Novel high-speed high-strength paper tube adhesive and preparation method thereof

A paper tube glue, high-speed technology, applied in the direction of adhesive types, non-polymer adhesive additives, adhesive additives, etc., can solve the problem that paper tube glue cannot effectively remove formaldehyde, low viscosity of glue, and product quality. Non-compliance and other problems, to achieve the effect of high speed, high hardness of products, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

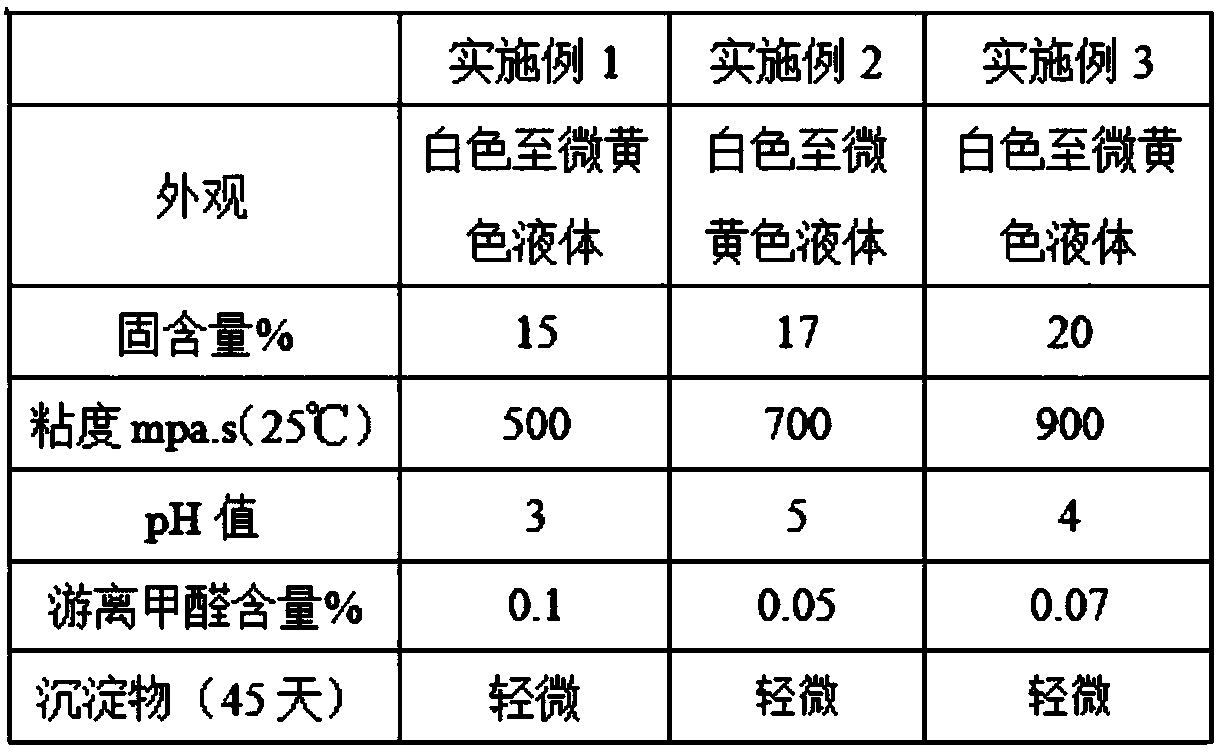

Examples

Embodiment 1

[0024] A preparation method of a new type of high-speed high-strength paper tube glue, the raw material components of the paper tube glue are: 7% kaolin, 7% polyvinyl alcohol, 0.2% sodium hexametaphosphate, 1.5% formaldehyde, corn starch Solution 0.1%, boric acid+borax aqueous solution 0.5%, defoamer 0.3%, antiseptic bactericide 0.3%, water 83.1%; comprise the following steps:

[0025] Step 1: First add water accounting for 40% of the above remaining water quality into the reaction kettle, then add kaolin, polyvinyl alcohol, and dispersant in the above mass ratio under stirring, continue stirring for 20 minutes, then raise the temperature to 90°C, and keep warm 40min obtains mixed solution;

[0026] Step 2: Add hydrochloric acid to the mixed solution obtained in the above step 1 to adjust the pH value to 2.0, then add the above mass ratio of formaldehyde, react for 40 minutes, observe the reaction situation and add 0.3% ammonia water immediately after the phenomenon of glue se...

Embodiment 2

[0029] A method for preparing a novel high-speed, high-strength paper tube glue. The raw material components of the paper tube glue are: kaolin 9%, polyvinyl alcohol 8%, sodium hexametaphosphate 0.1%, formaldehyde 1%, corn starch Solution 0.3%, boric acid+borax aqueous solution 0.3%, defoamer 0.1%, antiseptic bactericide 0.1%, water 81.1%; comprise the following steps:

[0030] Step 1: First add water accounting for 41% of the above remaining water quality into the reaction kettle, then add kaolin, polyvinyl alcohol, and dispersant in the above mass ratio under stirring, continue stirring for 30 minutes, then raise the temperature to 95°C, and keep warm 60min obtains mixed solution;

[0031] Step 2: Add hydrochloric acid to the mixed solution obtained in the above step 1 to adjust the pH value to 1.8, then add the above mass ratio of formaldehyde, react for 60 minutes, observe the reaction situation and add 0.5% ammonia water immediately after the phenomenon of glue separation...

Embodiment 3

[0034] A method for preparing a novel high-speed and high-strength paper tube glue. The raw material components of the paper tube glue are: 8% kaolin, 9% polyvinyl alcohol, 0.15% sodium hexametaphosphate, 1.2% formaldehyde, corn starch Solution 0.2%, boric acid+borax aqueous solution 0.4%, defoamer 0.2%, antiseptic bactericide 0.2%, water 80.65%; comprise the following steps:

[0035] Step 1: First add water accounting for 42% of the above remaining water quality into the reaction kettle, then add kaolin, polyvinyl alcohol, and dispersant in the above mass ratio under stirring, continue stirring for 26 minutes, then raise the temperature to 93°C, and keep warm 50min obtains mixed solution;

[0036] Step 2: Add hydrochloric acid to the mixed solution obtained in the above step 1 to adjust the pH value to 1.9, then add the formaldehyde in the above mass ratio, and react for 55 minutes. Observe the reaction situation and add 0.4% ammonia water immediately after glue separation oc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com