A processing method for heat-not-burn cigarettes with crimped structure

A heat-not-burn and processing technology, which is applied in the fields of tobacco, tobacco processing, and tobacco preparation, can solve the problems of unfavorable drying process in the oven drying section, low smoke release, and inability to solve the problem of arrangement, so as to achieve easy smoke overflow, Facilitate package processing and increase the effect of smoke release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

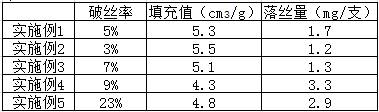

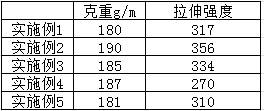

Embodiment 1

[0031] A method for processing heat-not-burn cigarettes with a crimped structure, specifically comprising the following steps:

[0032] S1. Raw material preparation: Prepare the following raw materials in parts by mass: 45 parts of tobacco raw material, 10 parts of atomizing agent, 1 part of solid adhesive, 1 part of tobacco flavor, 0.1 part of graphene nanomaterial, 1 part of fiber, 6 parts of water share;

[0033] The tobacco raw material is a mixture of tobacco leaves, tobacco stems, and shredded tobacco, and the mixing ratio is any ratio. The atomizer is a mixture of propylene glycol and glycerol, and its mass ratio is 1:1. The solid adhesive It is a mixture of xanthan gum and konjac gum with a mass ratio of 1:1, the tobacco flavor is a commercially available tobacco flavor, the graphene nanomaterial is graphene powder, and the fiber is wood pulp fiber.

[0034] S2. Mixing and crushing of dry materials: put the tobacco raw material and solid adhesive into a low-temperatur...

Embodiment 2

[0043] A method for processing heat-not-burn cigarettes with a crimped structure, specifically comprising the following steps:

[0044] S1. Raw material preparation: Prepare the following raw materials in parts by mass: 75 parts of tobacco raw materials, 40 parts of atomizing agent, 10 parts of solid adhesive, 8 parts of tobacco spices, 3 parts of graphene nanomaterials, 8 parts of fiber, 45 parts of water share;

[0045] The tobacco raw material is a mixture of tobacco leaves, tobacco stems, and shredded tobacco, and the mixing ratio is any ratio. The atomizer is a mixture of ethylene glycol and sorbitol, and its mass ratio is 1:1. The solid viscose The agent is a mixture of konjac gum and sodium polyacrylate with a mass ratio of 1:1, the tobacco flavor is commercially available mint flavor, the graphene nanomaterial is graphene nano-acetate fiber, and the fiber tobacco fiber.

[0046] S2. Mixing and crushing of dry materials: put the tobacco raw material and solid adhesive ...

Embodiment 3

[0055] A method for processing heat-not-burn cigarettes with a crimped structure, specifically comprising the following steps:

[0056] S1. Raw material preparation: Prepare the following raw materials in parts by mass: 50 parts of tobacco raw materials, 20 parts of atomizing agent, 5 parts of solid adhesive, 4 parts of tobacco spices, 1 part of graphene nanomaterial, 4 parts of fiber, and 20 parts of water share;

[0057] The tobacco raw material is a mixture of tobacco leaves, tobacco stems, and shredded tobacco, and the mixing ratio is any ratio. The atomizer is a mixture of sorbitol and sorbitol, and its mass ratio is 1:1. The solid viscose The agent is a mixture of chitin and sodium carboxymethyl cellulose with a mass ratio of 1:1, the tobacco flavor is a commercially available tobacco extract, the graphene nanomaterial is graphene oxide, and the fiber tobacco fiber.

[0058] S2. Mixing and crushing of dry materials: put the tobacco raw material and solid adhesive into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com