Application of environment-friendly high-temperature yellow agent in textile fabric finishing

A high-temperature resistant and environmentally friendly technology, applied in textiles and papermaking, single-component polyamide rayon, chemical characteristics of fibers, etc., to improve heat resistance, prevent yellowing, and inhibit oxidative degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

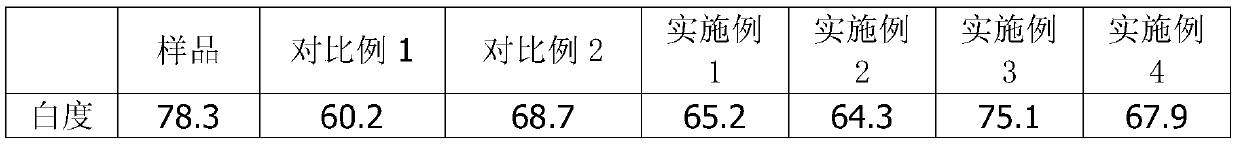

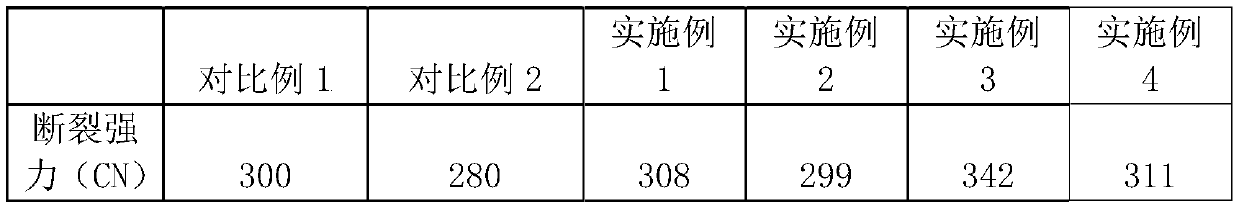

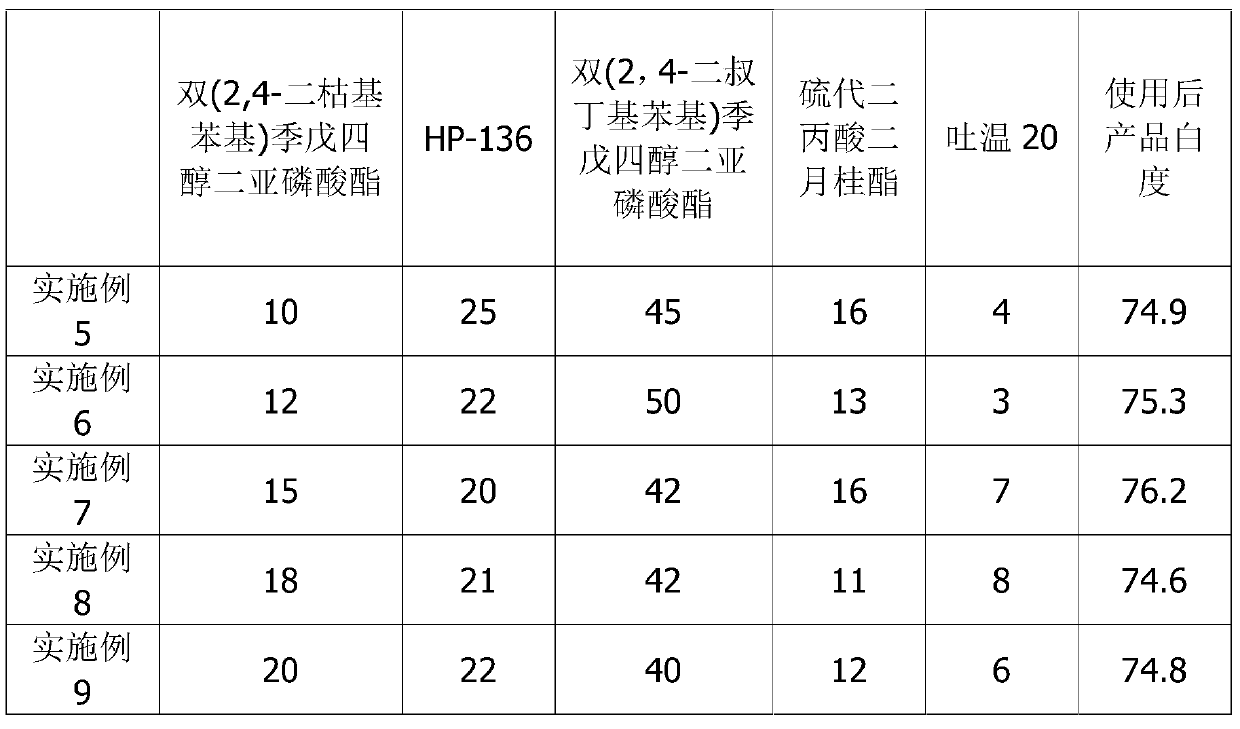

Examples

Embodiment 1

[0030] Example 1: According to the formula, HP-136 (5,7-di-tert-butyl-3-(3,4-dimethylphenyl)-3H-benzofuran-2-one), bis(2,4- Di-tert-butylphenyl) pentaerythritol diphosphite and Tween 20 are mixed, and after standing for 20 minutes, add unmodified bis (2,4-dicumylphenyl) pentaerythritol diphosphite and sulfur Dilauryl dipropionate is replaced, and the anti-yellowing agent of embodiment 1 is obtained after mixing.

[0031] Add the anti-yellowing agent of Example 1 to the white nylon raw material of the underwear for high temperature setting.

Embodiment 2

[0033] Bis(2,4-dicumylphenyl)pentaerythritol diphosphite, dilauryl thiodipropionate, HP-136 (5,7-di-tert-butyl-3-(3,4- Dimethylphenyl)-3H-benzofuran-2 ketone), two (2,4-di-tert-butylphenyl) pentaerythritol diphosphite and Tween 20 are mixed, obtain embodiment 2 after mixing uniformly Anti-yellowing agent.

[0034] Add the anti-yellowing agent of Example 2 to the white nylon raw material of the underwear to carry out high temperature setting.

Embodiment 3

[0036] According to the recipe, HP-136 (5,7-di-tert-butyl-3-(3,4-dimethylphenyl)-3H-benzofuran-2-one), bis(2,4-di-tert-butyl Phenyl) pentaerythritol diphosphite and Tween 20 are mixed, after standing for 20 minutes, add modified bis(2,4-dicumylphenyl) pentaerythritol diphosphite and thiodipropionate diphosphite Lauryl ester, after mixing homogeneously, obtains the anti-yellowing agent of embodiment 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com