Iron-manganese composite chromium-removal material and preparation method thereof

A composite material, iron-manganese technology, applied in the direction of chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems of complex development, high process, cost obstacles, etc., to achieve a wide range of pH adaptation, short production cycle, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The iron-manganese composite chromium removal material of the present invention treats heavy metal ion Cr(VI) in water, comprising the following steps:

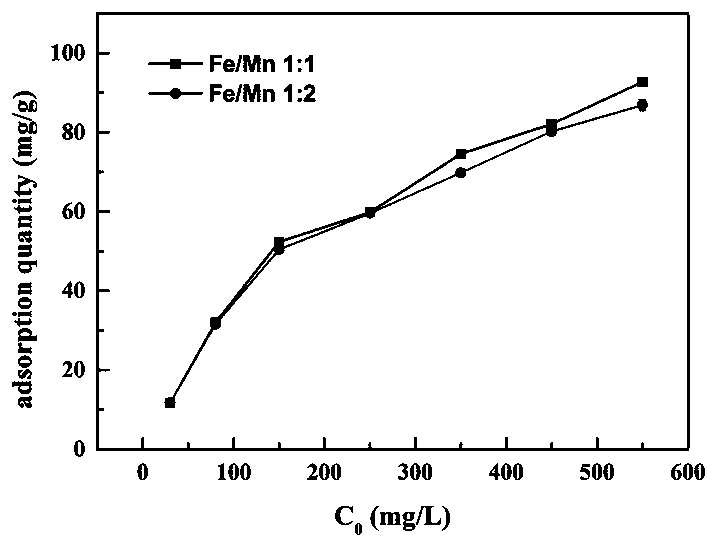

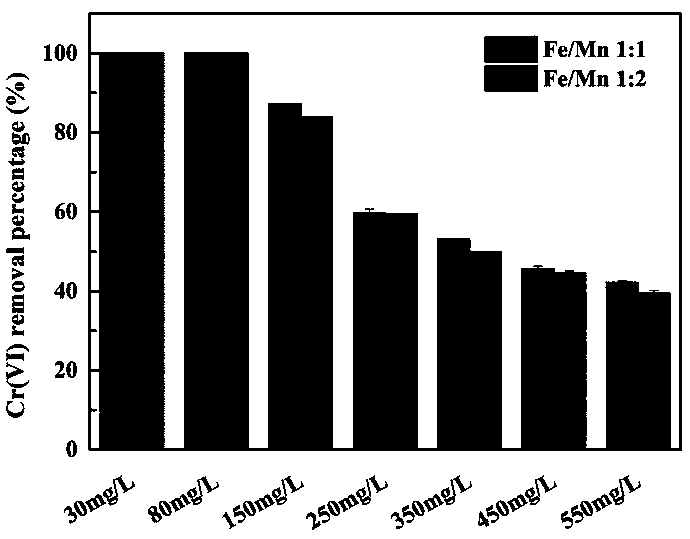

[0022] Preliminary crushing of natural pyrite and rhodochrosite, the crushed particle size is 0.5 cm, and then the minerals are ground into fine powder, passed through a 325 mesh sieve, and then the pyrite and rhodochrosite are ground according to the mass ratio of 1:1 Mix evenly to obtain the iron-manganese mineral complex; place the iron-manganese mineral complex in an atmosphere with hydrogen as the reducing atmosphere and argon as the protective gas at 500°C for 2 hours, the control gas flow rate is 150 mL / min, and the heating rate is 20 °C / min. The temperature is naturally lowered, and the roasted powdered composite material is collected to obtain the iron-manganese composite material for chromium removal. Take 0.05g of the composite material, respectively place the initial concentration of 30 / 80 / 150 / 250 / 350 / 450 / ...

Embodiment 2

[0024] The iron-manganese composite chromium removal material of the present invention treats heavy metal ion Cr(VI) in water, comprising the following steps:

[0025] The natural pyrite and rhodochrosite are preliminarily crushed, the crushed particle size is 0.5cm, and then the minerals are ground into fine powder, passed through a 325 mesh sieve, and then the pyrite and rhodochrosite are ground according to the mass ratio of 1:2 Mix evenly to obtain the iron-manganese mineral complex; place the iron-manganese mineral complex in an atmosphere with hydrogen as the reducing atmosphere and argon as the protective gas at 500°C for 2 hours, the control gas flow rate is 150 mL / min, and the heating rate is 20 °C / min. During the natural cooling process, the roasted powdered composite material is collected to obtain the iron-manganese composite material for chromium removal. Take 0.05g of the composite material, respectively place the initial concentration of 30 / 80 / 150 / 250 / 350 / 450 / 5...

Embodiment 3

[0027] The iron-manganese composite chromium removal material of the present invention treats heavy metal ion Cr(VI) in soil, comprising the following steps:

[0028] Preliminary crushing of natural pyrite and rhodochrosite, the crushed particle size is 0.5 cm, and then the minerals are ground into fine powder, passed through a 325 mesh sieve, and then the pyrite and rhodochrosite are ground according to the mass ratio of 1:1 Mix evenly to obtain the iron-manganese mineral complex; place the iron-manganese mineral complex in an atmosphere with hydrogen as the reducing atmosphere and argon as the protective gas at 500°C for 2 hours, the control gas flow rate is 150 mL / min, and the heating rate is 20 °C / min. During the natural cooling process, the roasted powdered composite material is collected to obtain the iron-manganese composite material for chromium removal. Add a concentration of 2.5g / kg evenly into 150mg / kg of Cr(VI)-contaminated soil samples, and keep the soil at a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com