Preparation method of modified cation exchange membrane

A cation exchange membrane and modification technology, which is applied in the field of preparation of modified cation exchange membranes, can solve the problems of low environmental effects, low selectivity, limited application, etc., achieve good selective separation performance, simple preparation process, non-toxic and environmentally friendly preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The homogeneous Type-I commercial cation exchange membrane produced by Japan Fujifilm was used as the base membrane. Wash the impurities on the surface of the original commercial membrane with deionized water, and then soak the membrane in 0.1M Na 2 SO 4 In solution for 24 hours before use.

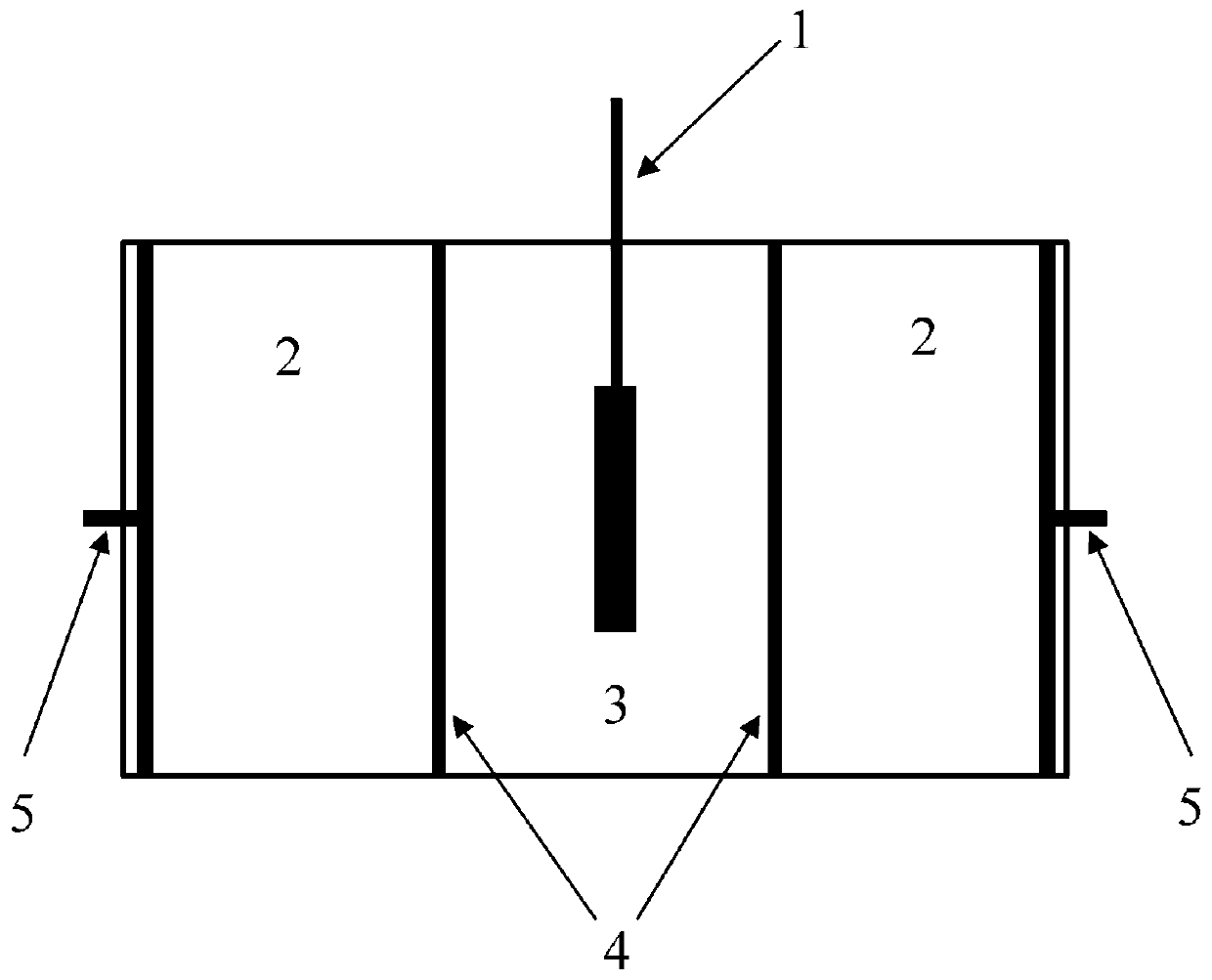

[0050] AC electric field film surface assembly system such as figure 1 As shown, two base films after the above pretreatment are vertically fixed on the film placement position of the device, and the surfaces to be modified are all facing the feed liquid chamber. The effective area of one film is 28.26cm 2 .

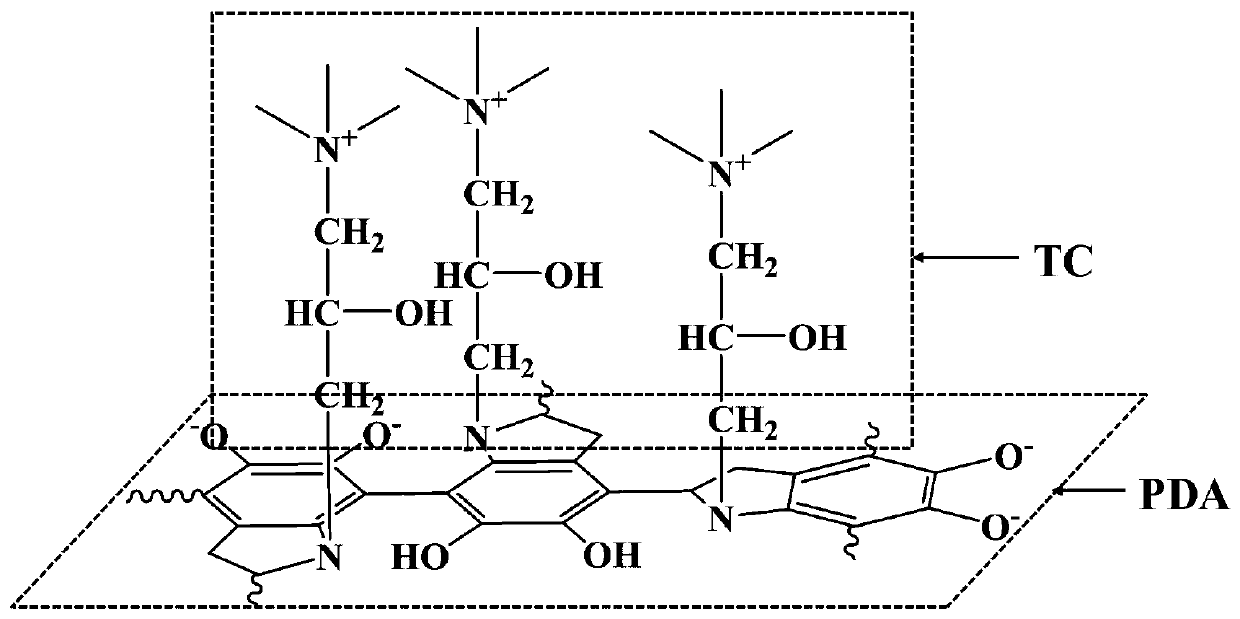

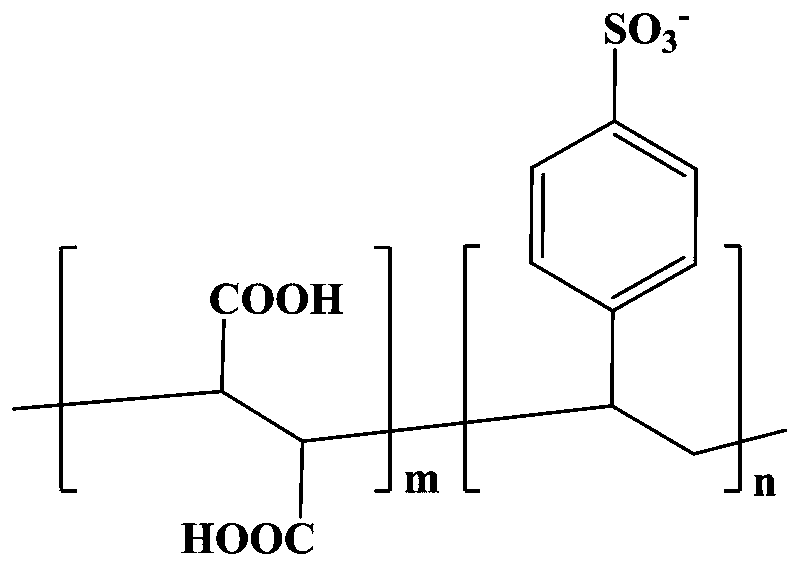

[0051] Weigh 0.3g dopamine and 0.165g Na 2 SO 4 And added to 150mL Tris-HCl (pH = 8.5) and CuSO 4 The mixed solution (its configuration method is that 1M hydrochloric acid solution adjusts the Tris-HCl damping fluid of 10mM, makes its pH value 8.8, is then configured as the mixed solution of 5mM copper sulfate) and stirs rapidly to make dopamine and lithium sulfate di...

Embodiment 2

[0056] The preparation steps of the special cation exchange membrane were the same as in Example 1, and 5.5 modified double-layer special cation exchange membranes were prepared.

Embodiment 3

[0058] The selective permeability measuring device of the modified cation exchange membrane prepared by the homogeneous Type-I type commercial cation exchange membrane produced by Japan Fujifilm Company and embodiment 1 and embodiment 2 is as Figure 4 , the membrane is placed in the electrodialysis device (anion exchange membrane selects the homogeneous Type-I type anion exchange membrane produced by Japan Fujifilm Company, and the effective membrane area is 20cm 2 ) for testing, the middle two compartments are fed with LiCl and MgCl 2 Mixed solution (LiCl and MgCl 2 The concentration is 50mM), the electrolyte in the electrode chamber is 500mL 0.5M NaCl solution, at 7.65mA / cm 2 Operate under the current density, pipette the feed liquid in the desalination chamber every 10min, and measure its Li by cation chromatography + and Mg 2+ Concentration, a total of 80min. The change of the concentration of a divalent anion of the film over time is measured, and the results are as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com