Novel method for efficiently synthesizing dibenzoylmethane

A technology for dibenzoylmethane and methyl benzoate, which is applied in the field of novel and efficient synthesis of dibenzoylmethane, can solve the problems of high cost of raw materials, many by-products, low yield of dibenzoylmethane, etc., and achieves condensation The effect of short reaction period, less by-products and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

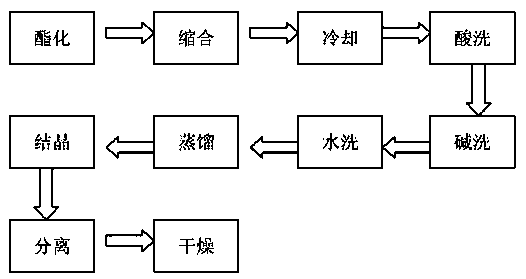

Method used

Image

Examples

Embodiment 1

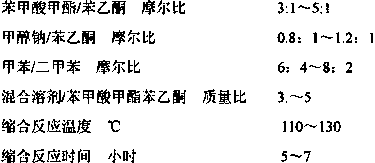

[0087] Prepare dibenzoylmethane of the present invention according to the following steps

[0088] ① . Synthesis of methyl benzoate

[0089] Using benzoic acid and methanol as raw materials, using sulfuric acid as a catalyst, it is prepared by esterification and distillation

[0090] a. Esterification process conditions

[0091] Benzoic acid / methanol molar ratio 1:4 ~ 1:6

[0092] The esterification reaction temperature is 70-80°C

[0093] Response time hours 4 to 5

[0094] Put 366g of benzoic acid and 384g of methanol into a three-necked flask, raise the temperature to 70°C-80°C, and wait until the benzoic acid is completely dissolved

[0095] After thawing, concentrated sulfuric acid was added dropwise, and the reaction was refluxed for 4-5 hours. After the reaction is completed, distill and recover the residual methanol to obtain the crude product.

[0096] b. Esterification solution treatment

[0097] The esterification solution from step a is washed with water, al...

Embodiment 2~ Embodiment 5

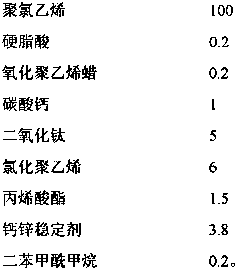

[0127] According to the method and steps of Example 1, the stearoylbenzoylmethane product of the present invention is prepared according to the formula in Table 1

[0128] Table 1

[0129]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com