Method for quickly identifying pattern included angle of monocrystalline silicon wafer

A technology of single crystal silicon wafers and identification methods, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of cumbersome measurement, long working hours, and low efficiency, and achieve the effect of simple and effective methods and high identification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to understand the purpose, technical solutions and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

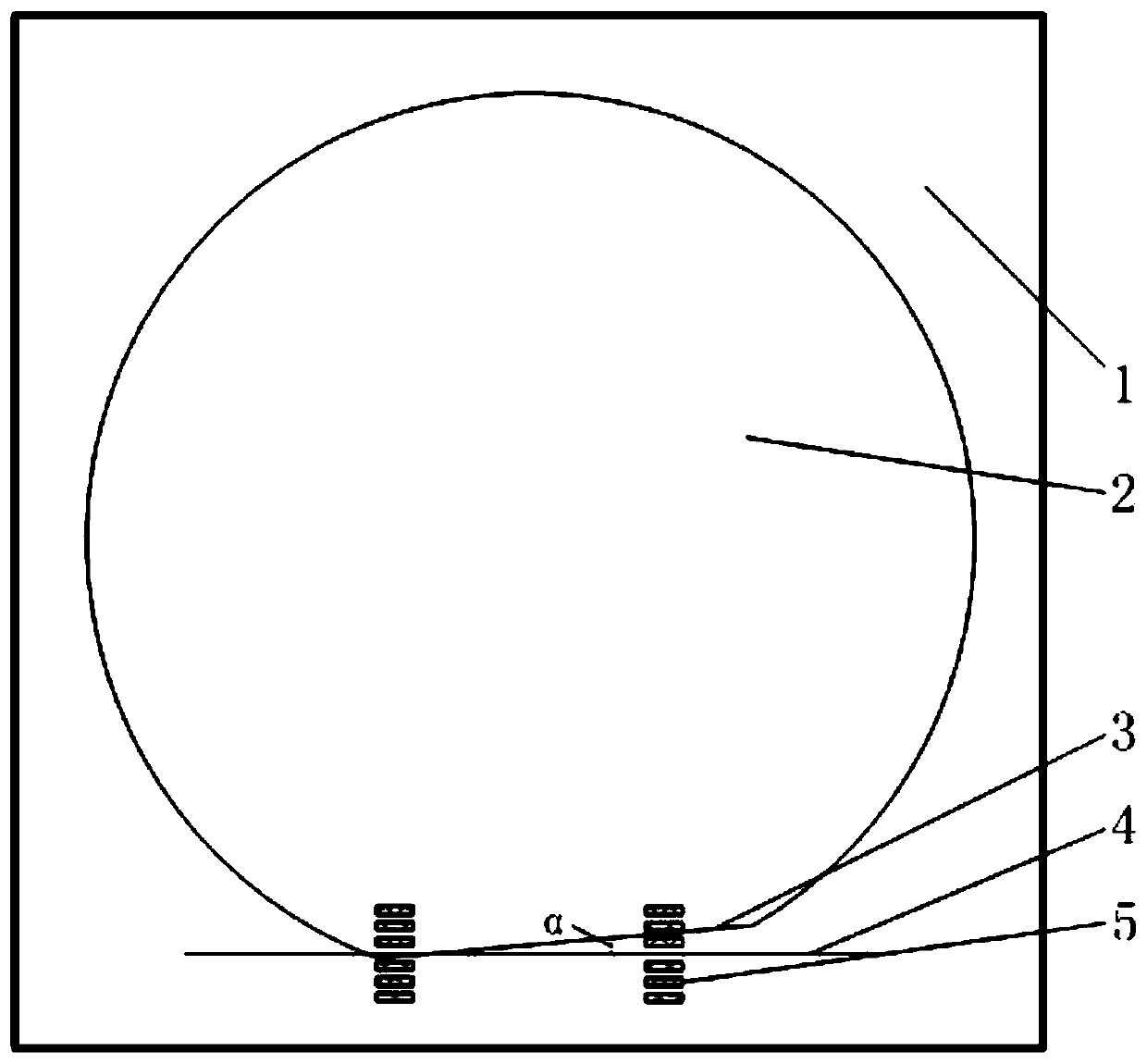

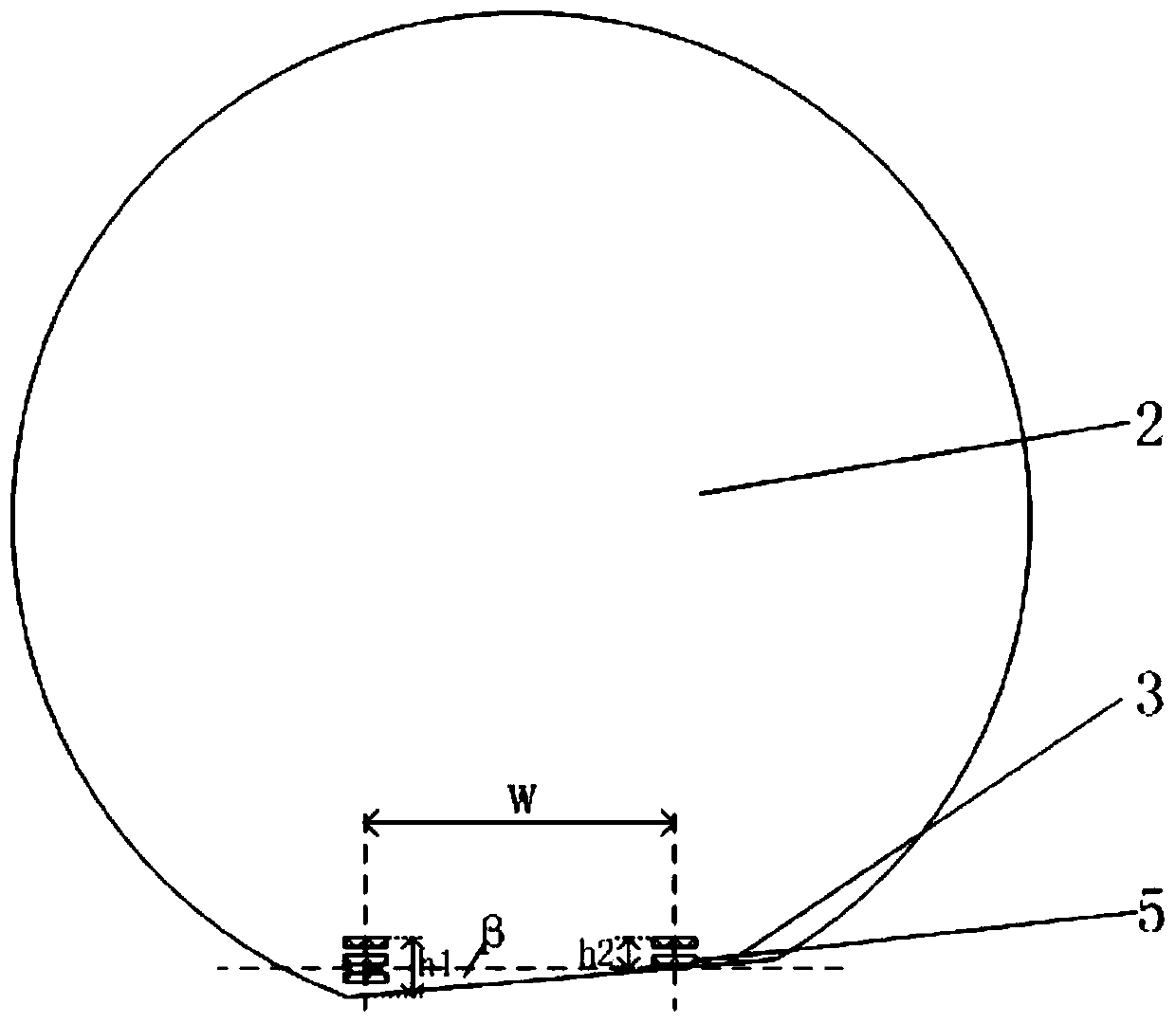

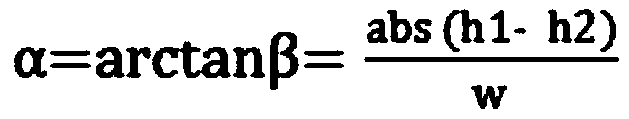

[0010] The invention provides a method for quickly identifying the included angle of a single crystal silicon chip pattern. figure 1 It is a schematic diagram of the alignment of the method for quickly identifying the included angle of a single crystal silicon wafer pattern according to the present invention. In the method, when designing the photoresist plate, two equidistant one-dimensional array identification scales 5 with a certain distance are set in the vertical direction of the alignment line 4 of the photoresist plate 1 . Then in the photolithography process, align the main reference edge of the silicon wafer with the alignment line 4 on the photoresist plate 1, and use the photolithography process to transpose the identificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com