Premixed flour for buckwheat steamed buns and production process thereof

A production process and premixed powder technology, applied in the field of buckwheat steamed bread premixed powder and its production technology, can solve the problems of high-content buckwheat steamed bread, bitter and rough taste, poor quality of buckwheat steamed bread premixed powder, and increased fatty acid value, and achieve effective Facilitate digestion and absorption, retain nutritional value, and reduce the effect of fatty acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1. Preparation of buckwheat steamed bread premix powder:

[0062] Formula: wheat flour 70%, buckwheat flour 15%, extruded buckwheat flour 15%, microencapsulated highly active dry yeast 0.9%, sodium stearoyl lactylate 0.1%, calcium stearoyl lactylate 0.2%, vitamin C 0.01%, Arabinoxylanase 0.002%, glucose oxidase 0.001%, α-amylase 0.001%.

[0063] Prepare the production technology of above-mentioned buckwheat steamed bread premix powder, comprise the following steps:

[0064] 1) The buckwheat grains are ground and then extruded and extruded. The extruded parameters are set as solid material feeding rate 16kg / h, moisture content 14%, extruder screw speed 190 Rpm. The puffing temperature is set to 85°C in zone II, 120°C in zone III, 170°C in zone IV, 140°C in zone V, and 130°C in zone VI;

[0065] 2) the extruded puffed buckwheat flour prepared in step 1) is ultrafinely pulverized;

[0066] 3) The extruded and puffed buckwheat flour and buckwheat flour prepared in step 2...

Embodiment 2

[0078] Formula: 70% wheat flour, 25% buckwheat flour, 5% extruded buckwheat flour, 0.9% microencapsulated highly active dry yeast, 0.1% sodium stearoyl lactylate, 0.2% calcium stearoyl lactylate, 0.01% vitamin C, Arabinoxylanase 0.002%, glucose oxidase 0.001%, α-amylase 0.001%.

[0079] Referring to Example 1, the formula was replaced with the above formula, and other conditions remained unchanged, and buckwheat steamed bun premix powder and its finished buckwheat steamed bun were prepared.

[0080] The buckwheat steamed bread obtained in Example 1-2 was subjected to a performance test, and the results are shown in Table 1.

[0081] test methods:

[0082] Preparation and determination of properties of buckwheat steamed bread:

[0083] Use a slicer to cut the steamed buns longitudinally into slices about 12.5mm thick each, and take the two central slices, use the TA-XT2i texture analyzer, select the P / 25 probe to test the hardness and chewiness of buckwheat steamed buns in TP...

Embodiment 3

[0099] Embodiment 3: process optimization

[0100] 1) Effects of different moisture contents on the storage stability of buckwheat steamed bread premix powder:

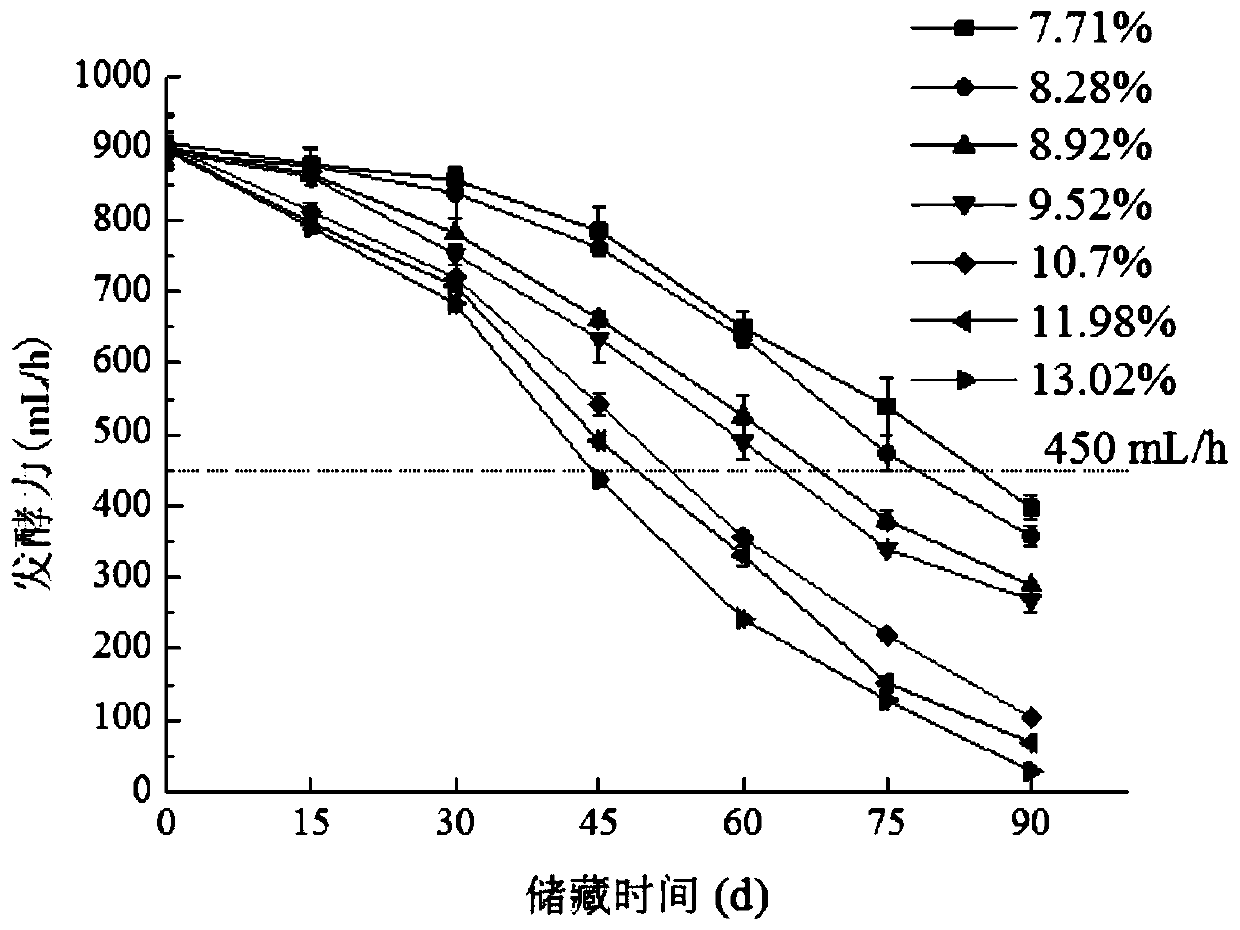

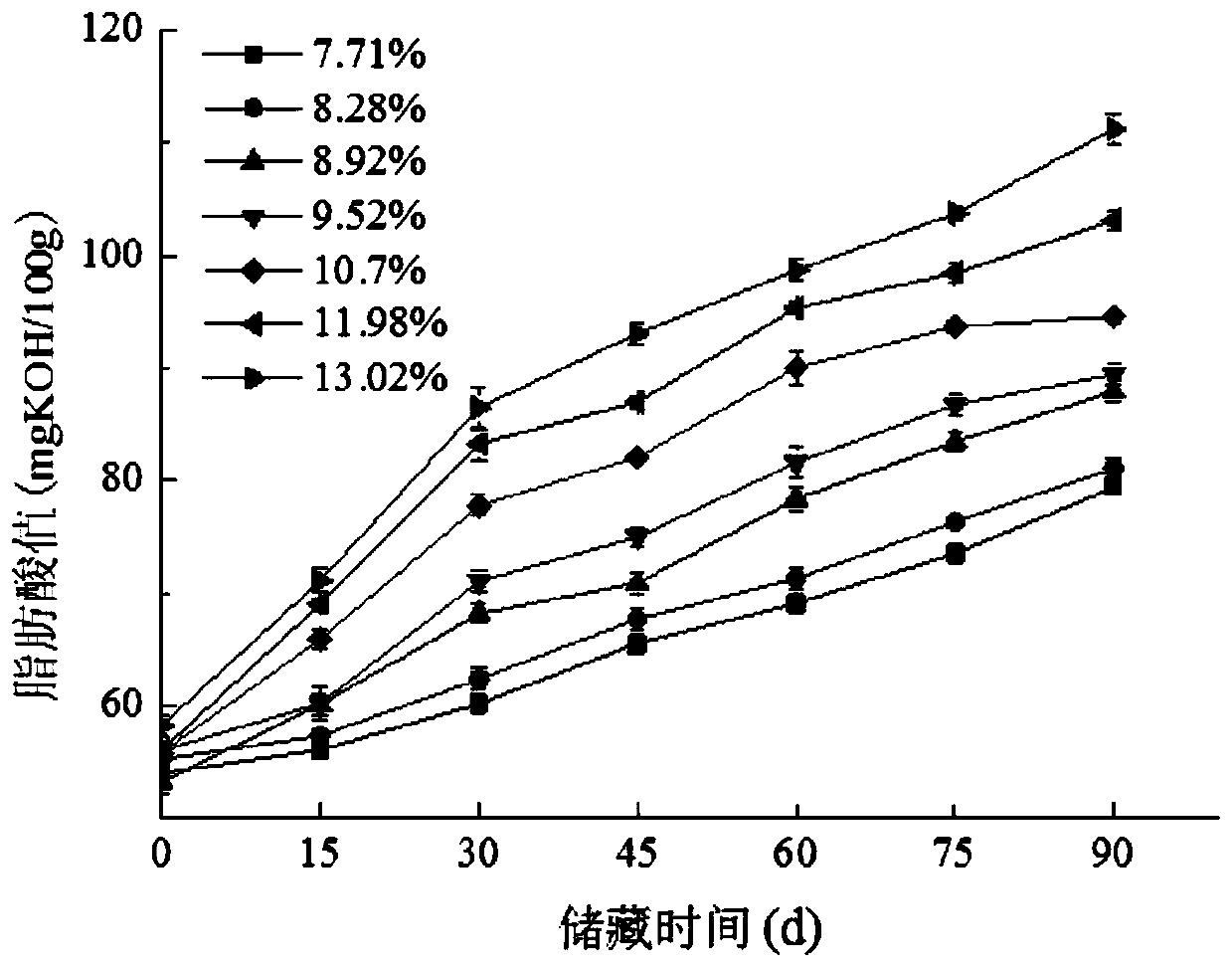

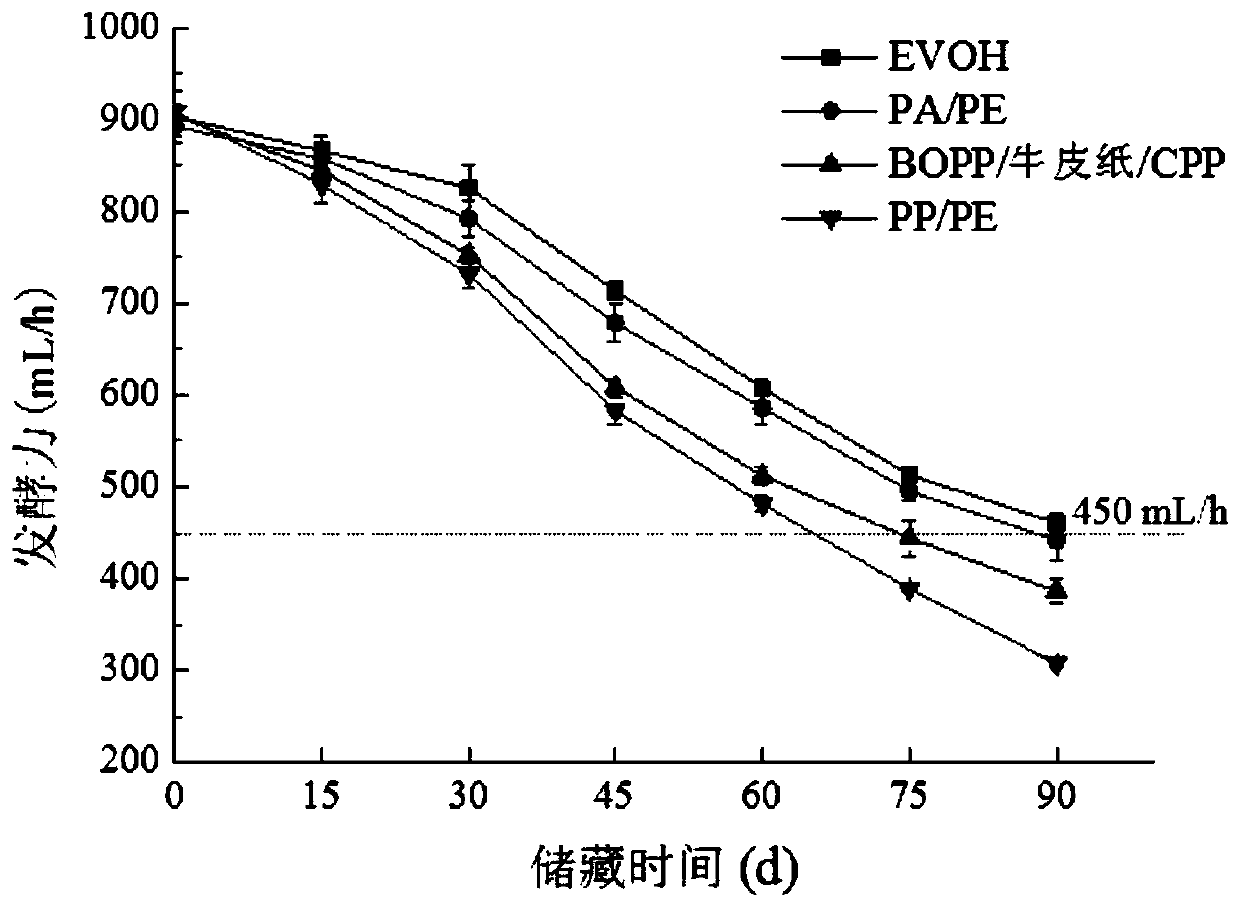

[0101] Referring to the process and formula of Example 1, the moisture content of the ready-mixed powder was respectively reduced to 7%-13%, and then the mixed powder with different moisture content was mixed with yeast, improver, etc. and placed in PE sealed bags for packaging. At this time, the ready-mixed powder does not use packaging materials with high barrier properties.

[0102] The result is as figure 1 and figure 2 It was shown that with the decrease of the moisture content of the premix powder, the fermentability of the buckwheat steamed bread premix powder decreased slowly, and the yeast inactivation rate decreased, and the lower the moisture content, the slower the increase of the fatty acid value. According to the requirements of the national standard GB / T 20886-2007, the fermentation power of high-ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com