3D printing method for selective laser curing metal

A 3D printing and laser selection technology, applied in the direction of process efficiency improvement, additive manufacturing, additive processing, etc., can solve the problems of low forming precision and low printing efficiency, achieve high forming precision, fast forming speed, and ensure high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0032] The steps of preparing iron-based alloy parts are as follows:

[0033] (1) Equipped with a photosensitive solvent: acryloylmorpholine (ACMO, with a purity of 98%) and 2,4,6-trimethylbenzoyl-diphenyl (Omnirad TPO) were prepared according to a mass ratio of 95:5 For comparison, add the two together and stir evenly with a glass rod to fully dissolve TPO into ACMO, prepare it as a photosensitive solvent and pour it into an aluminum bottle for later use;

[0034] (2) Preparation of photosensitive slurry: measure 7ml of photosensitive solvent, place it under a digital display electric stirrer to stir and mix at a speed of 800rpm / min, weigh 100g of iron-based alloy 10V powder (D 50 = 30 μm), gradually add the powder into the photosensitive solvent, and after the powder is completely added, increase the rotating speed to 1600rpm / min and stir for 30 minutes to obtain a uniform photosensitive slurry without aggregates, and the solid phase volume fraction is 65.5%. Adding 3wt.% o...

Embodiment example 2

[0040] The steps of preparing titanium alloy parts are as follows:

[0041] (1) Pour 15g of acryloylmorpholine (ACMO, with a purity of 98%) into a beaker, then weigh 0.75g of 2,4,6-trimethylbenzoyl-diphenyl (Omnirad TPO) and pour Pour into a beaker and stir until fully dissolved for later use;

[0042] (2) Weigh a certain amount of titanium alloy TC4 powder (particle size 50 μm), add the prepared photosensitive solvent to make its solid content 63vol.%, and add 0.5wt.% stearic acid to improve fluidity, pour Mixing is carried out in the mixing tank of the vacuum planetary ball mill, the ball-to-material ratio is 1:1, the ball milling speed is 100rpm / min, the ball milling time is 30min, and the slurry after ball milling is taken out for use;

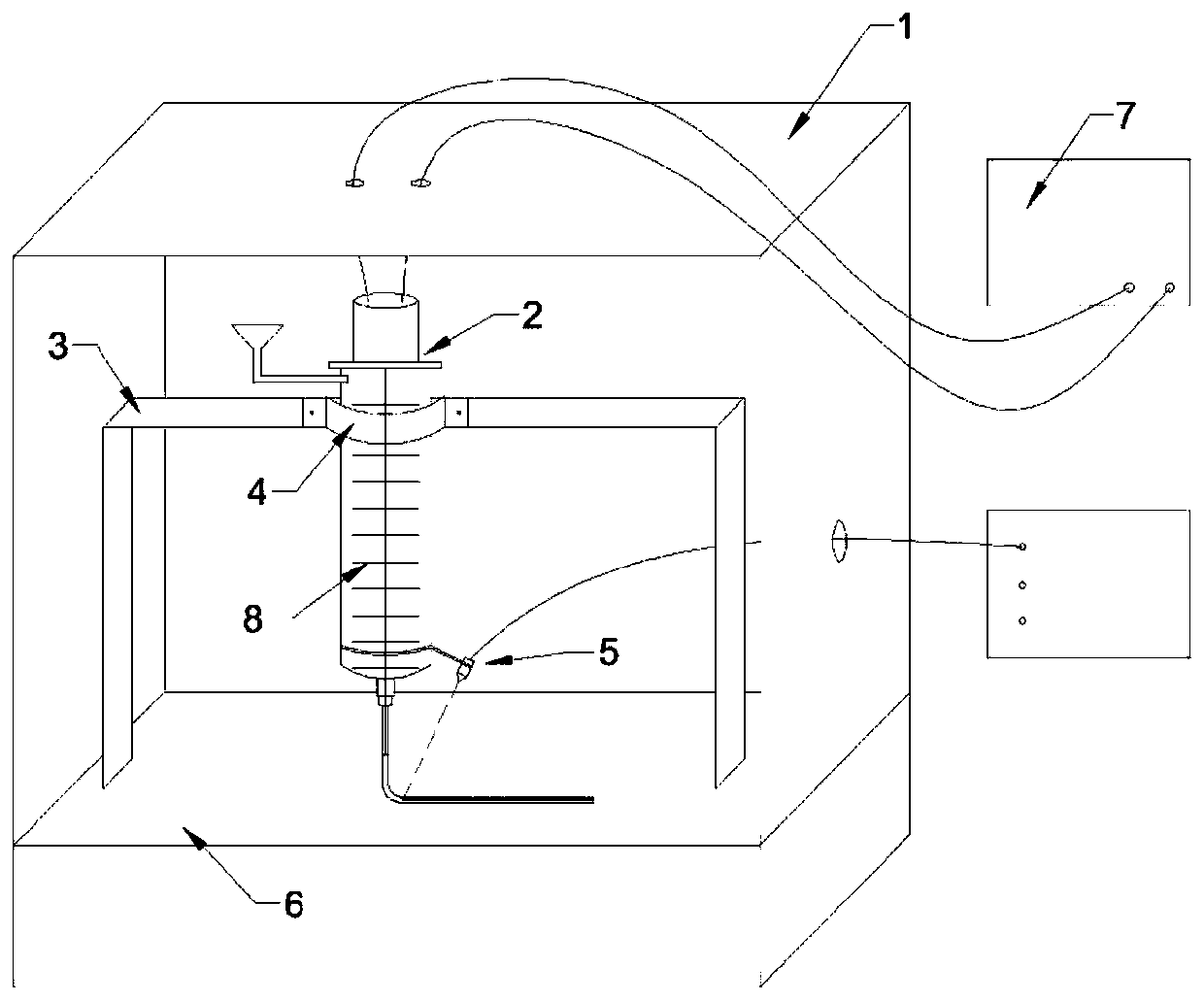

[0043] (3) Design the three-dimensional structure of the printed part, slice it in the computer slicing software, and import the sliced data into the attached figure 1 In the 3D printing control device (1) shown in;

[0044] (4) Injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com