Filling process of refrigerant gas cylinder

A technology for refrigerants and gas cylinders, which can be used in gas processing/storage purposes, container filling methods, fixed-capacity gas storage tanks, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

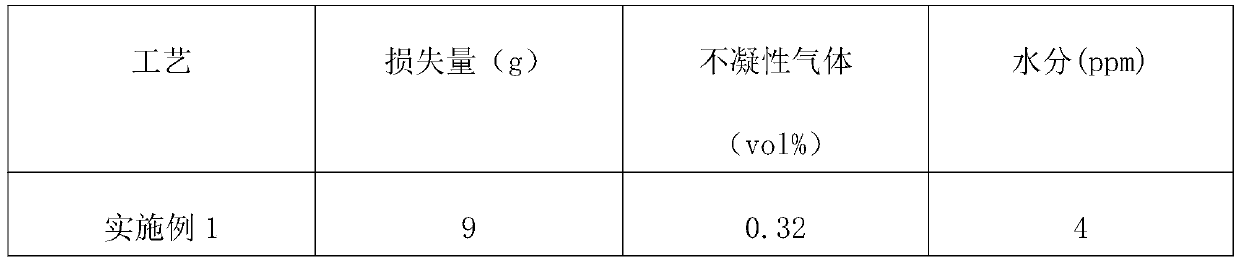

Examples

Embodiment 1

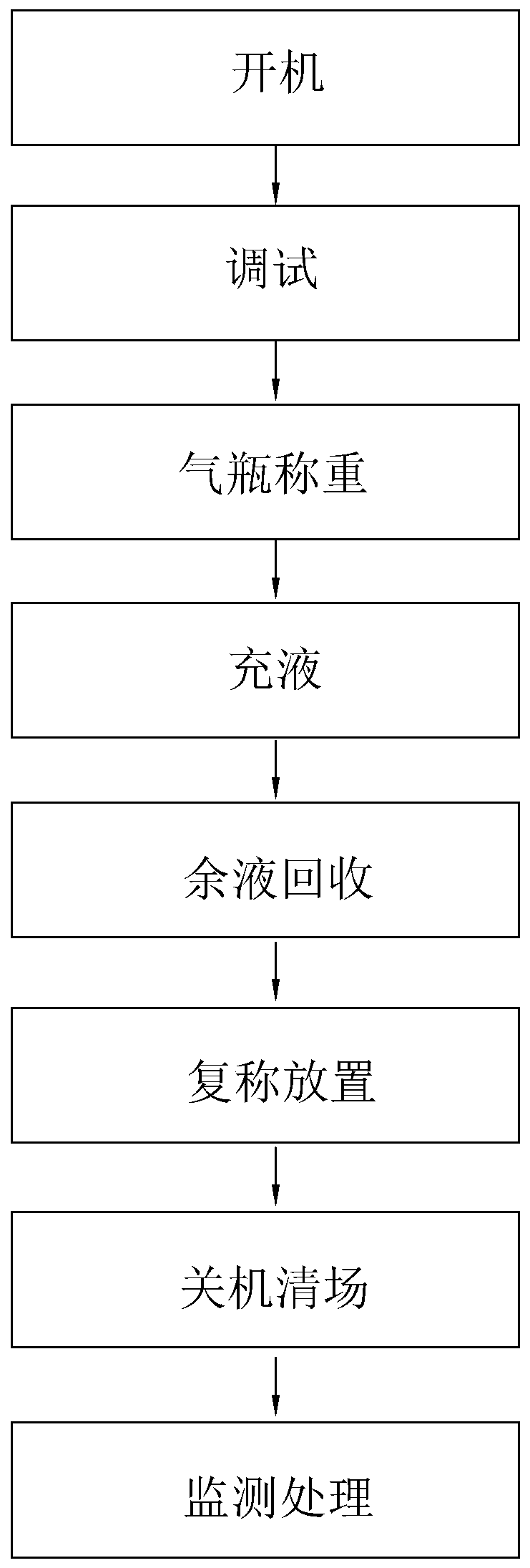

[0040] Embodiment 1: a kind of filling process of refrigerant cylinder, specifically comprises the following steps:

[0041] Step 1, start up: first turn on the main power switch, turn on the cooling water circulation system, then turn on the vacuum pump and recovery compressor, and slowly open the valve of the vacuum pump and the inlet and outlet valves of the recovery machine;

[0042] Step 2, commissioning: start the liquid supply pump, adjust the return valve to make the pressure gauge at 5.5kg / cm2;

[0043] Step 3, weighing the gas cylinder: put the gas cylinder on the scale, and record the tare weight, serial number and electronic tag number of the gas cylinder;

[0044]Step 4, liquid filling: connect the liquid filling pipe, first open the vacuum valve, evacuate the liquid filling pipe for 9 seconds, then open the gas cylinder valve to evacuate the gas cylinder for 6 minutes, then close the vacuum, open the cylinder valve and pipeline liquid filling hand valve to carry ...

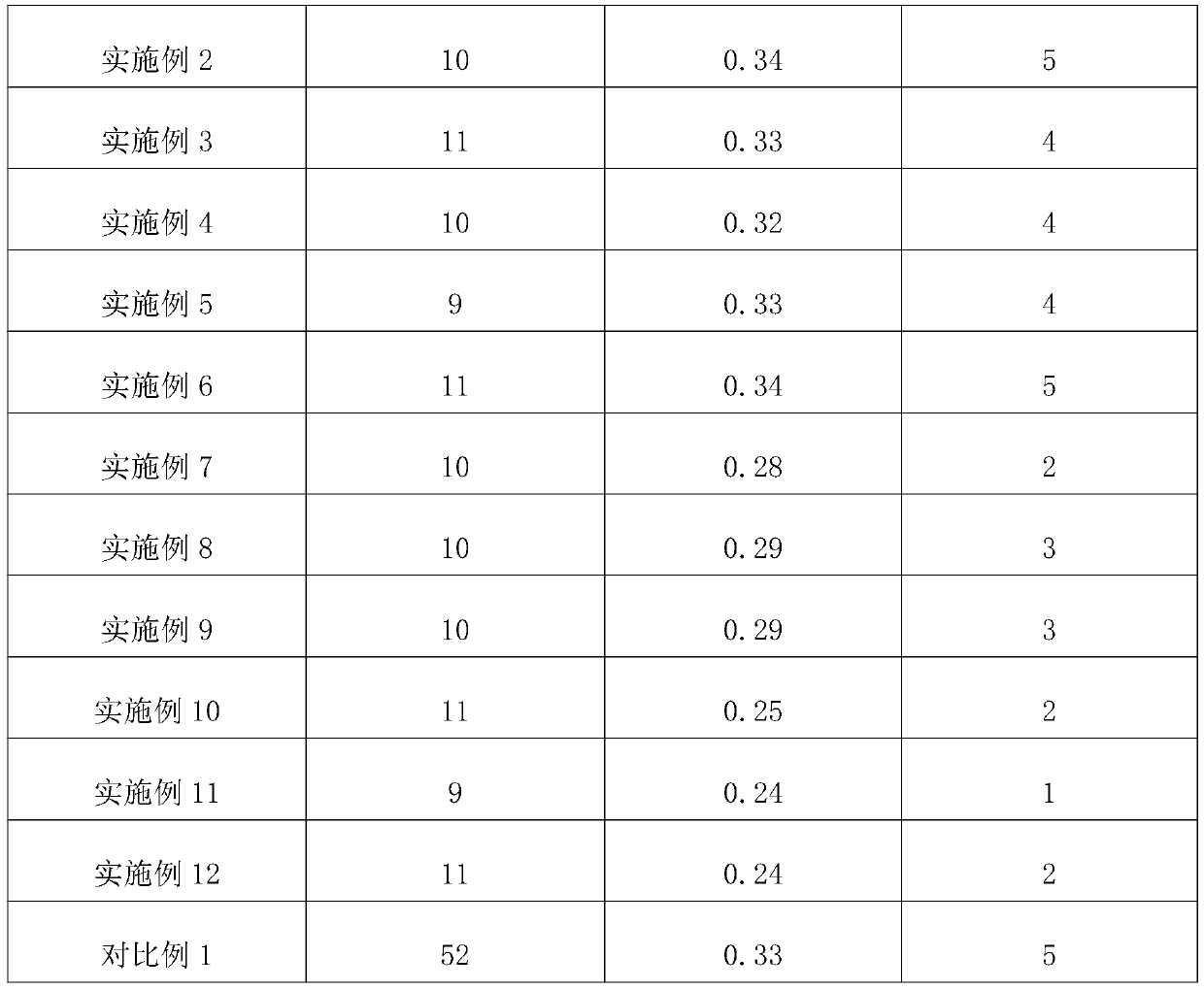

Embodiment 2

[0049] Embodiment 2: A filling process for a refrigerant gas cylinder, which differs from Embodiment 1 in that it specifically includes the following steps:

[0050] Step 1, start up: first turn on the main power switch, turn on the cooling water circulation system, then turn on the vacuum pump and recovery compressor, and slowly open the valve of the vacuum pump and the inlet and outlet valves of the recovery machine;

[0051] Step 2, commissioning: start the liquid supply pump, adjust the return valve to make the pressure gauge at 5kg / cm2;

[0052] Step 3, weighing the gas cylinder: put the gas cylinder on the scale, and record the tare weight, serial number and electronic tag number of the gas cylinder;

[0053] Step 4, liquid filling: connect the liquid filling pipe, first open the vacuum valve, evacuate the liquid filling pipe for 8 seconds, then open the gas cylinder valve to evacuate the gas cylinder for 4 minutes, then close the vacuum, open the cylinder valve and pipe...

Embodiment 3

[0058] Embodiment 3: a filling process of a refrigerant gas cylinder, which differs from Embodiment 1 in that it specifically includes the following steps:

[0059] Step 1, start up: first turn on the main power switch, turn on the cooling water circulation system, then turn on the vacuum pump and recovery compressor, and slowly open the valve of the vacuum pump and the inlet and outlet valves of the recovery machine;

[0060] Step 2, debugging: start the liquid supply pump, adjust the return valve, and make the pressure gauge at 6kg / cm2;

[0061] Step 3, weighing the gas cylinder: put the gas cylinder on the scale, and record the tare weight, serial number and electronic tag number of the gas cylinder;

[0062] Step 4, liquid filling: connect the liquid filling pipe, first open the vacuum valve, evacuate the liquid filling pipe for 10 seconds, then open the gas cylinder valve to evacuate the gas cylinder for 8 minutes, then close the vacuum, open the cylinder valve and pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com