethyl)-N-methylaminopropyltrimethoxysilane, 36ml hydrochloric acid and 80ml deionized under the ...

Embodiment 2

[0060] This embodiment contains the alkaline zinc-manganese battery of modified nano-zinc powder. The zinc-manganese battery structure, raw material composition and preparation method of the zinc-manganese battery are basically similar to those of Example 1. The main difference is that the negative electrode zinc paste The raw material is composed of the following mass fractions: 59wt% modified nano-zinc powder, 3wt% binder, 36wt% electrolyte and 2wt% composite additive. The particle diameter of the nano-zinc powder is 700nm, and the mass ratio of the octahydroxyamino cage silsesquioxane to the nano-zinc powder is 3:1.

[0061] The composite additive is composed of the following raw materials: octahydroxy cage silsesquioxane, ionic liquid modified cage silsesquioxane, ethanolamine phosphate and ethanolamine phosphate derivatives; the octahydroxy cage silsesquioxane The mass ratio of oxane, ionic liquid modified cage silsesquioxane, ethanolamine phosphate and ethanolamine phosp...

Embodiment 3

[0067] This embodiment contains the alkaline zinc-manganese battery of modified nano-zinc powder. The zinc-manganese battery structure, raw material composition and preparation method of the zinc-manganese battery are basically similar to those of Example 1. The main difference is that the negative electrode zinc paste The raw material is composed of the following mass fractions: 68wt% modified nano-zinc powder, 2.5wt% binder, 27wt% electrolyte and 2.5wt% composite additive. The particle diameter of the nano-zinc powder is 900nm, and the mass ratio of the octahydroxyamino cage silsesquioxane to the nano-zinc powder is 50:15.

[0068] The composite additive is composed of the following raw materials: octahydroxy cage silsesquioxane, ionic liquid modified cage silsesquioxane, ethanolamine phosphate and ethanolamine phosphate derivatives; the octahydroxy cage silsesquioxane The mass ratio of oxane, ionic liquid modified cage silsesquioxane, ethanolamine phosphate and ethanolamine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com