Method for degrading corn straws

A technology of corn stalks and magnetic nanoparticles, applied in biochemical equipment and methods, fixed on or in inorganic carriers, fixed on/in organic carriers, etc. High production cost, deformation and inactivation, etc., to improve activity and stability, ensure cellulase activity, and increase affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

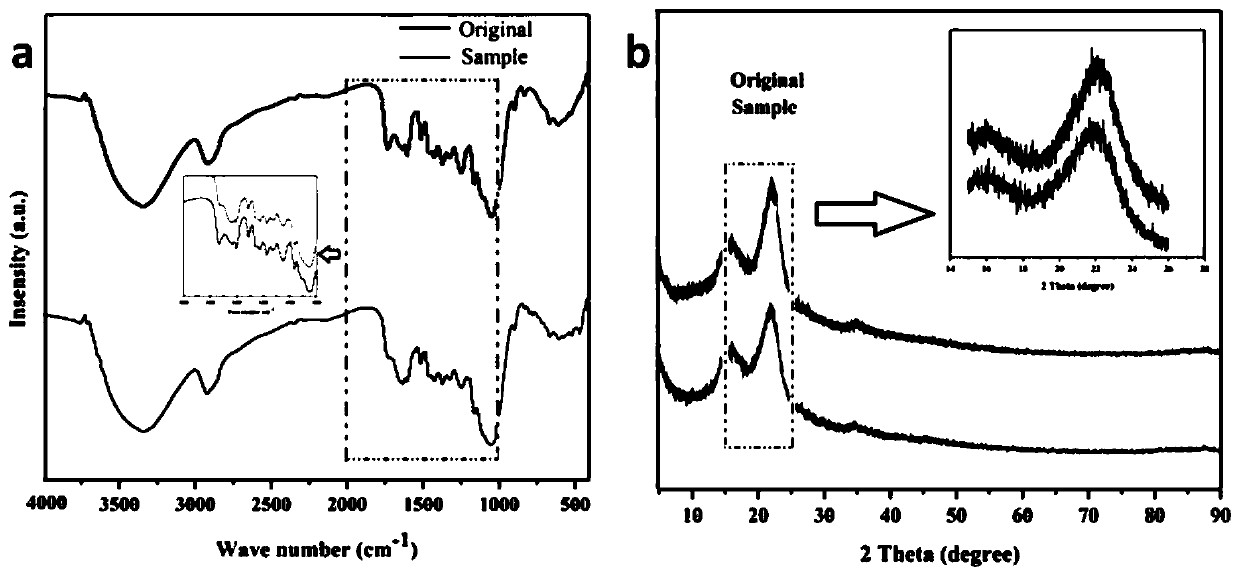

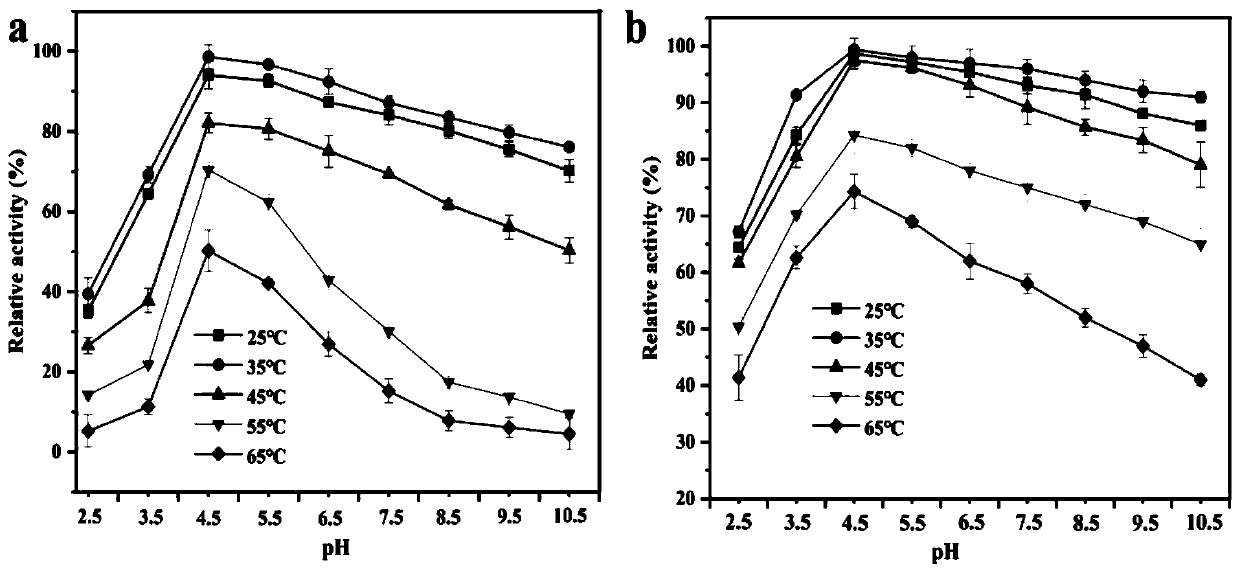

Method used

Image

Examples

Embodiment 1

[0045] A method for degrading corn stalks, comprising the following steps:

[0046] (1) After the corn stalks are mechanically crushed, pass through a 40-mesh sieve, and then dry at 105° C. for later use;

[0047] (2) Cu 2+ Modified Fe 3 O4-NH 2 -PEI magnetic nanoparticles were dissolved in NaAC-HAC buffer solution containing laccase, and treated with shaking at 150 rpm for 40min at 25°C; after the reaction, the prepared Cu 2+ Modified Fe 3 O4-NH 2 - PEI laccase magnetic nanoparticles and supernatant separation; ultrapure water for Cu 2+ Modified Fe 3 O4-NH 2 -PEI laccase magnetic nanoparticles were washed continuously until no laccase activity was detected in the detergent; the pH of NaAC-HAC buffer was 4.6, the concentration of laccase was 0.5mg / mL, Cu 2+ Modified Fe 3 O4-NH 2 -The mass volume ratio of PEI magnetic nanoparticles to NaAC-HAC buffer solution is 1mg: 10mL;

[0048] (3) Shake the immobilized laccase prepared in step (2), the corn stalks treated in ste...

Embodiment 2

[0052] A method for degrading corn stalks, comprising the following steps:

[0053] (1) After the corn stalks are mechanically crushed, pass through a 40-mesh sieve, and then dry at 105° C. for later use;

[0054] (2) Immobilize laccase on Cu 2+ Modified Fe 3 O4-NH 2 -On PEI magnetic nanoparticles, immobilized laccase was formed, specifically Cu 2+ Modified Fe 3 O4-NH 2 -PEI magnetic nanoparticles were dissolved in NaAC-HAC buffer solution containing laccase, and shaken at a rate of 150 rpm for 70 min at 25°C; after the reaction, the prepared Cu 2+ Modified Fe 3 O4-NH 2 - PEI laccase magnetic nanoparticles and supernatant separation; ultrapure water for Cu 2+ Modified Fe 3 O4-NH 2 -PEI laccase magnetic nanoparticles were washed continuously until no laccase activity was detected in the detergent; the pH of NaAC-HAC buffer was 4.6, the concentration of laccase was 4mg / mL, Cu 2+ Modified Fe 3 O4-NH 2 -The mass volume ratio of PEI magnetic nanoparticles to NaAC-HAC b...

Embodiment 3

[0059] A method for degrading corn stalks, comprising the following steps:

[0060] (1) After the corn stalks are mechanically crushed, pass through a 40-mesh sieve, and then dry at 105° C. for later use;

[0061] (2) Immobilize laccase on Cu 2+ Modified Fe 3 O4-NH 2 -On PEI magnetic nanoparticles, immobilized laccase was formed, specifically Cu 2+ Modified Fe 3 O4-NH 2 -PEI magnetic nanoparticles were dissolved in NaAC-HAC buffer solution containing laccase, and shaken at a rate of 150 rpm for 50 min at 25°C; after the reaction, the prepared Cu 2+ Modified Fe 3 O4-NH 2 - PEI laccase magnetic nanoparticles and supernatant separation; ultrapure water for Cu 2+ Modified Fe 3 O4-NH 2 - PEI laccase magnetic nanoparticles were washed continuously until no laccase activity was detected in the detergent; the pH of NaAC-HAC buffer was 4.6, the concentration of laccase was 20.5 mg / mL, Cu 2+ Modified Fe 3 O4-NH 2 -The mass volume ratio of PEI magnetic nanoparticles to NaAC-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com