Production system for preparing formaldehyde, paraformaldehyde, methylal and hexamethylene tetramine from methanol

A technology of hexamethylenetetramine and paraformaldehyde is applied in the preparation of carbon-based compounds, the preparation of organic compounds, chemical instruments and methods, etc. To maximize utilization, reduce production costs, and reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with embodiment the present invention is described in further detail:

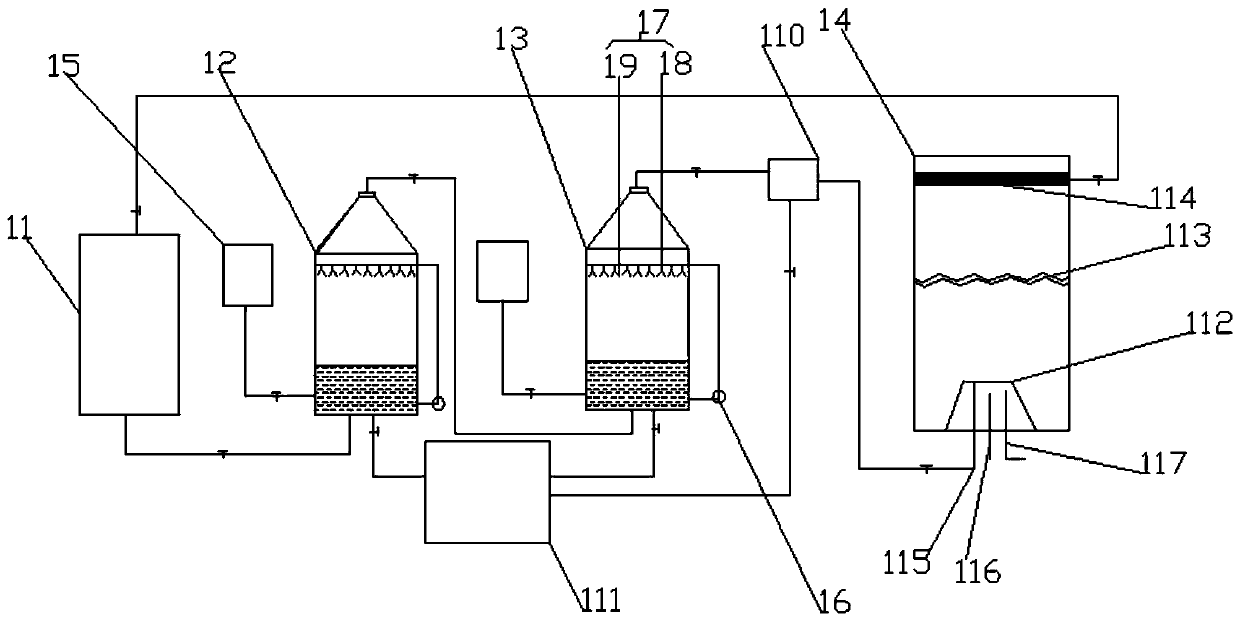

[0040] A production system for preparing formaldehyde, paraformaldehyde, methylal and hexamethylenetetramine from methanol, comprising the following processes:

[0041] S1, methanol and air are used as raw materials to obtain formaldehyde mixed gas through oxidation, and the formaldehyde mixed gas is recovered to obtain a low-concentration formaldehyde solution, and the unrecovered formaldehyde mixed gas is absorbed by an absorption tower to obtain light aldehyde solution and waste gas;

[0042] S2, using methanol and the low-concentration formaldehyde solution obtained in the process S1 as raw materials, successively pass through the resin reactor, reaction tower, rectification tower, and cooler to obtain methylal;

[0043] S3, the low-concentration formaldehyde solution in the process S1 is concentrated by secondary evaporation to obtain a high-concentration formaldehyde solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com