Low-radioactivity background waterproof sealing adhesive tape and preparation method thereof

A waterproof sealing, low-radioactive technology, applied in the direction of adhesives, film/sheet adhesives, adhesive additives, etc., can solve the problems of low radioactive background, unsatisfactory, limited application range, etc., and achieve good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

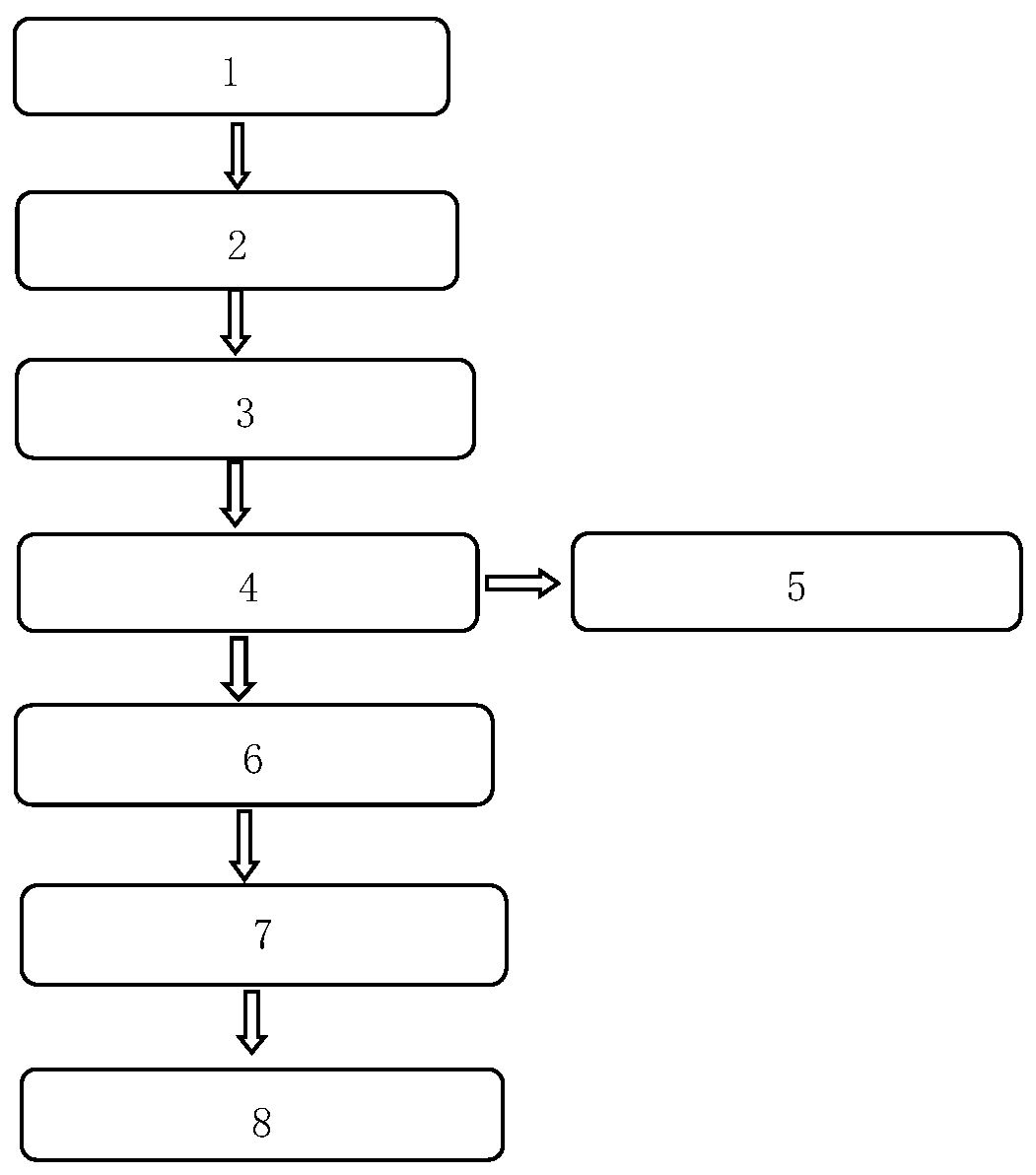

Method used

Image

Examples

Embodiment 1

[0048]In this embodiment, a low-radioactive background waterproof sealing tape is provided, including the following components: 10 parts of butyl rubber, 5 parts of diene rubber, 35 parts of medium molecular weight polyisobutylene, 15 parts of low molecular weight polyisobutylene, hydrophobic filler 20 parts of strong agent, 7.5 parts of hydrophobic filler, 7.5 parts of hydrogenated tackifying resin.

Embodiment 2

[0050] In this embodiment, a low-radioactive background waterproof sealing tape is provided, including the following components: 9 parts of butyl rubber, 4.5 parts of diene rubber, 32 parts of medium molecular weight polyisobutylene, 14 parts of low molecular weight polyisobutylene, hydrophobic filler 18 parts of strong agent, 7 parts of hydrophobic filler, 7 parts of hydrogenated tackifying resin.

Embodiment 3

[0052] In this embodiment, a low-radioactive background waterproof sealing tape is provided, which includes the following components: 11 parts of butyl rubber, 5.5 parts of diene rubber, 38 parts of medium molecular weight polyisobutylene, 16 parts of low molecular weight polyisobutylene, hydrophobic filler 22 parts of strengthening agent, 8 parts of hydrophobic filler, and 8 parts of hydrogenated tackifying resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com