Ocean engineering anticorrosion and anti-cracking mortar, and preparation method and use method thereof

A marine engineering and mortar technology, which is applied in the field of marine engineering anti-corrosion and anti-cracking mortar, can solve the problems of concrete chloride salt erosion, etc., and achieve the effects of improving comprehensive durability, low cost, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

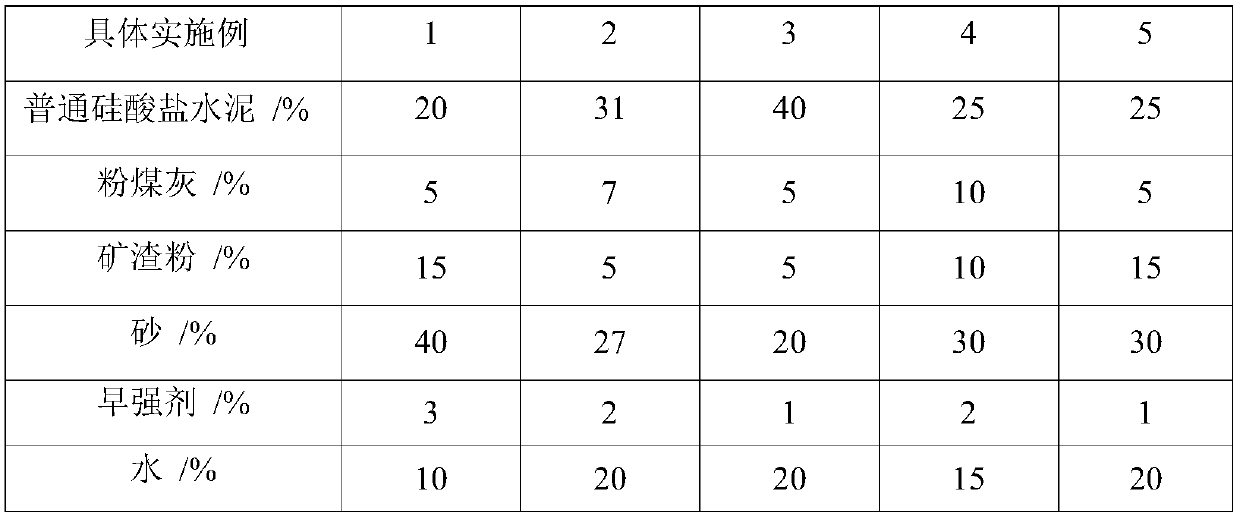

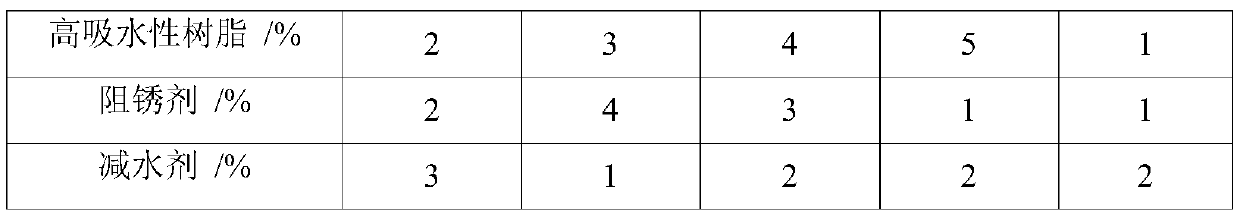

[0019] The anti-corrosion and anti-cracking mortar for ocean engineering provided by the present invention comprises the following raw material components in the mass percentage relationship: 20-40% of ordinary Portland cement; 5-10% of fly ash; 5-15% of slag powder; 20% of sand -40%; early strength agent 1-3%; water 10-20%; superabsorbent resin 1-5%; rust inhibitor 1-4%; water reducing agent 1-3%.

[0020] In the present invention, the grade of the ordinary Portland cement is 42.5 grade or above, and the chloride ion content is ≤0.1%. The CaO content in the fly ash is more than 10%, the fineness is ≤ secondary ash, and the chloride ion content is ≤ 0.1%. The slag powder is granulated blast furnace slag powder, the activity index is greater than or equal to S95 grade ash, and the chloride ion content is less than or equal to 0.1%. The sand is any one of river sand, sea sand and machine-made sand, 1.5≤fineness modulus≤3.0, and chloride ion content≤0.1%. The early strengthenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com