Synthesis and preparation process of 4-phenoxybenzoic acid

A technology of phenoxybenzoic acid and preparation process, which is applied in the directions of oxidative preparation of carboxylic acid, condensation preparation of carbonyl compounds, organic chemistry, etc. The effect of improving the reaction rate and product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

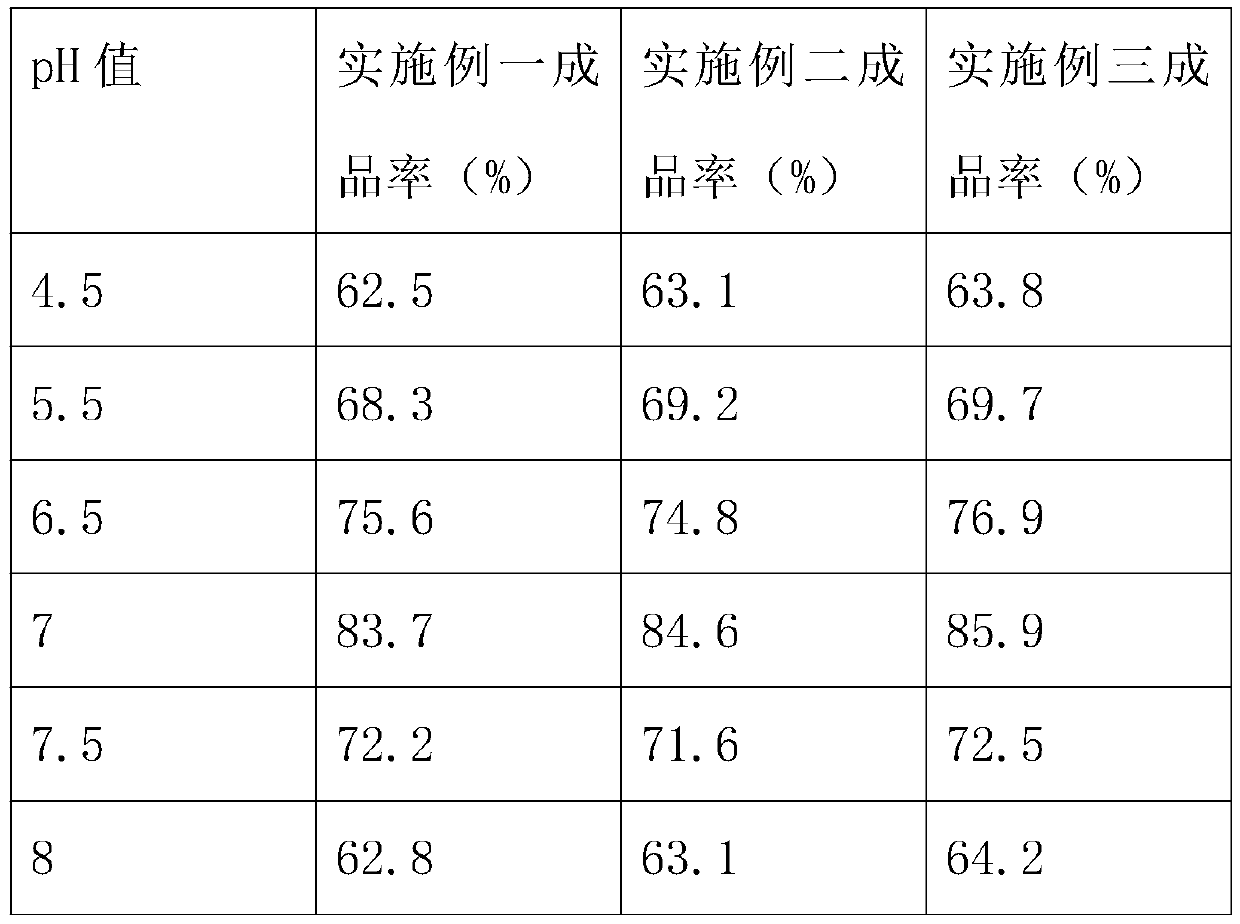

Examples

Embodiment 1

[0022] A kind of synthetic preparation technology of 4-phenoxybenzoic acid, comprises following preparation steps:

[0023] Step 1: Select an appropriate amount of diphenyl ether and dichloromethane into the same reactor, then add anhydrous aluminum trichloride solution to the reactor for stirring, stir for 30 minutes and then add acetic anhydride, heat the reactor and continue stirring , the reactor was continuously heated for 3h, and the stirring rate during the heating process was 25r / min;

[0024] Step 2: Add ice water to the reactor and stir. The ice water and the original solution in the reactor are added in a ratio of 1:3. After stirring, the solution is added to the concentration equipment for concentration treatment. After the treatment is completed, it is passed into the distillation equipment for further processing. Distillation treatment, the distillation temperature is kept at 48 ° C, and the distillation is continued for 35 minutes. The dichloromethane and the or...

Embodiment 2

[0029] A kind of synthetic preparation technology of 4-phenoxybenzoic acid, comprises following preparation steps:

[0030] Step 1: Select an appropriate amount of diphenyl ether and methylene chloride and add them to the same reactor, then add anhydrous aluminum trichloride solution to the reactor for stirring, after stirring for 50 minutes, add acetic anhydride, heat the reactor and continue stirring , the reactor was continuously heated for 5h, and the stirring rate during the heating process was 45r / min;

[0031] Step 2: Add ice water to the reactor and stir. The ice water and the original solution in the reactor are added in a ratio of 1:5. After stirring, the solution is added to the concentration equipment for concentration treatment. After the treatment is completed, it is passed into the distillation equipment for further processing. Distillation treatment, the distillation temperature is kept at 56 ° C, and the distillation is continued for 55 minutes. The dichlorome...

Embodiment 3

[0036] A kind of synthetic preparation technology of 4-phenoxybenzoic acid, comprises following preparation steps:

[0037] Step 1: Select an appropriate amount of diphenyl ether and methylene chloride and add them to the same reactor, then add anhydrous aluminum trichloride solution to the reactor for stirring, stir for 40 minutes and then add acetic anhydride, heat the reactor and continue stirring , the reactor was continuously heated for 4h, and the stirring rate during the heating process was 35r / min;

[0038] Step 2: Add ice water to the reactor and stir. The ice water and the original solution in the reactor are added in a ratio of 1:4. After stirring, the solution is added to the concentration equipment for concentration treatment. After the treatment is completed, it is passed into the distillation equipment for further processing. Distillation treatment, the distillation temperature is kept at 52 ° C, and the distillation is continued for 45 minutes. The dichlorometh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com