Preparation method of Pebax/NH2-MIL-101 mixed-matrix membrane

A mixed matrix membrane, amino terephthalic acid technology, applied in separation methods, chemical instruments and methods, membranes, etc., can solve the problem of not being able to have high permeability and high selectivity at the same time, and achieve excellent separation performance and good economy. Sexual, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

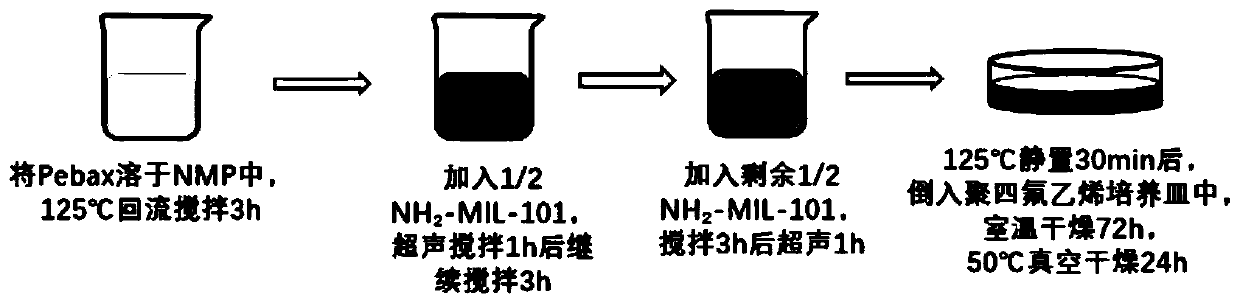

Method used

Image

Examples

specific Embodiment 1

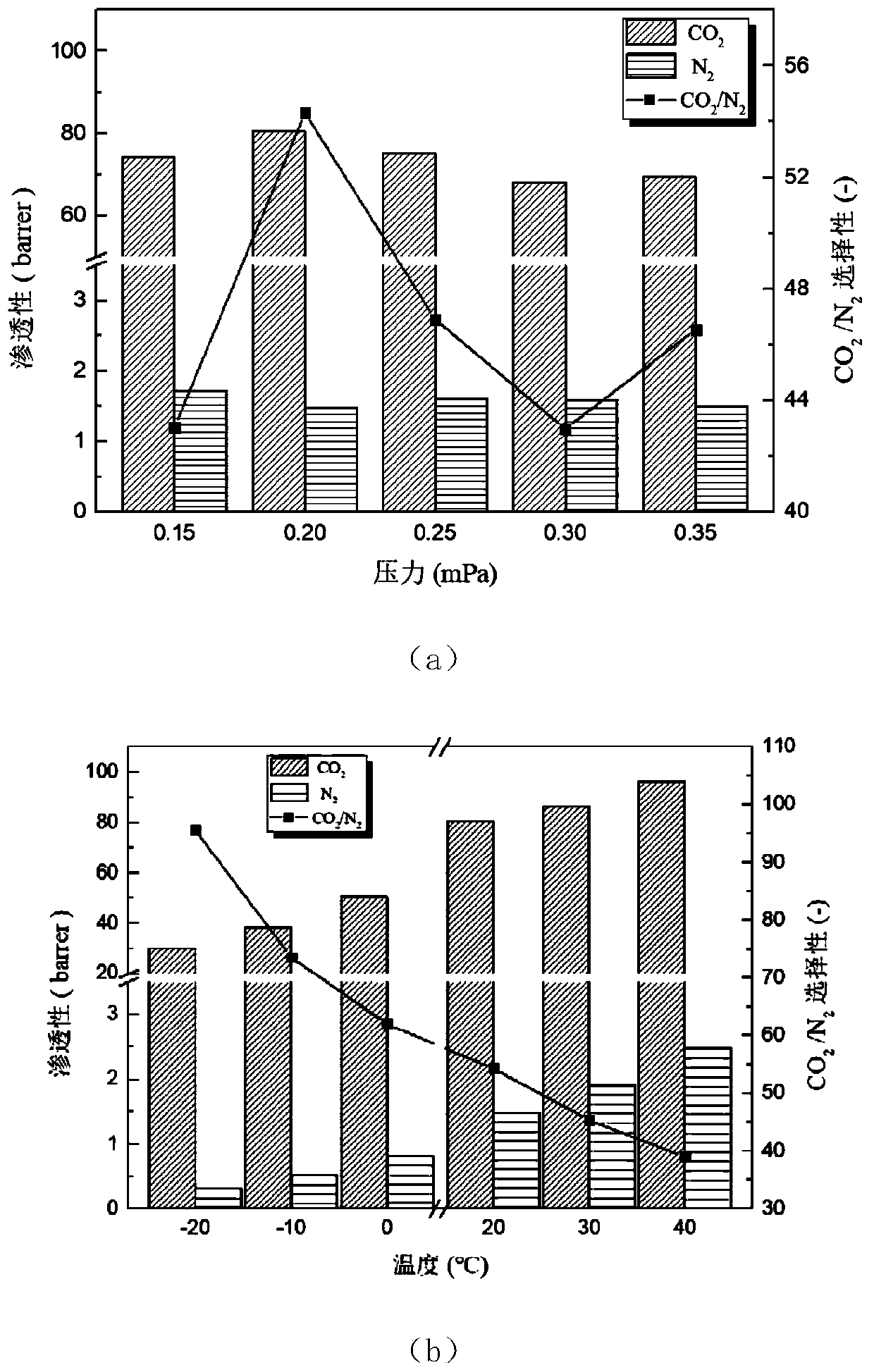

[0021] Test with single gas, CO 2 And N 2 Both are 99.99% pure gas:

[0022] Will CO 2 The inlet pressure is set to 0.2mPa, and the operating temperature is set to 20°C.

[0023] The Pebax / NH prepared in the present invention 2 -MIL-101 (MIL-101 content accounts for 5% of Pebax matrix) membrane material is installed in the membrane tank flange, the upstream of the membrane tank flange is connected to the inlet side, the downstream is the permeate side, and the tail is connected to the soap bubble flowmeter. To test the gas flow at the permeation end, the effective test area of the membrane cell is 8.55cm 2 . After the operating temperature reaches a stable level, the gas is allowed to flow into the membrane cell and stand for a period of time to stabilize the entire permeation behavior. After the system is stable, test the flow rate of the outflowing gas through a stopwatch and a soap bubble flow meter, and repeat 20 times. N 2 Test with CO 2 Same, calculated the permeability a...

Embodiment 1

[0024] Under the conditions of Example 1, Pebax / NH prepared by the method of the present invention 2 -MIL-101 mixed matrix membrane, under the conditions of this example, CO 2 Permeability is 80.5barrer, N 2 Permeability is 1.48barrer, CO 2 / N 2 The selectivity is 54.3.

[0025] In Example 1, a stabilizing valve was used to control the upstream inlet pressure of the membrane tank flange to stabilize.

[0026] In Example 1, the operating temperature was lowered to -20°C to obtain the low-temperature performance of the mixed matrix membrane, CO 2 Permeability is 30.2barrer, N 2 Permeability is 0.32barrer, CO 2 / N 2 The selectivity is 95.6.

[0027] From this specific example, it can be concluded that: Pebax / NH prepared by the present invention 2 -MIL-101 mixed matrix film can get good CO under normal temperature and low temperature environment 2 / N 2 Separation effect, especially excellent CO can be obtained at low temperature 2 / N 2 The selectivity allows the raw materials to be effect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com