Novel high-purity acetylene purification production system and technological process thereof

A production system and acetylene generator technology, which is applied in the purification/separation of hydrocarbons, chemical change purification/separation, organic chemistry, etc., can solve the problem of purification purity not meeting the requirements of customers, high cost, and achieve impurity removal. The effect of enhancing the effect, increasing the contact time, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

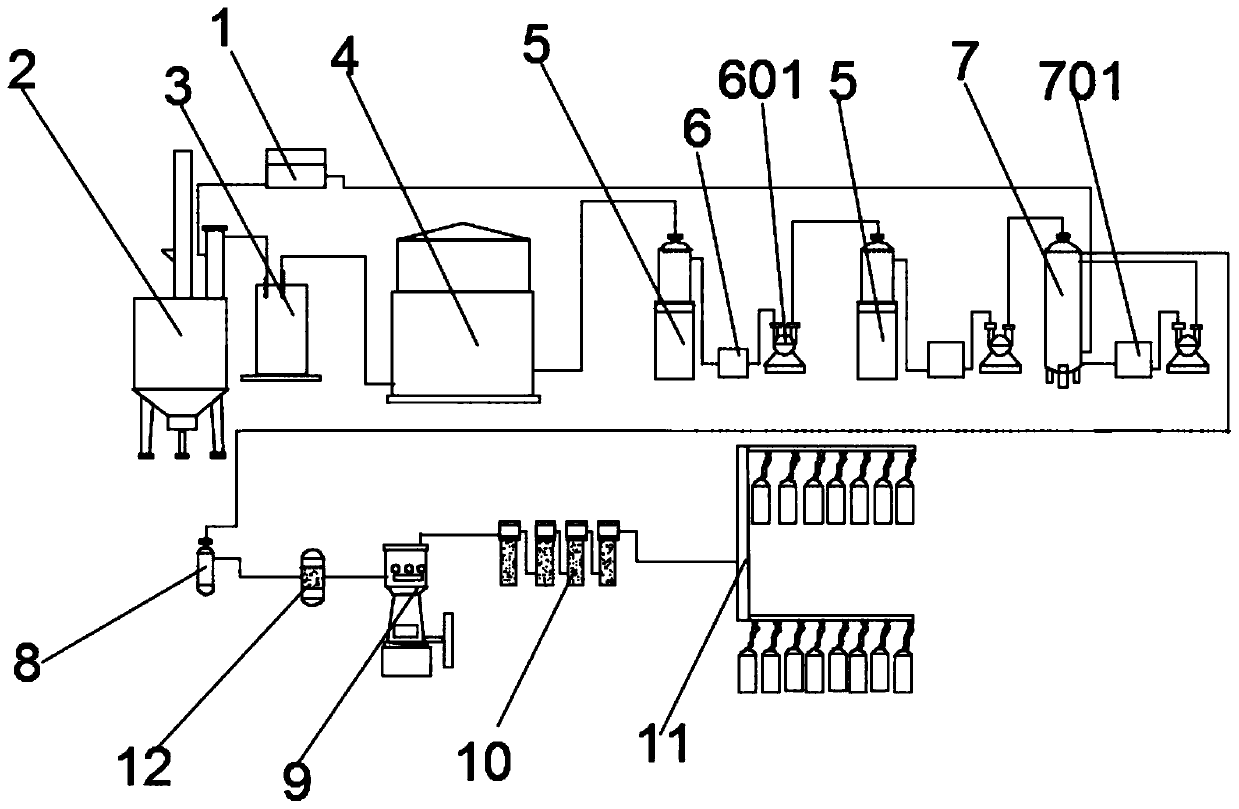

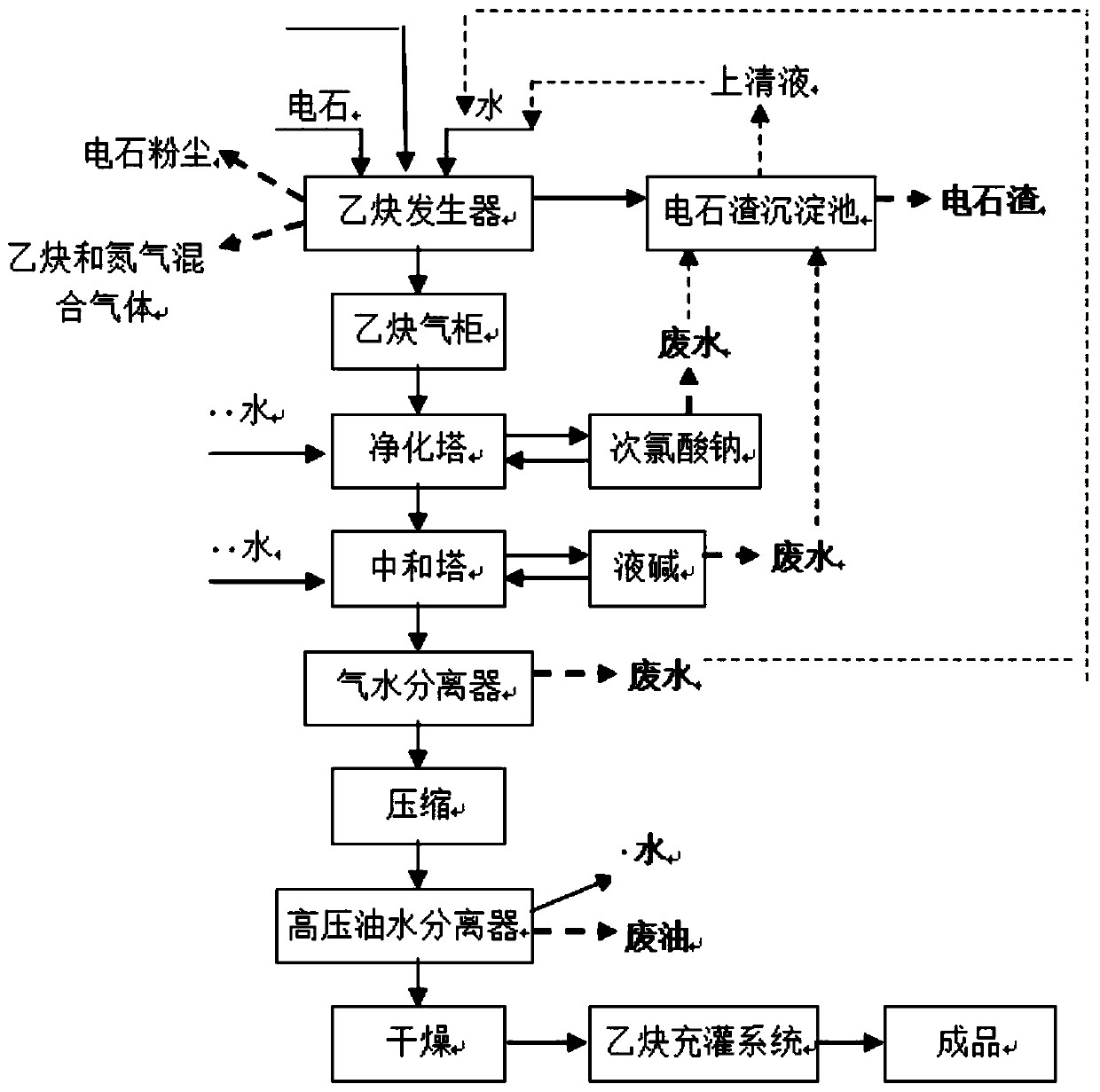

[0037] Such as Figure 1 to Figure 2As shown, a new type of high-purity acetylene purification production system includes calcium carbide slag sedimentation tank, acetylene generator, acetylene gas cabinet, safety water seal, purification tower, purification tower water tank, neutralization tower, neutralization tower water tank, Gas-water separator, low-temperature dryer, compressor, high-pressure oil-water separator drying box and acetylene filling system, the height of the packing layer of the purification tower is 7-11m, and the purification tower includes the first purification tower and the second purification tower , the second purification tower is connected to the neutralization tower.

[0038] The specific steps for the purification and production of acetylene gas by using the above-mentioned new high-purity acetylene purification production system are as follows:

[0039] (1) The process flow of acetylene gas: put a certain amount of water in the acetylene generato...

Embodiment 2

[0044] Such as Figure 1 to Figure 2 As shown, in order to make the present invention have a better purification effect in the purification tower 5, this embodiment has made further improvements on the basis of Embodiment 1, specifically: each of the purification towers 5 is provided with 6 spray heads 503, a Pall ring is added at the spray head 503 in the purification tower 5.

Embodiment 3

[0046] Such as Figure 1 to Figure 2 Shown in order to make the consumption cost of sodium hypochlorite solution of the present invention, present embodiment has done further improvement on the basis of embodiment 2, specifically: described purification tower 5 water tanks are two, and described two purification towers 5 all connect A water tank and a circulating water pump 601 connected with the water tank are provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com