Pre-coating and air-flotation integrated apparatus

A pre-coating and air flotation technology, applied in membrane, membrane technology, semi-permeable membrane separation, etc., can solve the problem of large fluctuations in effluent quality and operation effect, unusable process equipment for water quality changes, and effluent quality that cannot reach discharge. Standards and other issues, to achieve the effect of reducing the pollution load of influent water, reducing the cost of waste residue treatment, and achieving good water treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

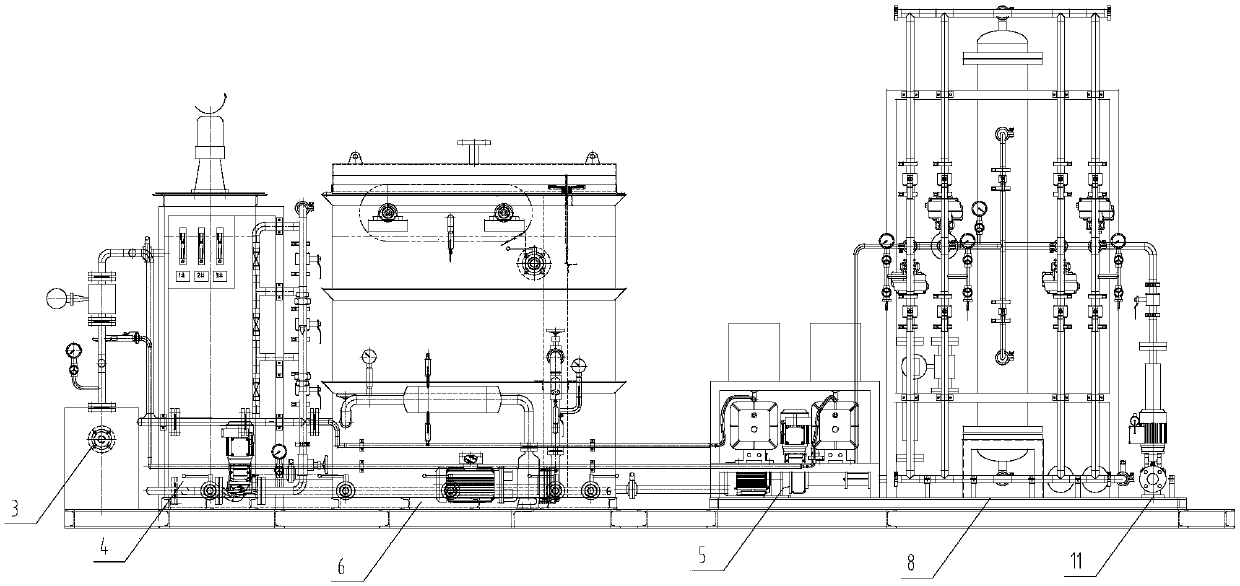

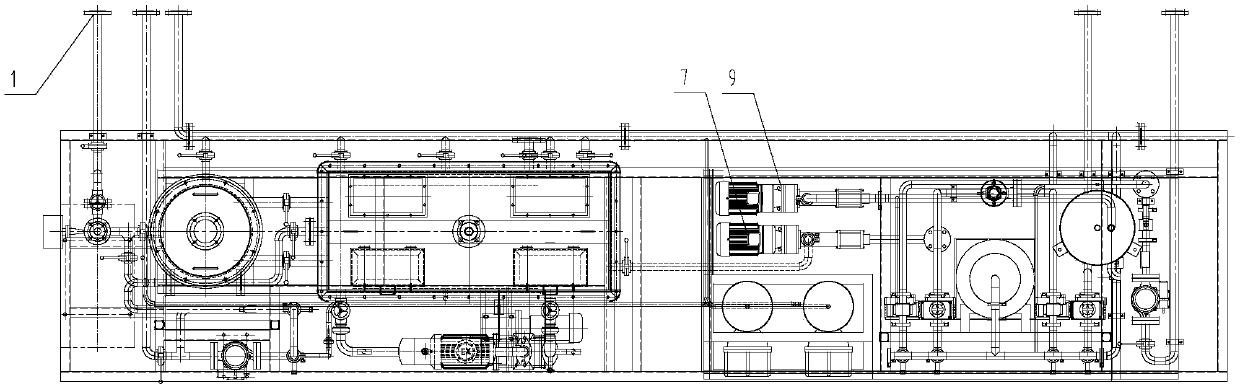

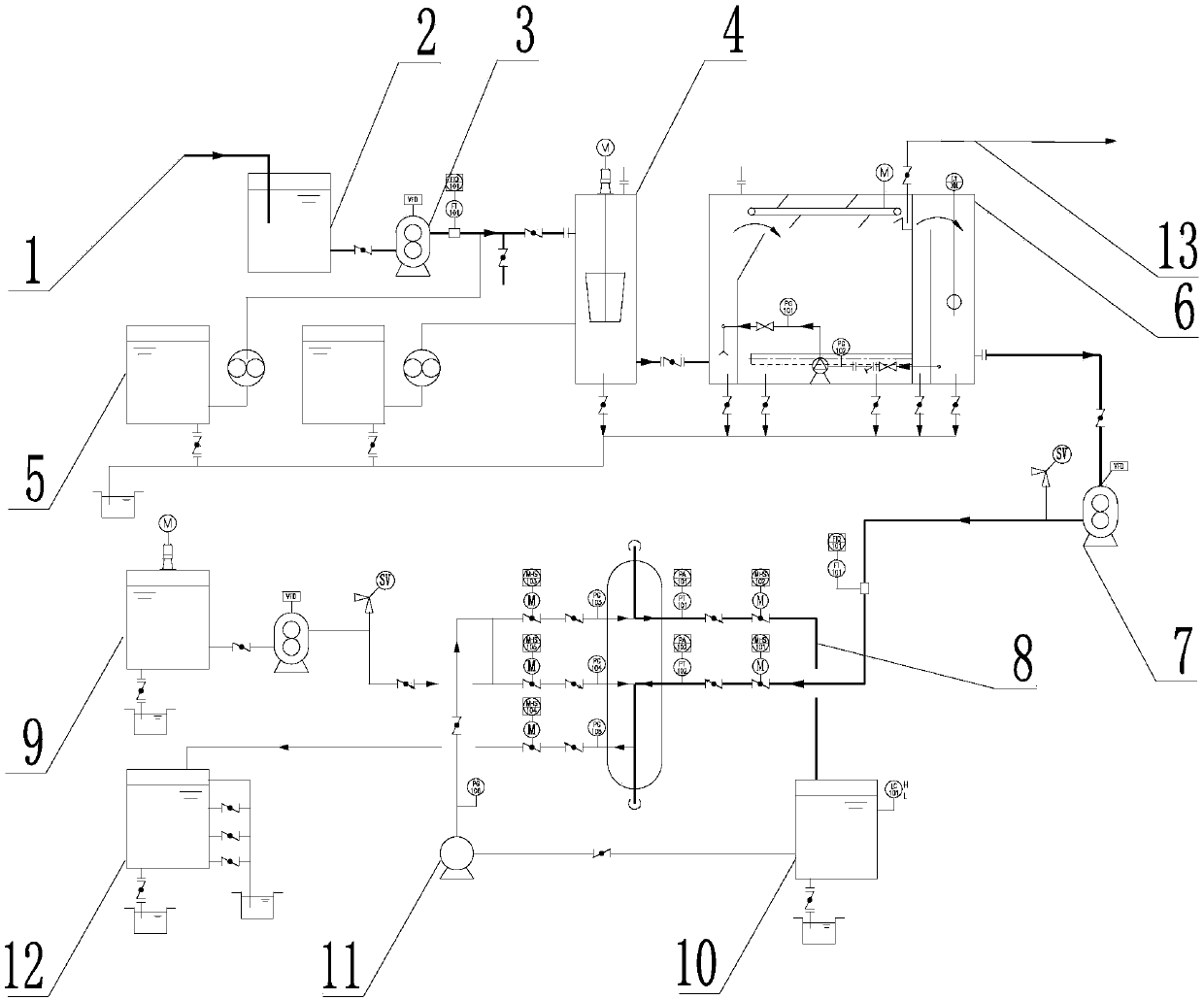

[0030] A pre-coating membrane air flotation integrated device according to the present invention comprises a multi-phase flow dissolved air flotation unit and a pre-coating membrane filtration unit, cooperates with a water inlet settling tank 2, a water production tank 10, and a sludge sludge tank 12 , to form a complete set of sewage treatment device, the multiphase flow dissolved air flotation unit adopts the combination of water inlet pump 3, coagulation stirring device 4, dosing device 5, and multiphase flow dissolved air flotation device 6 to realize the pretreatment of sewage; The pre-coating membrane filtration unit is combined with a booster pump 7, a pre-coating membrane filtration device 8, a membrane powder dosing device 9, and a backwash pump 11, and is automatically controlled by PLC.

[0031] Furthermore, the precoat membrane air flotation integrated device of the present invention integrates the air flotation process and the precoat membrane filtration process to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com