An optical power splitter based on three-coupled waveguides with transverse magnetic mode cutoff and transverse electric mode equalization

A technology of coupling waveguide and optical power splitter, applied in the field of integrated optics, can solve the problems of high insertion loss, high ohmic loss, unfavorable PIC dense integration, etc., and achieve the effect of low insertion loss, high ohmic loss and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

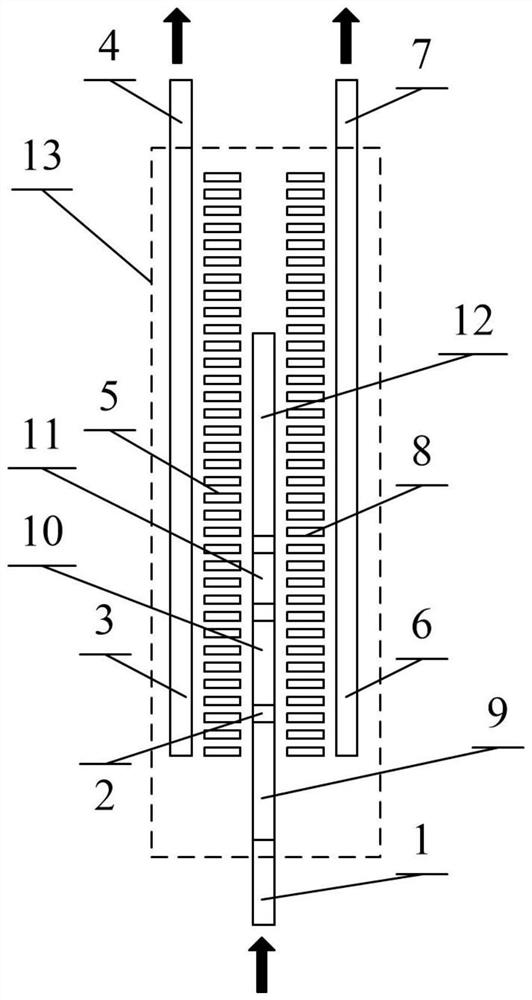

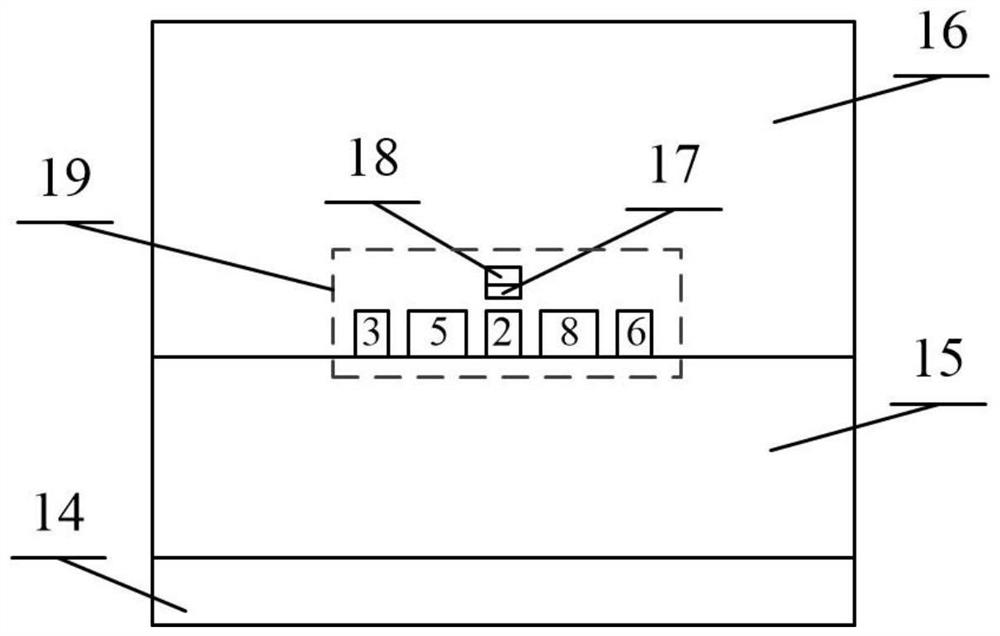

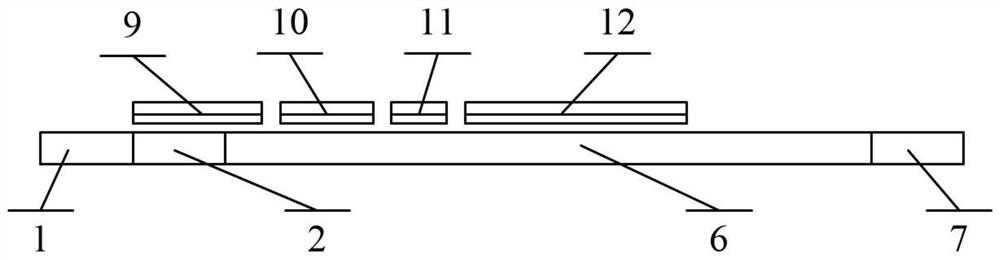

[0029] like figure 1 and image 3 As shown, the optical power splitter consists of a silicon-based substrate 14, a buried oxide layer 15, an optical power sub-component 19 and an upper cladding layer 16 from bottom to top, wherein the buried oxide layer 15 is grown on the upper surface of the silicon-based substrate 14 , the upper cladding layer 16 covers the upper surface of the buried oxide layer 15 , and the optical power component 19 grows horizontally on the upper surface of the buried oxide layer 15 and is covered by the upper cladding layer 16 .

[0030]The optical power component 19 includes a lower layer input channel 1, a lower layer middle channel through channel 2, a lower layer left channel through channel 3, a lower layer left output channel 4, a lower layer left subwavelength grating channel 5, a lower layer right channel through channel 6, and a lower layer right channel Output channel 7, lower right sub-wavelength grating channel 8, upper middle direct channe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com