Preparation method for lithium ion battery pole piece and lithium ion battery pole piece

A technology of lithium ion battery and pole piece, applied in the field of lithium ion battery pole piece and its preparation, can solve the problems such as the need to improve the bonding effect and the complex composition of the conductive coating, so as to improve the electrochemical performance and overcome the problems of falling off current collectors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

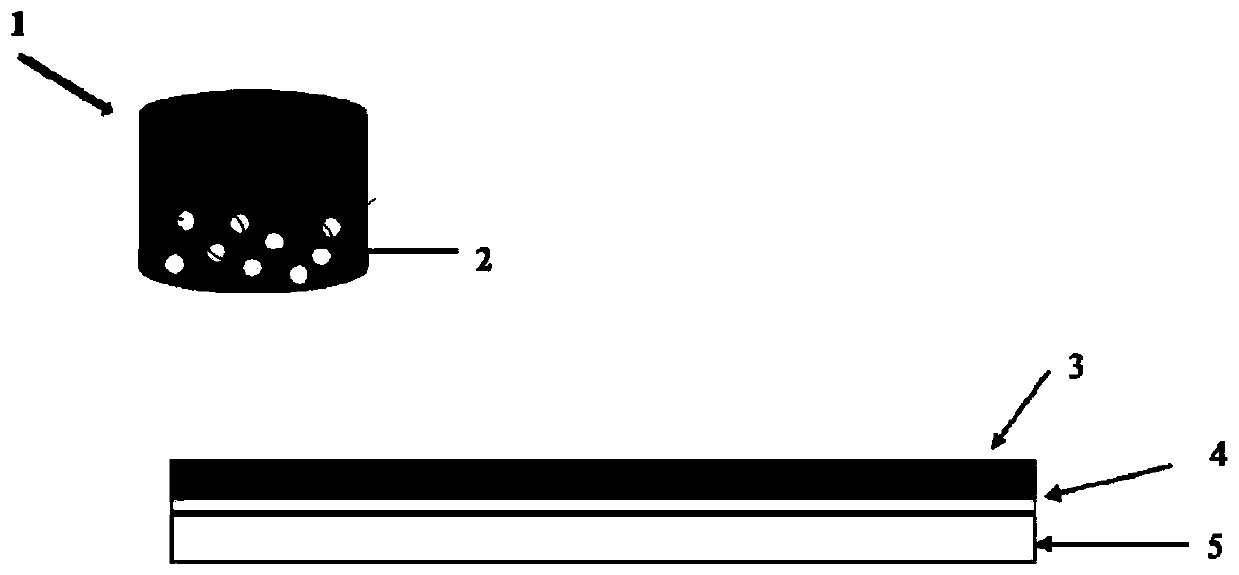

[0027] (1) The preparation concentration is 2mg mL -1 Graphite oxide solution, and coated on common copper foil by spraying, the coating thickness is designed to be 1μm.

[0028] (2) Homogenize 420mAh / g silicon carbon material, SP, CNT, CMC, and SBR according to the mass ratio of 94:1:0.5:2.5:3, and coat it on copper foil to make silicon carbon negative electrode The pole piece, the thickness of the pole piece is 100 μm.

[0029] (3) Test the peel strength of the pole piece.

Embodiment 2

[0034] (1) The preparation concentration is 1.5mg mL -1 Graphite oxide solution, and coated on carbon-coated copper foil by flow coating, the coating thickness is designed to be 3 μm.

[0035] (2) Homogenize 600mAh / g silicon carbon material, SP, VGCF, CMC, and SBR according to the mass ratio of 94:1:0.5:2.5:3, and coat it on copper foil to make silicon carbon negative electrode The pole piece, the thickness of the pole piece is 150 μm.

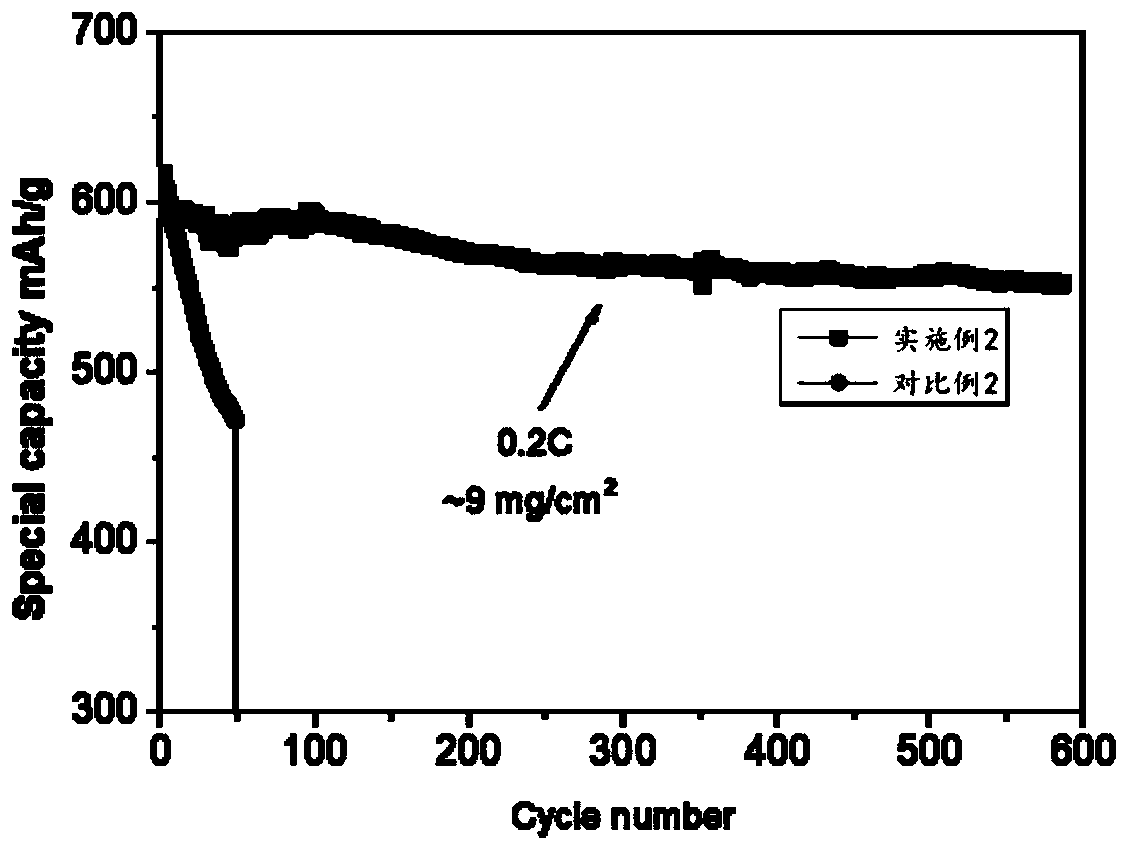

[0036] (3) Assemble the silicon-carbon negative pole piece with the diaphragm and the lithium plate respectively to form a buckle test battery for testing, perform CC charge and discharge on the example at 0.2C, and record relevant performance tests. (See figure 2 the upper line in

Embodiment 3

[0041] (1) The preparation concentration is 1mg mL -1 The graphite oxide solution was sprayed on the porous copper foil by spraying, and the coating thickness was designed to be 2 μm.

[0042] (2) Homogenize 450mAh / g silicon carbon material, SP, CNT, CMC, and SBR according to the mass ratio of 96:1:0.5:1.5:1, and coat it on copper foil to make silicon carbon negative electrode The pole piece, the thickness of the pole piece is 200 μm.

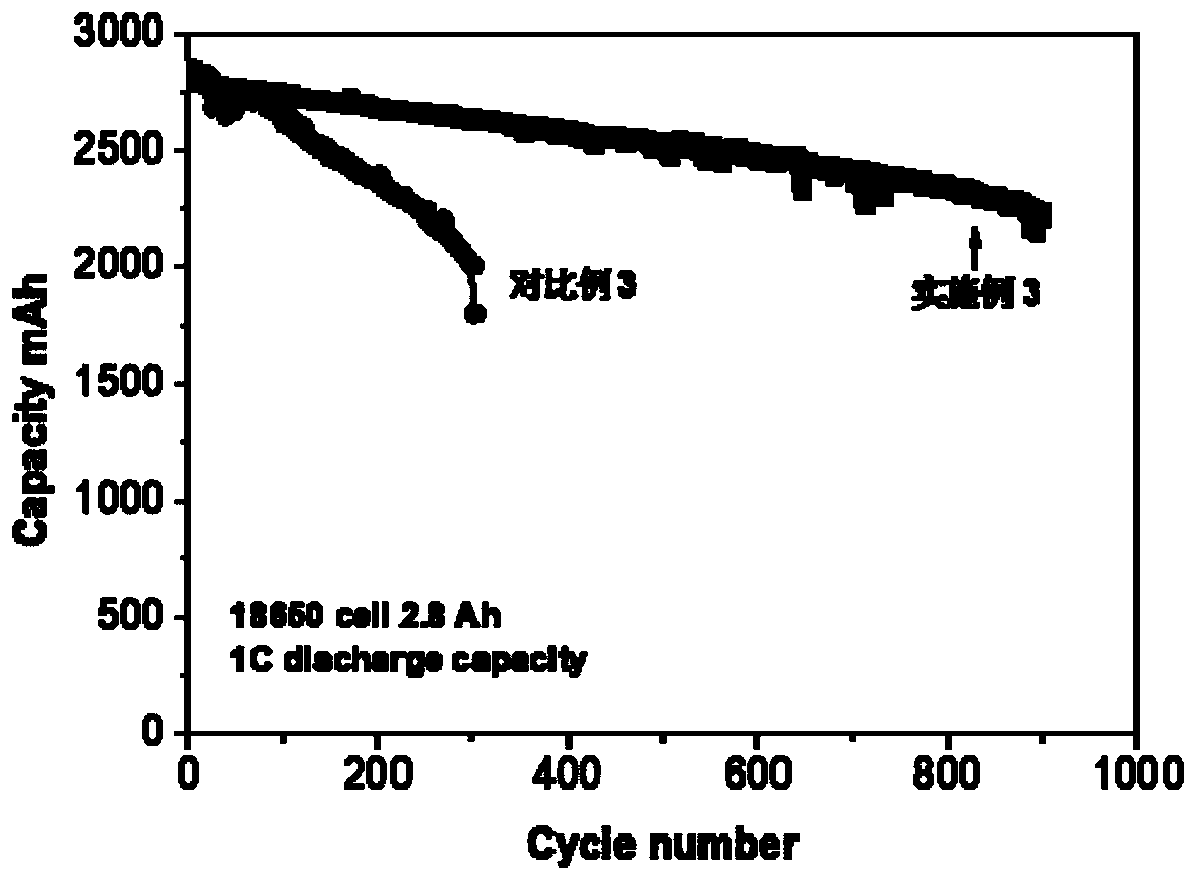

[0043] (3) Assemble the silicon carbon negative pole piece with the diaphragm and the positive pole piece into a battery cell by winding, and then complete the corresponding lithium-ion battery assembly through liquid injection, packaging, standing, formation, aging and other processes.

[0044] (4) Under the environment of 35°C, charge and discharge the example at 1C, constant current constant voltage charging voltage to 4.2V, constant current discharge voltage to 2.75V, record the relevant test performance and take out the electrode sheet af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com