Method for preparing polyhydroxyl functional group Ti3C2Tx material through two-step etching method

A technology of polyhydroxyl functionalization and etching method, which is applied in the field of preparation of polyhydroxyl functional group Ti3C2Tx, can solve the problems of chemical activity and electrochemical performance reduction, and achieve good electrochemical performance, high synthesis efficiency, and process controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Prepare 50ml of 50% potassium hydroxide alkaline solution, heat up to 200°C under nitrogen atmosphere, add 1g of Ti 3 AlC 2 Phase material, stirred for 6h, centrifuged at 4200rpm for 10min, washed with water to neutral wash to obtain pre-etched product A;

[0027] (2) Submerge the obtained pre-etching product A in 50 ml of HF aqueous solution, the mass fraction of HF is 40%, and stir and react under nitrogen atmosphere for 24 hours;

[0028] (3) After the reaction in step (2), the reaction solution was centrifuged at 4200 rpm for 10 minutes, washed with water until neutral, and then freeze-dried at -60°C for 24 hours. After drying, Ti 3 C 2 T x Material.

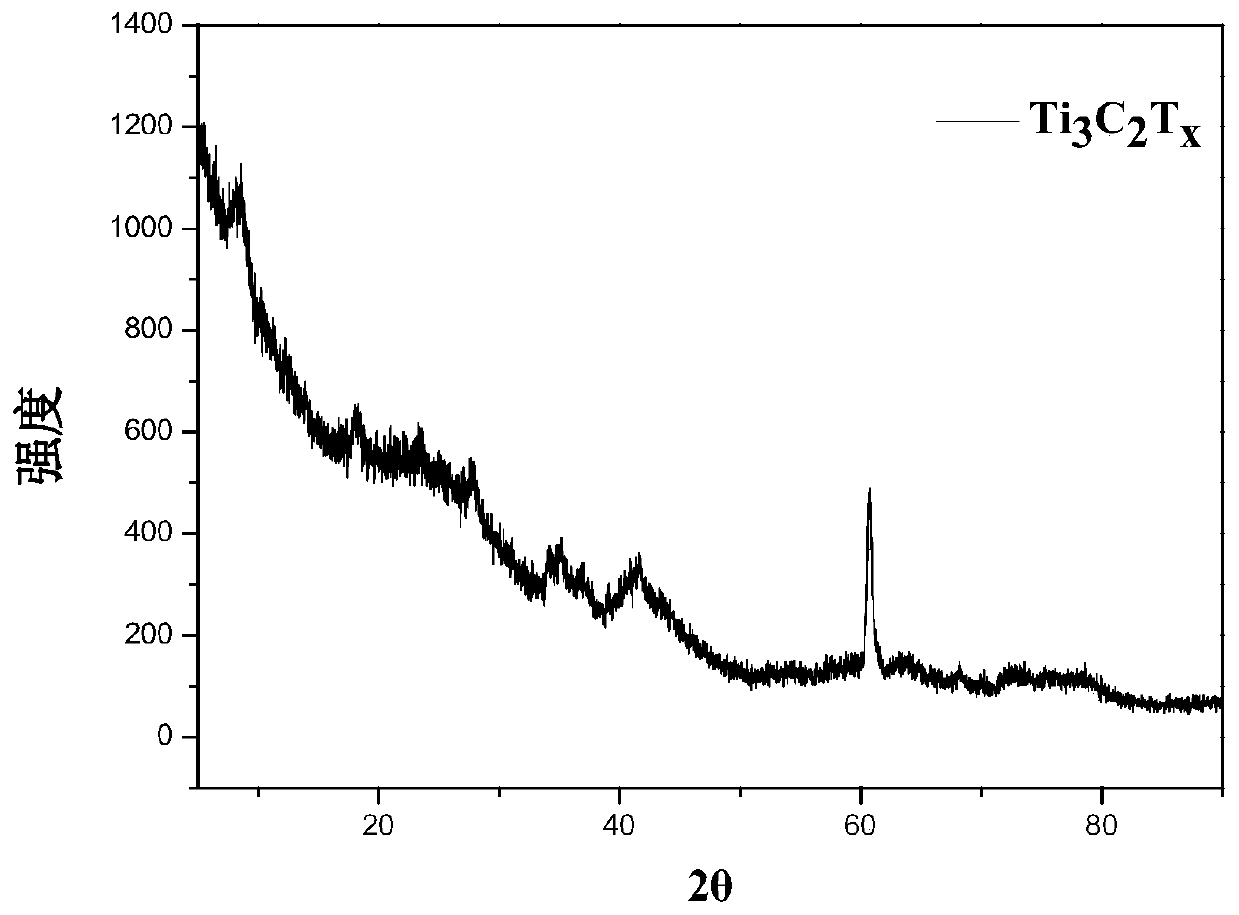

[0029] Depend on figure 1 It can be seen that the (002)(004)(110) peaks and the successful preparation of Ti 3 C 2 T x .

Embodiment 2

[0031] (1) Prepare 50ml of 40% potassium hydroxide alkaline solution, heat up to 150°C under nitrogen atmosphere, add 0.5g of Ti 3 AlC 2 phase material, stirred and reacted for 12 hours, centrifuged at 4200rpm for 10 minutes, washed with water to neutral washing to obtain pre-etched product A;

[0032] (2) Submerge the obtained pre-etching product A in 50 ml of HF aqueous solution, the mass fraction of HF is 40%, and stir and react under nitrogen atmosphere for 24 hours;

[0033] (3) After the reaction in step (2), the reaction solution was centrifuged at 4200 rpm for 10 minutes, washed with water until neutral, and then freeze-dried at -60°C for 24 hours. After drying, Ti 3 C 2 T x Material.

[0034] Depend on image 3 It can be seen that the successful stripping of Ti 3 AlC 2 , yielding Ti with a typical accordion-like structure 3 C 2 T x Material, Figure 4 It can be seen that Ti 3 C 2 T x Two-dimensional sheet structure (with folds).

Embodiment 3

[0036] (1) Prepare 50ml of 30% potassium hydroxide alkaline solution, heat up to 100°C under nitrogen atmosphere, add 0.5g of Ti 3 AlC 2 Phase material, stirred for 18 hours, centrifuged at 4200 rpm for 10 minutes, washed with water to neutral wash to obtain pre-etched product A;

[0037] (2) Submerge the obtained pre-etching product A in 50 ml of HF aqueous solution, the mass fraction of HF is 40%, and stir and react under nitrogen atmosphere for 24 hours;

[0038] (3) After the reaction in step (2), the reaction solution is centrifuged at 4200rpm for 10min, washed with water until neutral, and dried at a temperature of 60°C for 24h. After drying, Ti 3 C 2 T x Material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com