Method for preparing banana resistant starch

A technology of banana resistant starch and banana, applied in the direction of fermentation and the like, can solve the problems of low utilization rate of banana, low solubility of banana resistant starch, etc., and achieve the effects of solving low utilization rate, increasing added value, and promoting development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

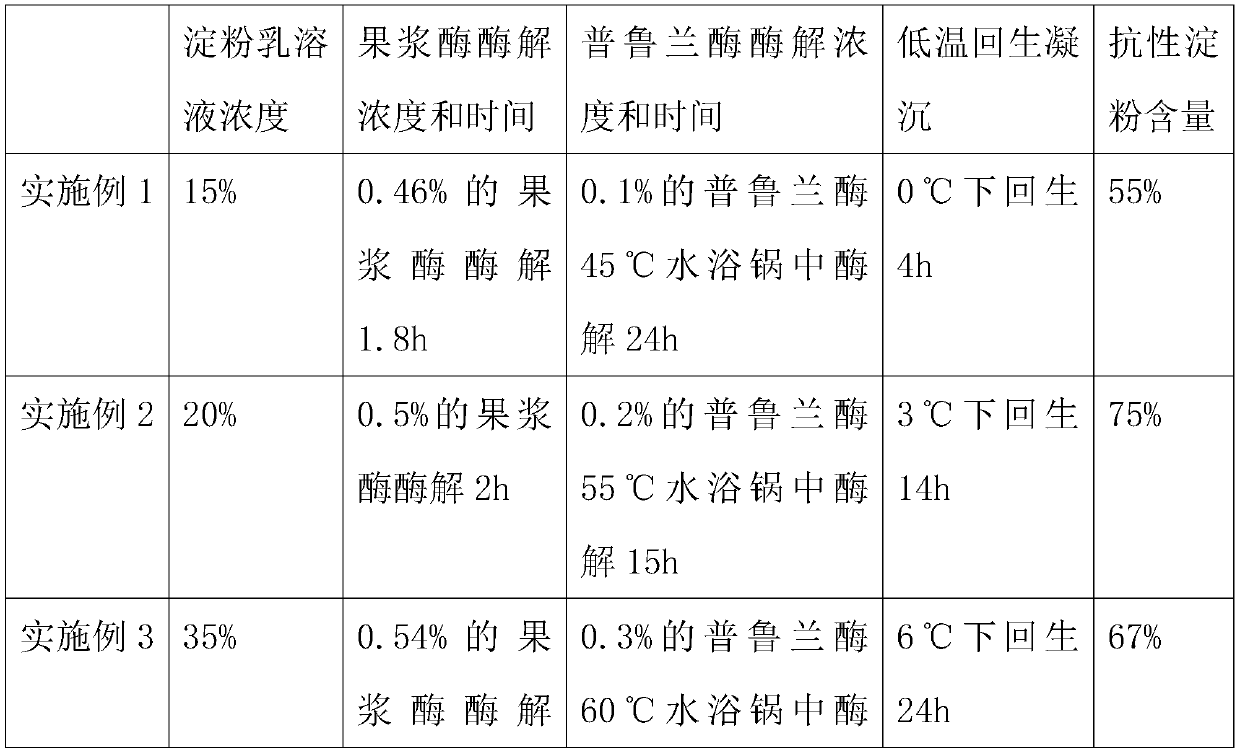

Embodiment 1

[0027] The invention provides a method for preparing banana resistant starch, comprising the following processing steps:

[0028] S1, preparation materials: prepare completely green bananas (may be 1st level ripeness Baodao banana or other types of bananas whose surface is full green), peel and get its pulp, then cut into pieces, get its pulp, roll and stir until Pasty;

[0029] The extraction of S2, green banana starch comprises the following extraction steps:

[0030] S2.1: Add 0.46% fruit pulp enzyme to the mushy banana, adjust the pH value to 5.2 (tested by acidity meter), and use a water bath shaker to carry out enzymatic hydrolysis;

[0031] S2.2: After 1.8 hours of enzymatic hydrolysis, use a centrifuge for centrifugation, and the centrifuge speed is 5000r / min, and the centrifugation time is 8min. Remove the supernatant, then wash with distilled water, and repeat the centrifugation 3 times;

[0032] S2.3: Finally, dry the solid components with hot air at 55°C for 13 h...

Embodiment 2

[0038] The invention provides a method for preparing banana resistant starch, comprising the following processing steps:

[0039] S1, preparation materials: prepare completely green bananas (may be 1st level ripeness Baodao banana or other types of bananas whose surface is full green), peel and get its pulp, then cut into pieces, get its pulp, roll and stir until Pasty;

[0040] The extraction of S2, green banana starch comprises the following extraction steps:

[0041] S2.1: Add 0.5% fruit pulp enzyme to the mushy banana, adjust the pH value to 5 (detected by acidity meter), and use a water bath shaker to carry out enzymatic hydrolysis;

[0042] S2.2: After 2 hours of enzymatic hydrolysis, use a centrifuge for centrifugation, and the centrifuge speed is 5000r / min, and the centrifugation time is 10min. Remove the supernatant, then wash with distilled water, and repeat the centrifugation 3 times;

[0043] S2.3: Finally, dry the solid components with hot air at 60°C for 12 hou...

Embodiment 3

[0049] The invention provides a method for preparing banana resistant starch, comprising the following processing steps:

[0050] S1, preparation materials: prepare completely green bananas (may be 1st level ripeness Baodao banana or other types of bananas whose surface is full green), peel and get its pulp, then cut into pieces, get its pulp, roll and stir until Pasty;

[0051] The extraction of S2, green banana starch comprises the following extraction steps:

[0052] S2.1: Add 0.54% fruit pulp enzyme to the mushy banana, adjust the pH value to 4.8 (tested by acidity meter), and use a water bath shaker to carry out enzymatic hydrolysis;

[0053] S2.2: After 2.2 hours of enzymatic hydrolysis, use a centrifuge for centrifugation, and the centrifuge speed is 5000r / min, and the centrifugation time is 12min. Remove the supernatant, then wash with distilled water, and repeat the centrifugation 3 times;

[0054] S2.3: Finally, dry the solid components with hot air at 65°C for 11 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com